Page 8

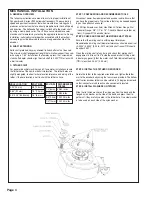

1. Locate the torque arm mounting hole on the motor side of the encoder. Insert the 10-32 bolt through the rod end of the torque arm.

Tighten the 10-32 bolt to 40 in-lbs.

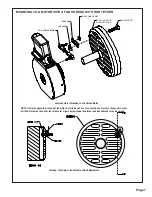

2. Arrange the anchor bolt (1/4 bolt) and lug. Slide the anchor bolt head into the fan shroud through an available vent slot.

3. Rotate the bolt 90° so that the anchor bolt catches to the inside of the fan shroud. Align lug to form a straight line from shaft to anchor.

Once positioned, tighten the hex nut with approximately 25in-lbs torque.

4. Slide the HT55, with the split shaft collar and torque arm loosely attached, over the motor shaft. While installing the encoder, engage the

torque arm by inserting the 10-32 x 1/2” hex bolt into the tapped hole in the bracket. Tighten to 40 in-lbs.

5. Without the encoder being completely tightened, set the axial alignment so that no part of the torque arm assembly touches the motor,

but is perpendicular to the encoder body. Position should be as close to C-face as possible but not flush with motor.

6. Tighten 10-32 x 1/2” bolt, in bracket to 40 in-lbs.

7. Tighten socket head cap screws, in split shaft collar, to 50 in-lbs. (Try maintaining the split in the shaft collar with notches in the motor

mounting sleeve on the HT55.)

NOTE: Verify installation by checking clearance between the torque arm assembly and motor C-face. The minimum motor shaft length

required should be approximately 1.6 ”.

MOUNTING TO A MOTOR WITH A FAN SHROUD (CONT.)