Important Safety Instructions

4

WARNING

- Risk of Injection or Injury to Persons - Do Not Direct Discharge Stream at Persons. -

Do not use a hose if exterior damage is evident.

- Risk of explosion. - Do not spray flammable liquids. - Do not operate in a flammable

environment.

CAUTION

- Gun kicks back. Hold with both hands.

- To reduce the risk of injury, read operating instructions carefully before use.

WARNING

- When using this product basic precautions should always be followed, including the following:

1.) Read all the instructions before using the product.

2.) To reduce the risk of injury, close supervision is necessary when the product is used near children. Do

not allow irresponsible use by children. Always stop the product and bleed pressures before leaving

unattended, disconnecting hoses or servicing the pump.

3.) Know how to stop the product and bleed pressures quickly. Be thoroughly familiar with the controls.

4.) Stay alert - watch what you are doing.

5.) Do not operate the product when fatigued or under the influence of alcohol or drugs.

6.) Keep operating area clear of all persons.

7.) Do not overreach or stand on unstable support. Keep good footing and balance at all times. Wear

footwear capable of maintaining a good grip on wet surfaces - Do not place the machine on soft or

unstable ground.

8.) Follow the maintenance instructions specified in all manuals. Do not run machine without sufficient

lubrication or sufficient water to cool the pump.

9.) Wear safety glasses, gloves, face protection and appropriate clothing when operating the machine.

10.) Do not operate this machine with broken or missing parts. - Never alter the manufacturer’s original

design or deactivate any safety device on the machine.

11.) Risk of exposure to dangerous chemicals. Wear protective gloves when handling and cleaning with

chemicals. Follow the chemical manufacturer’s directions. Understand all safety hazards and first aid

for all chemicals being used. Check whether dangerous chemicals have been used and take any

precautions that may have been recommended by the supplier of these chemicals when cleaning filters.

Do not pump highly abrasive fluids or use with incompatible chemicals or solvents.

12.) Know the pressure and temperature limits of your machine. Be sure all high pressure accessories meet

or exceed your machine’s limits. Do not set the pressure relief valve above the machine’s limit.

13.) Do not move this machine by pulling on the hose. Do not use the pump to support other items of

equipment that impose unacceptable loads on the pump. Do not attempt to use this machine as a prop.

14.) To reduce risk of injury, do not secure the spray gun open. Your spray gun is equipped with a built-in

trigger safety latch to guard against accidental trigger release and potentially dangerous high pressure

spray. Rotate the safety latch to the locked position when not spraying.

15.) Do not clean this machine with its own spray. Cleaning should be done with a damp sponge with the

motor OFF.

16.) Always make sure all switches and controls are in the OFF position prior to plugging in the electrical

cord. Do no stand in water while plugging and unplugging electrical cord.

17.) This product is provided with a ground fault circuit interrupter built into the power cord plug. If

replacement of the plug or cord is needed, use only identical replacement parts.

SAVE THESE INSTRUCTIONS

Summary of Contents for A1573001

Page 2: ...Hazard Signal Word Definitions 2...

Page 6: ...Pump Component Identification 6 A157306 A1573001 A1573021 A1573011 A1575581...

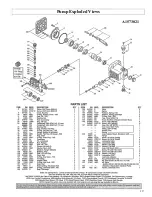

Page 14: ...Parts Explosion MA1573001 Rev A 1 14...

Page 16: ...Pump Exploded Views 16 A1573001...

Page 17: ...Pump Exploded Views 17...

Page 18: ...Pump Exploded Views 18 A1573011...

Page 19: ...Pump Exploded Views 19 A1573021...

Page 20: ...Pump Exploded Views 20 A157306...

Page 21: ...Pump Exploded Views 21...

Page 22: ...Pump Exploded Views 22 A1575581...

Page 23: ...23 This page has intentionally been left blank...