18

connect fitting on the main compressor outlet or after the

user installed regulator.

CAUTION: Air tools hazard

Do not attach air tools to open end of the hose until

start-up is completed and the unit checks out OK.

Quick Connect Procedure:

Keep finger off tool or activation switch until ready

to use.

Pull quick connect collar back (Figure 14a).

Push hose or attachment firmly against stop.

Let go of collar (Figure 14a).

Pull and rotate slightly (hose or attachment) to

assure a tight connection.

WARNING: Projectile hazard

Air tool or attachment can become a projectile and

cause serious personal injury or damage if not securely

attached to the air hose.

Figure 14a

Figure 14b Figure 14c

Using Compressor for Spraying

Flammable Materials

Always follow precautions on container labels or MSDS’

before spraying flammable materials, such as paint.

Moisture in Compressed Air

Moisture in supply air when compressed will form into

droplets as it leaves air compressor pump and enters

receiver tank. When humidity is high or when a

compressor is in continuous use for an extended period

of time, a significant amount of moisture will collect in

the tank. Part of the moisture will be discharged in the

outlet air.

When using a paint spray or sandblast gun, this water

will be carried from the tank through the hose, and out of

the gun as droplets mixed with the spray material. If this

is not acceptable for your application, an external air

dryer must be added to the system.

Shutdown

Procedure

When you are finished using the compressor:

1. Move the pressure switch to the OFF position.

2. Close the ball valve to stop airflow.

3. Unplug the power cord.

4. Operate tools briefly to release live pressure

5. Disconnect all tools.

6. Drain air receiver tank by pulling safety relief

valve.

7. After all storage air is discharges, disconnect

hoses and open the ball valve.

8. Once the tank pressure gauge registers under 10

PSI, open the drain valve on the bottom of the

tank to drain condensation moisture.

WARNING: Risk of bursting

Drain air receiver tank daily or after each use to prevent

moisture buildup in the air tank. Serious injury or death

may occur from a tank explosion caused by moisture

induced tank corrosion.

For Malfunction During Operation

Immediately turn off the compressor if any of the

following conditions arise during operation:

Excessive change in motor speed, slow or fast

Overheating

Excessive vibration

Unusual noise

Flame or smoke

Air leakage

Pull ring on safety valve to immediately relieve pressure.

WARNING: Shutdown hazards

Do not leave an operating machine unattended. Always

shut the machine OFF and relieve the pressure before

leaving the machine. NEVER disconnect the high-

pressure outlet hose from the unit while the tank and air

line are pressurized. A hazardous high pressure air

stream will result as receiver tank is quickly emptied.

Collar

Coupler

Quick Disconnect

Socket

Correct

Insertion

Not Fully

Inserted

Collar Seated

Collar NOT Seated

Tool

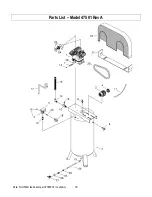

Summary of Contents for 47500

Page 23: ...23 Parts List Model 47500 Rev A Note NorthStar tank decal part 789000 no shown ...

Page 25: ...25 792363 Pump Exploded View ...

Page 28: ...28 Parts List Model 47501 Rev A Note NorthStar tank decal part 789000 no shown ...

Page 30: ...30 792373 Pump Parts List Wing nut for 30 not shown ...

Page 35: ...35 Assembled by Northern Tool Equipment Company Inc Burnsville MN 55306 NorthernTool com ...