12

2. The black, low pressure chemical nozzle must be

used to spray chemicals.

3. Squeeze the spray gun trigger. The chemical injector

will draw the chemical into the water stream.

4. Spray detergent onto the surface and allow it to soak.

Chemicals need time to work properly. Follow the

chemical manufacturer’s recommendations for the

recommended time.

5. Change back to high pressure to rinse by inserting

one of the high pressure nozzles.

6. Hold the lance with two hands in a sturdy stance

position.

7. Point lance at dirty surface and squeeze trigger.

8. Wash from the bottom to the top, using side to side

motions. This washes away heavy dirt and allows the

detergent to soak as you work toward the top.

9. Use the width of the spray pattern to wash in a wide

path. Overlap spray paths for complete coverage.

10.The nozzle should be 12” to 24” from the work, closer

for tough areas.

Caution: Be careful on painted or delicate surfaces,

the pressure may damage the surface if the nozzle is

too close.

11. Small parts should be washed in a basket so the

pressure does not push them away. Larger, light

weight parts should be clamped down.

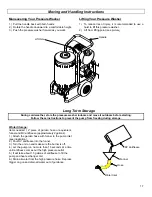

12. The pressure washer is set to the maximum rated

pressure when it leaves the factory. To adjust the

pressure, turn the unloader knob counter-clockwise.

WARNING: Do not alter the unloader valve’s

maximum pressure. Excess pressures could cause

serious injury and/or pump damage. Any alteration

other than turning the adjustment knob will void

your warranty.

For Steam (Optional)

1. Set the thermostat to 250

°

F.

2. Turn the Heat switch ON.

3. Insert the steam nozzle into the nozzle holder.

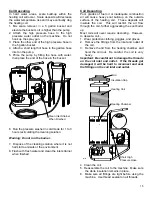

To Stop

1. If detergents were used, draw clear water through the

detergent inlet line to purge detergent. Failure to do

so may clog the chemical injector.

2. If the burner was used, turn off the “Heat” switch and

pump cold water through the coil for 3 minutes.

Insufficient cool down period of high pressure hose

will cause excessive wear and eventual rupturing of

hose.

3. Turn the pump switch OFF.

4. Turn OFF the water supply.

5. Squeeze the trigger to relieve the system pressure.

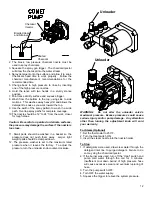

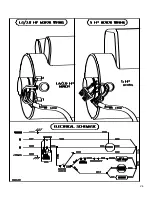

Diluted

Chemical

Braided Hose

and Strainer

Chemical

Injector

Unloader

Unloader

Summary of Contents for 157305

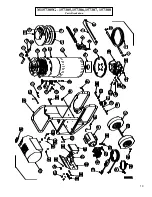

Page 19: ...19 M157305G 157305 157306 157307 157308 Parts Breakdown ...

Page 22: ...22 ...

Page 23: ...23 ...

Page 24: ...24 ...