4. AIR CONDITIONING APPLICATIONS

If the furnace is used in conjunction with air conditioning,

the furnace shall be installed in parallel with or upstream

from the evaporator coil to avoid condensation in the

heat exchanger. In a parallel installation, the dampers or

air controlling means must prevent chilled air from

entering the furnace. If the dampers are manually

operated, there must be a means of control to prevent

the operation of either system unless the dampers are in

the full heat or full cool position. The air heated by the

furnace shall not pass through a refrigeration unit unless

the unit is specifically approved for such service.

The blower speed must be checked and adjusted to

compensate for the pressure drop caused by the

evaporator coil. Refer to Appendix B for recommended

wiring and electrical connections of the air conditioning

controls.

5. COMBUSTION AIR

If the furnace is installed in a closet or utility room, two

openings must be provided connecting to a well-

ventilated space (full basement, living room or other

room opening thereto, but not a bedroom or bathroom).

One opening shall be located above the level of the

upper vent opening and one opening below the

combustion air inlet opening in the front of the furnace.

Each opening shall have a minimum free area of 1½

square inches per 1,000 Btu/h of total input rating of all

appliances installed in the room.

For furnaces located in buildings of unusually tight

construction, such as those with high quality weather

stripping, caulking, windows and doors, or storm sashed

windows, or where basement windows are well sealed, a

permanent opening communicating with a well ventilated

attic or with the outdoors shall be provided, using a duct

if necessary. The duct opening shall have a free area of

1½ square inches per 1,000 Btu/h of total input rating of

all appliances to be installed. When a furnace is installed

in a full basement, infiltration is normally adequate to

provide air for combustion and draft operation. Furnace

rooms under 65m³ (700 ft³) should automatically be

treated as confined space.

6. CHIMNEY VENTING

The flue pipe should be as short as possible with

horizontal pipes sloping upward toward the chimney at a

rate of one-quarter inch to the foot. The flue pipe should

not be smaller in cross sectional area than the flue collar

on the furnace. The flue pipe should connect to the

chimney such that the flue pipe extends into, and

terminates flush with the inside surface of the chimney

liner. Seal the joint between the pipe and the lining. The

chimney outlet should be at least two feet above the

highest point of a peaked roof. All unused chimney

openings should be closed. Chimneys must conform to

local, provincial or state codes, or in the absence of local

regulations, to the requirements of the National

Building Code.

NOTE: THE FURNACE IS APPROVED FOR

USE WITH TYPE L VENT OR EQUIVALENT.

CHIMNEY VENTED VERSIONS

OF THE

FURNACE MUST BE CONNECTED TO A

FLUE HAVING SUFFICIENT DRAFT AT ALL

TIMES TO ENSURE SAFE AND

PROPER

OPERATION OF THE APPLIANCE.

NOTE: THE RECOMMENDED FLUE DRAFT

PRESSURE IS -0.02 IN. W.C. (SEE FIG 2.)

The flue pipe must not pass through any floor or

ceiling, but may pass through a wall where suitable

fire protection provisions have been installed. Refer

to the latest edition of CAN/CSA B-139 for rules

governing the installation of oil burning equipment.

In the United States, refer to the latest edition of

NFPA 31 for regulations governing the installation of

oil burning equipment.

See appendix A for burner set-up.

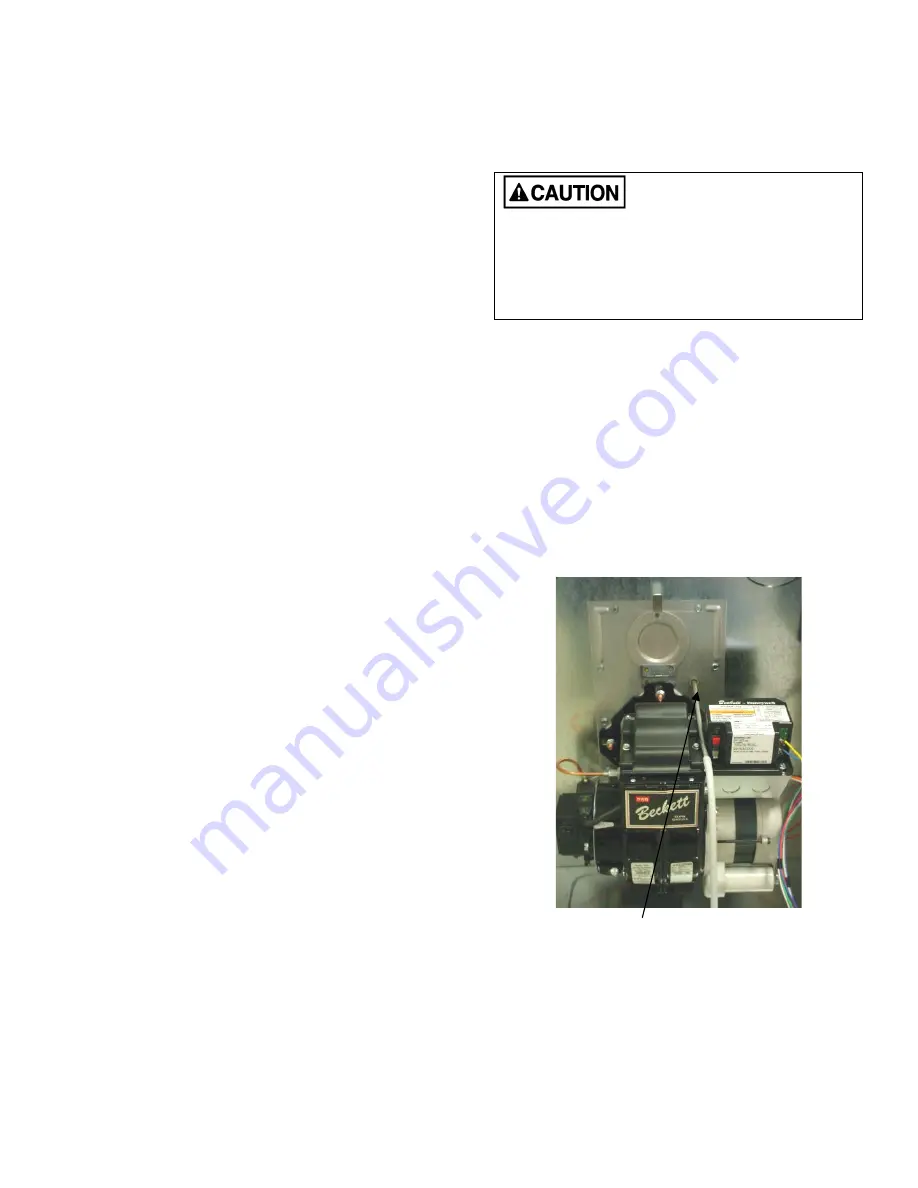

Fig. 2: Checking Over-Fire Draft.

Over-fire draft access port.

7. BAROMETRIC DAMPER CONTROL.

The barometric damper control, also known as a

draft regulator, is used on conventional chimney

venting only. This control automatically maintains a

constant negative pressure in the furnace to obtain

maximum efficiency. It ensures that proper

pressures are not exceeded. If the chimney does not

develop sufficient draft, the draft control cannot

4

Summary of Contents for O4HD-091A-12-FB

Page 34: ...34...