www.nordsonefd.com [email protected]

800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

EV Series Automated Dispensing Systems

97

Appendix E, Height Sensor Setup and Use

The optional height sensor can detect any variation from the original Z height program values from workpiece to

workpiece. If the Z height changes, the system detects the new Z height value and adjusts the program accordingly.

PREREQUISITES

The height sensor is installed and the cable is connected to the I/O port. Refer to the instructions provided with

the height sensor.

The system is properly set up. Refer to “Setting Up and Calibrating the System (Required)” on page 37.

A test workpiece is positioned on the fixture plate or work surface.

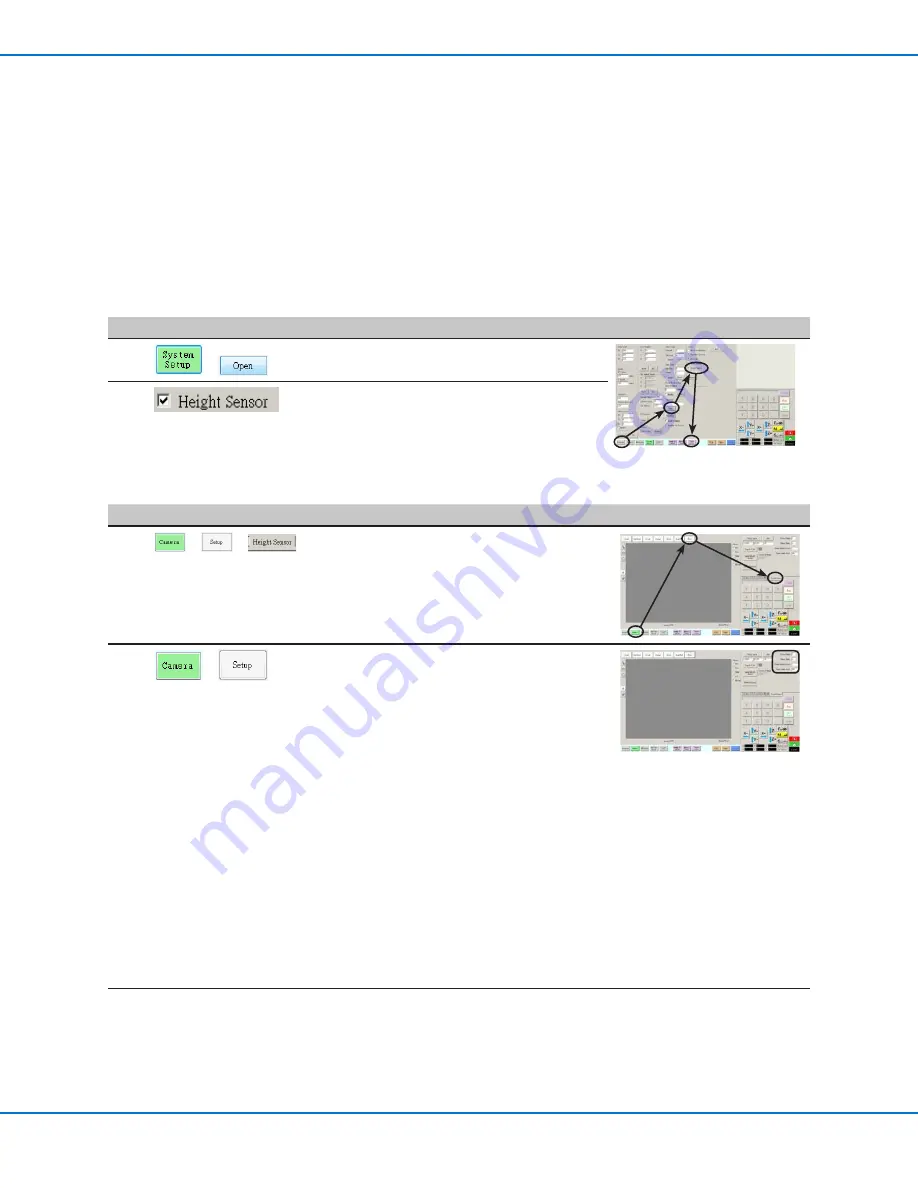

To Enable the Height Sensor

#

Click

Step

Reference Image

1

>

• Click the SYSTEM SETUP tab, then click

OPEN.

2

• Check HEIGHT SENSOR.

When the height sensor is enabled, the

Toggle Probe button appears in the tab bar.

To Set Up the Height Sensor

#

Click

Step

Reference Image

1

>

>

• Click the CAMERA tab, click SETUP at the

top of the Camera screen, and then click the

HEIGHT SENSOR tab.

The Height Sensor fields appear.

2

>

• In the fields located at the top right corner of

the Height Sensor area, enter the following

values:

- Probe Output: As connected on your

system (default = 8)

- Sensor Input: As connected on your

system (default = 8)

- Detect Speed (mm/s): 5 (range = 1–20)

- Travel Limit (mm): 20 (range = 1–100)

NOTES:

• Detect Speed is how fast the Z axis lowers

towards the workpiece after the height

sensor probe extends.

• Travel Limit is the range within which the

Z axis moves to detect the Z-height value.

Continued on next page