BIM 1030/2005/03

8

www.nord.com

LUBRICANT CAPACITY

Each reducer has the oil level and oil quantity adjusted according to the mounting position shown in the tables. When replacing the oil, consult

the tables below to determine the proper amount of oil to be installed according to the reducer size and mounting position. Note that this is

approximate and the final level will be adjusted when the reducer is installed. Acceptable oil fill level is within ½ inch of the bottom of the fill

plug threads

.

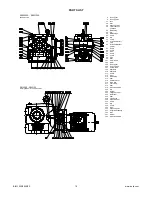

B3

B6I

B8 V1/V5I V6/V6I

B3I

B6

B6II

B8I

B5I B5III V1

V3

B5

B5II

H1

H2

H5

H6

H3

H4

SK 02040

quarts 0.48 0.48 0.63

0.53

0.53

0.63

0.63

0.69

0.63 0.53 0.79 0.53 0.53 0.85

0.63

0.42 0.69 0.53 0.53 0.63

0.85

liters 0.45 0.45 0.60

0.50

0.50

0.60

0.60

0.65

0.60 0.50 0.75 0.50 0.50 0.80

0.60

0.40 0.65 0.50 0.50 0.60

0.80

SK 02050

quarts 0.63 0.63 0.74

0.74

0.74

1.22

1.27

1.22

1.27 0.48 0.95 1.06 1.06 1.48

1.32

0.48 0.95 0.85 0.85 1.16

1.16

liters 0.60 0.60 0.70

0.70

0.70

1.15

1.20

1.15

1.20 0.45 0.90 1.00 1.00 1.40

1.25

0.45 0.90 0.80 0.80 1.10

1.10

SK 12063

quarts 0.42 0.42 1.27

1.06

1.06

1.64

1.80

1.64

1.80 0.53 1.48 1.59 1.59 1.69

1.90

0.53 1.27 1.16 1.16 1.48

1.53

liters 0.40 0.40 1.20

1.00

1.00

1.55

1.70

1.55

1.70 0.50 1.40 1.50 1.50 1.60

1.80

0.50 1.20 1.10 1.10 1.40

1.45

SK 12080

quarts 0.85 0.85 1.80

1.80

1.80

2.85

2.75

2.85

2.75 1.00 2.64 2.64 2.64 3.49

3.91

0.95 3.17 2.33 2.33 3.17

3.28

liters 0.80 0.80 1.70

1.70

1.70

2.70

2.60

2.70

2.60 0.95 2.50 2.50 2.50 3.30

3.70

0.90 3.00 2.20 2.20 3.00

3.10

SK 32100

quarts 1.69 1.69 3.59

3.38

3.38

5.71

5.81

5.71

5.81 1.59 5.18 4.65 4.65 7.50

7.50

1.59 4.02 4.02 4.02 5.60

5.50

liters 1.60 1.60 3.40

3.20

3.20

5.40

5.50

5.40

5.50 1.50 4.90 4.40 4.40 7.10

7.10

1.50 3.80 3.80 3.80 5.30

5.20

SK 42125

quarts 2.96 2.96 6.55

6.13

6.13

10.89 11.63 10.89 11.63 3.49 6.45 7.19 7.19 11.84 10.99 3.38 6.45 6.66 6.66 11.10 13.64

liters 2.80 2.80 6.20

5.80

5.80

10.30 11.00 10.30 11.00 3.30 6.10 6.80 6.80 11.20 10.40 3.20 6.10 6.30 6.30 10.50 12.90

SK 13050

quarts 1.00 1.00 1.16

1.00

1.00

1.53

1.64

1.53

1.64 0.95 1.22 1.32 1.32 1.90

1.85

0.90 1.32 1.22 1.22 1.43

1.85

liters 0.95 0.95 1.10

0.95

0.95

1.45

1.55

1.45

1.55 0.90 1.15 1.25 1.25 1.80

1.75

0.85 1.25 1.15 1.15 1.35

1.75

SK13063

quarts 0.90 0.90 1.69

1.32

1.32

2.11

2.43

2.11

2.43 1.00 1.74 1.85 1.85 2.22

2.27

0.95 1.64 1.53 1.53 2.22

2.22

liters 0.85 0.85 1.60

1.25

1.25

2.00

2.30

2.00

2.30 0.95 1.65 1.75 1.75 2.10

2.15

0.90 1.55 1.45 1.45 2.10

2.10

SK 13080

quarts 1.80 1.80 2.22

2.06

2.06

3.59

3.38

3.59

3.38 1.48 2.91 2.91 2.91 4.44

4.44

1.80 3.81 2.70 2.70 3.81

3.96

liters 1.70 1.70 2.10

1.95

1.95

3.40

3.20

3.40

3.20 1.40 2.75 2.75 2.75 4.20

4.20

1.70 3.60 2.55 2.55 3.60

3.75

SK 33100

quarts 2.22 2.22 4.23

3.91

3.91

7.19

8.03

7.19

8.03 2.43 5.81 5.13 5.13 8.03

8.24

2.22 5.07 4.44 4.44 6.98

6.45

liters 2.10 2.10 4.00

3.70

3.70

6.80

7.60

6.80

7.60 2.30 5.50 4.85 4.85 7.60

7.80

2.10 4.80 4.20 4.20 6.60

6.10

SK 43125

quarts 8.24 8.24 7.61

7.08

7.08

14.27 14.80 14.27 14.80 4.55 7.50 8.14 8.14 13.64 12.79 5.07 7.82 8.46 8.46 15.33 14.27

liters 7.80 7.80 7.20

6.70

6.70

13.50 14.00 13.50 14.00 4.30 7.10 7.70 7.70 12.90 12.10 4.80 7.40 8.00 8.00 14.50 13.50

Note: Filling quantities are approximate figures. Oil level must be checked according to oil level plug after final installtion.

Acceptable oil fill level is within 1/2 inch of the bottom of the fill plug threads. For mounting angles not shown, consult factory.

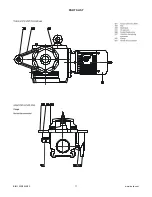

OIL FILL QUANTITIES

Vertical

SHAFT MOUNT UNIT

Horizontal

Vertical

FOOTED UNIT

Horizontal

FLANGED UNIT

Horizontal

Vertical