0353750

Nokka Oy

Teollisuustie 4

P.O. Box 4, FIN-40950 Muurame, Finland

Tel. +358 44 7624 500

Tex. +358 14 3100 205

www.nokka.fi

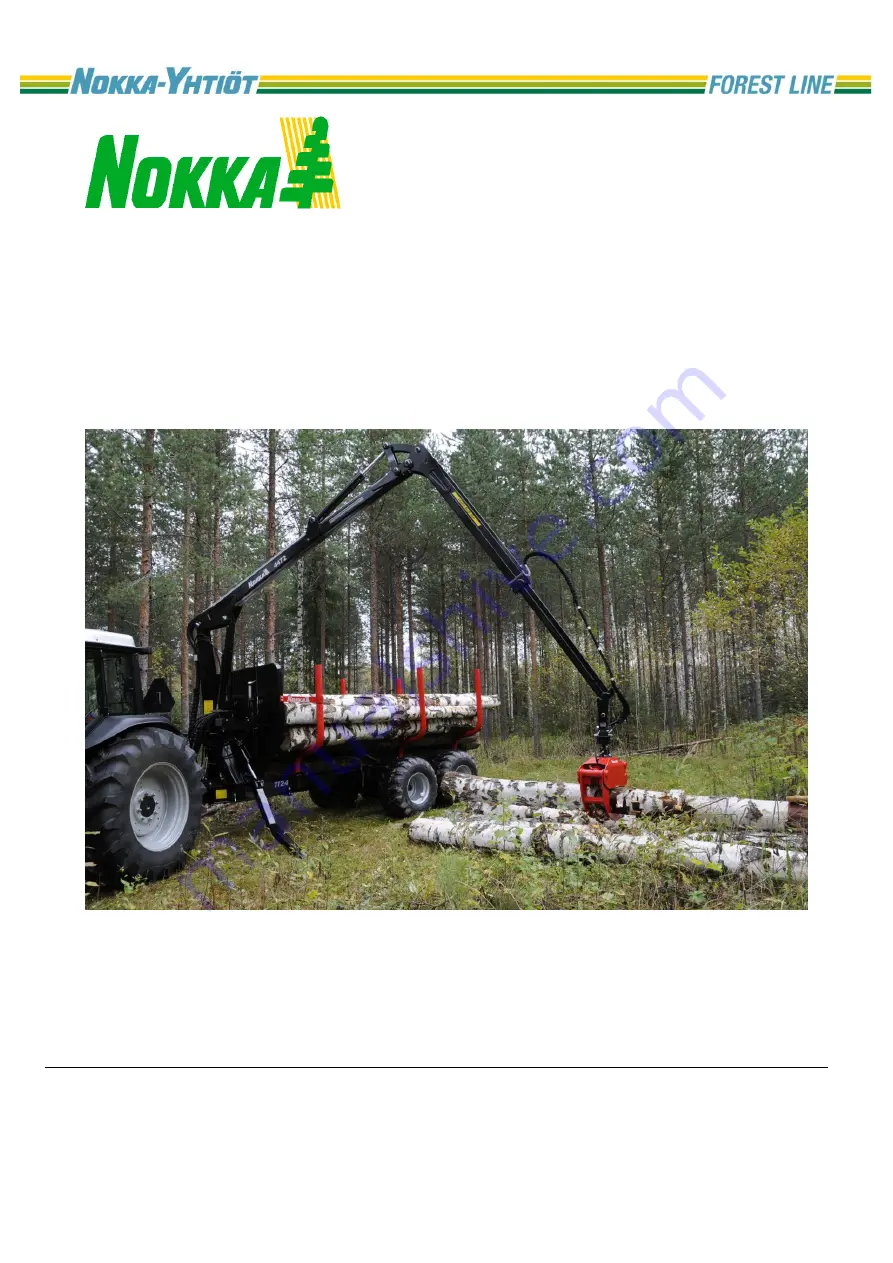

1042P, 3767P LT, 3767P HT, 4872P

4780P, 4970, 4976, 5269, 5282, 6084

GRAPPLE LOADER

Installation, operation and

maintenance

manual