18

•

Use approved and from your dealer released original spare parts.

•

Please consider that oil leakage of hydraulic fluid can cause failures and accidents.

•

It is allowed to adjust the pressure valve only from trained service technicians.

•

Waste material like oil, used batteries or other must be probably disposed and recycled

according to the national regulations and if necessary brought to a recycling company.

•

All bushings and bearings have been lubricated at the factory. To increase their life,

regular maintenance is recommended. Using the appropriate grease for the application

and lubricate each grease fitting every 6 months.

•

Harsh environments may require more frequent maintenance.

If you need to change the wheels, please follow the instructions above. The wheels must be round and

they should have no abnormal abrasion. By changing the wheels secure the truck by using dedicated

equipment.

a.

Maintenance Checklist

DAILY

•

Follow chapter 5.

MONTHLY

•

All bearings and shafts are provided with long- life grease at the factory. Long-life grease should be

applied to the lubrication points at monthly intervals or after each time the truck is cleaned.

•

Clean off dirt and debris.

EVERY THREE MONTH

•

Check the set-up of the drain-valve

ANNUALLY

•

Change the oil (more frequently if color has substantially darkened or feels gritty). The required

hydraulic fluid type is ISO VG32, its viscosity should be 30cSt at 40°C, total volume is about 1 - 1.3 l.

•

Check all parts of the truck for wear and replace defective parts where necessary.

NOTE: If hydraulic oil is milky white in color, water is in the hydraulic system. Change the hydraulic oil

immediately.

Before starting operating the truck, ensure that all markings and decals are on the right

place and not damaged (acc. to Fig. 3). If necessary replace the decals.

b.

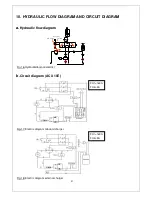

Deaeration of the hydraulic system

Air may find its way into the pump during transportation, tilting or usage on uneven ground. It can result in

not elevating forks whilst pumping in the

Raise

position. The air can be removed in the following way:

Move the control handle to the

Lower

position, move then the tiller down several times. Thereafter normal

operation can be resumed.