5

SENSOR

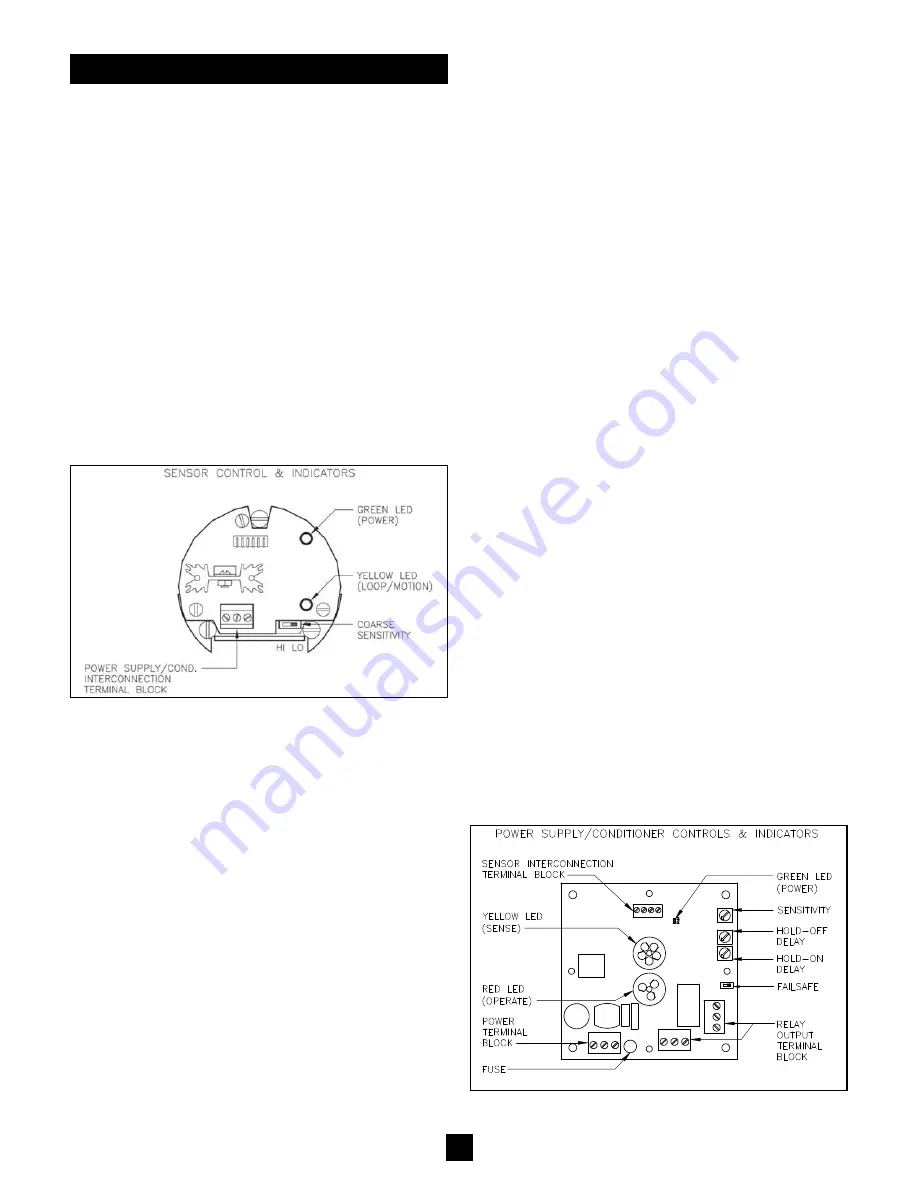

(See Figure 11)

Coarse Sensitivity

- The coarse sensitivity is a slide switch

which permits selection of “HI” or “LO” settings. This selection

operates in tandem with the main sensitivity adjustment found in

the power supply/conditioner. The sensor is provided with the

coarse sensitivity switch placed in the “LO” setting which will sat-

isfy most applications. The status of the coarse sensitivity can

be changed to “HI” if the adjustability range found on the power

supply/conditioner is inadequate. (See Calibration of Power

Supply/Conditioner.)

SENSOR INDICATORS

1) Green LED

- Illumination of the Green LED indicates that

power is properly connected to the sensor. Lack of illumination

could be from lack of supplied power or reversing the polarity of

the input connections.

2) Yellow LED

- Any illumination of the Yellow LED indicates that

the “SIG” connection loop is correctly installed. Lack of illumi-

nation could be from improper connection between the sensor

and power supply/conditioner. Detected motion will cause the

Yellow LED to more intensely illuminate.

CALIBRATION

Figure 11

Figure 12

2) Material Density in the Pipe/Chute

- As more product is

placed in motion, the amount of disturbance which is analyzed

as motion also increases. Thus, applications which have signif-

icant material flow can tolerate a lower sensitivity setting then

those applications with minimal material flow.

3) Material Dielectric Constant

- Microwave propagation is

affected by the dielectric constant of the material being sensed.

Typically, low dielectric materials tend to absorb/pass the energy

while high dielectrics tend to reflect the energy. The SFD-2 will

sense material better when energy is reflected. Therefore, low

dielectric materials (i.e. plastics, soap, cement) will require a

greater sensitivity setting than high dielectric materials (i.e.

grains, feed, ores)

4) Material Particle Size

- Microwaves have a particular wave-

length and therefore are more easily reflected when hitting larg-

er particle sizes. Thus, applications with small particle sizes (i.e.

powders) will require a greater sensitivity setting than large par-

ticle sizes (i.e. granulars).

5) Mounting Environment

- When microwave energy is

entrapped within metal containers, internal reflections are pro-

duced therefore creating a increased probability to see material

motion. Thus applications utilizing metallic pipes/chutes require

a lower sensitivity setting than applications utilizing non-metallic

pipes/chutes. Also, since microwave energy losses its power

density with respect to traveled distance, applications utilizing

small diameter pipes/chutes require a lower sensitivity setting

than applications utilizing large diameter pipes/chutes.

2-STEP CALIBRATION

1) While the system is operating (conveyors, augers, etc.) but no

material is flowing, rotate the sensitivity adjustment clockwise

until the “sense” (Yellow) LED illuminates. Note the adjustment

position. (On most applications, this will occur near the 4 o’clock

position).

2) With the material flowing, rotate the adjustment counter-clock-

wise until the “sense” (Yellow) LED turns off. Note the adjust-

ment position. Reposition the sensitivity adjustment at the

halfway point between the LED “on” and LED “off” settings.

(NOTE: If the difference between the two conditions is very

small, thereby making final calibration difficult, reposition the

sensor’s coarse sensitivity setting to the “HI” position and repeat

the 2-Step Calibration procedure. (See Calibration of the

Sensor.) In general, applications which are difficult to sense will

require a greater clockwise setting.

POWER SUPPLY/CONDITIONER

(See Figure 12)

Sensitivity

- A single-turn potentiometer is used to adjust how

sensitive the SFD-2 will be to objects in motion. The poten-

tiometer permits adjustment between the 7 o’clock and 5 o’clock

positions (300 degrees of rotation). Physical stops exist at both

extremes of the adjustment. A fully counter-clockwise adjust-

ment (7 o’clock) creates a very insensitive setting where nearly

all motion is ignored. A fully clockwise adjustment (5 o’clock)

creates the greatest sensitivity. In addition, this setting forces the

power supply/conditioner into the “sense” condition regardless of

motion presence. Ideal adjustment can be achieved via a sim-

ple “2-Step Calibration” procedure. The setting and the ability of

the SFD-2 to sense material is influenced by the mechanical

mounting (See Pre-Installation Considerations) as well as mate-

rial characteristics such as velocity, flow density, dielectric con-

stant, and particle size.

1) Material velocity

- Electronic signal conditioning enables

the sensor to see faster moving material easier than slow mov-

ing material. This is particularly important when distinguishing

between typical material movement and extraneous influences

such as augers, conveyors, etc. Generally, the slower the mate-

rial movement, the greater the sensitivity setting must be.