3

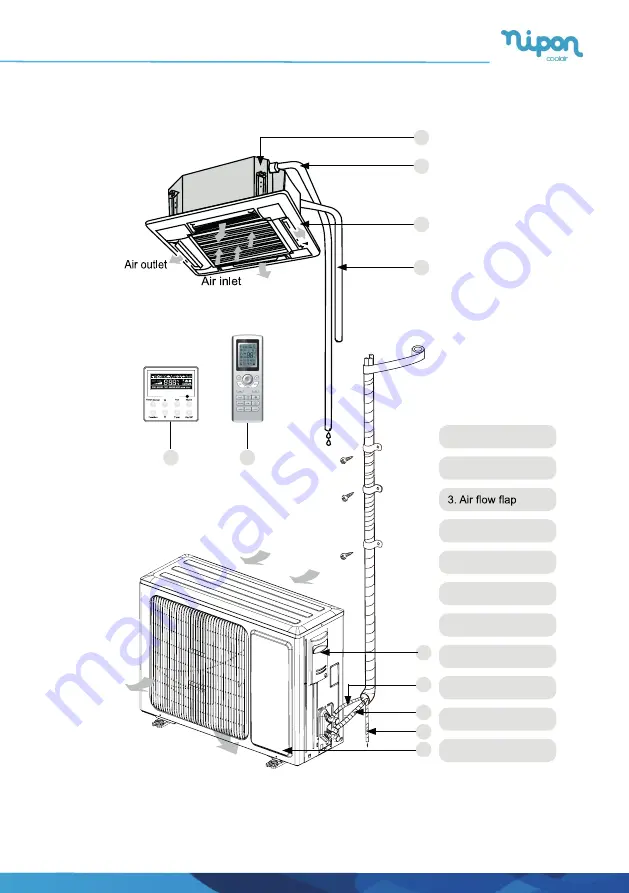

2 Outline of the Unit and Main Parts

1. Drainage device

2. Drainage pipe

4. Connection pipe

5. Wired Controller

6. Wireless Controller

7. Big handle

8. Liquid Pipe

9. Gas pipe

10. Drainage pipe

11. Front Board

Indoor

Outdoor

2

3

4

7

5

6

1

8

9

10

11

Air inlet

Air outlet

Fig.1

Cassete - Multi-Split