This document may be subject to change

Side 7 of 24

Ducting

We recommend that there are used ducts and fittings with rubber packing that meet sealing class

B and that the connections between the unit and the ducting are made with 1 metre sound absorb-

ing flexible transitions as regards sound reduction.

The ducts should be shortened with a hacksaw or an angle grinder and laid out according to the

working drawing. The ducts are typically laid out on the main beam of the truss frame and are se-

cured with hole belts or they are being hanged in assembly belts. Please avoid any unnecessary

area reductions and breaks of the ducting.

The ducts should be insulated – in some cases with the ordinary attic-insulation. All ducts should

be insulated with 100mm mineral wool to avoid heat loss and condensation. This also applies for

flexible transitions. It is recommended that the insulation is carried out with 2 layers of 50mm. If the

ducts are laid out in an unheated room it will cause condensation problems if the unit are turned off

for a longer period of time as the hot air from the heated room will rise to the ducts and cause con-

densation which can cause damp problems.

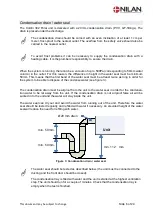

Figure 4: Insulation of ducting

The discharge duct is leading the exhaust air away either above the roof or through the outer wall.

It is important that the roof cowl has at least the same open space as the duct leading to the roof

cowl. A reduction at this place will cause an unnecessary pressure drop which can lead to a re-

duced ventilation output.

The holes for the inlet- and exhaust valves should be cut according to the mounting-frame for the

prescribed valve. The frame for the valve must be secured with screws before placing the valve in

the frame. The valves are placed in accordance with the size, construction and use of the room. As

an example we would not recommend placing an inlet valve just above people with sedentary work

because the inlet air in some cases would be experienced as a draught.

Granulate

Duct

Loft insulationmaterial