5 - 4

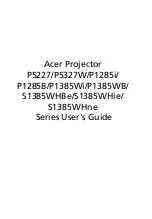

BA02基板

BS3×6

Znc

2

BA02 board

BS3×6

ZnC

2

5.2.2 Replacement of the BA02 board

Replacement part: 33155-BA02

1. Remove the top and front cover ASSYs. (See 5.1.)

2. Disconnect the connector from J7 on the BA01 board.

3. Unscrew BS3 × 6

ZnC

(n=2) to replace the

BA02 board with a new one.

4. Assemble the removed parts in reverse order.

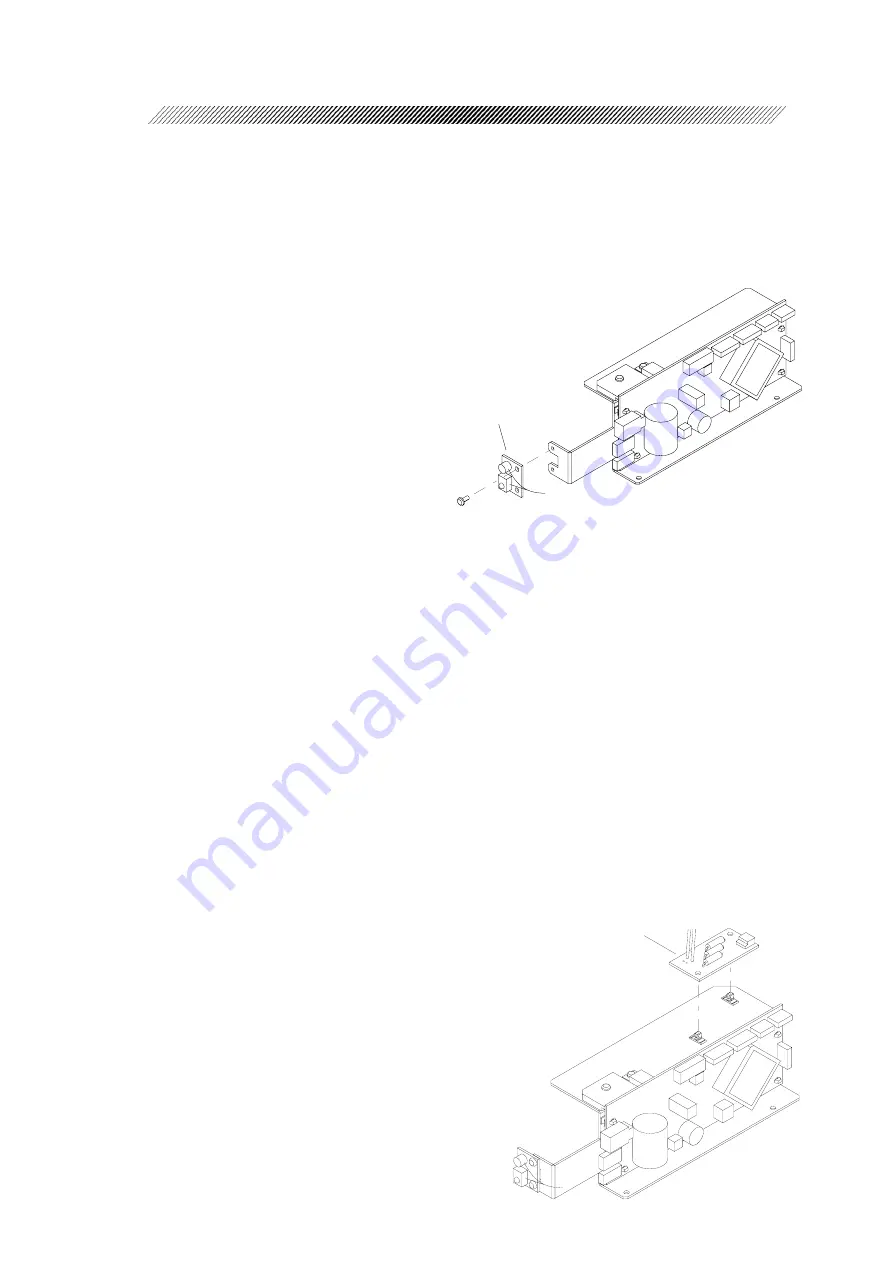

5.2.3 Replacement of the BA14 board

Replacement part: 33155-BA14

[NOTE]

Once the lamp goes on, the device on the BA14 board becomes hot. Do not conduct

work until the device cool down.

1. Remove the top and front cover ASSYs. (See 5.1.)

2. Disconnect J2 connector and EA14 cable connector on the BA01 board.

3. Remove the BA14 board while holding the tops of the two spacers with long-nose pliers

and replace with new one.

* Push the new board into the spacers properly.

4. Assemble the removed parts in reverse order.

BA14基板

BA14 board

Summary of Contents for CP-690

Page 6: ...1 2...

Page 8: ...2 2...

Page 44: ...5 22...

Page 56: ...7 2 EA01...

Page 57: ...7 3 EA02...

Page 60: ...7 6...

Page 70: ...9 2...