7

Maintenance and service guide - LSN-FLSN ZONE

2 - Ex ec

5724 en - 2020.02 / c

3.2 - Checking the insulation

Throughout the period required for checking insulation, ensure

that there is no explosive atmosphere present.

Before operating the motor we

recommend checking the insulation between

phases and earth and between phases.

Motors are factory-fitted with preventative advice labels

which must kept legible.

Before commissioning remove condensation (see §10.4

- ROUTINE MAINTENANCE)

This check is essential if the motor has been stored for longer

than 6 months or if it has been kept in a damp atmosphere.

This measurement must be carried out using a megohmmeter

at 500 volts DC (do not use a magneto-electric system).

It is better to carry out an initial test at 30 or 50 volts and if the

insulation is greater than 1 megohm, carry out a second test at

500 volts DC for 60 seconds. The insulation value must be at

least 10 megohms in cold state.

If this value cannot be achieved, or routinely if the motor might

have been splashed with water or salt spray, or kept for a long

period in a very humid place, or if it is covered with condensation,

it is recommended that the stator be dried for 24 hours in an

oven at a temperature of 110 °C to 120 °C.

If it is not possible to dry the motor in an oven:

- supply the motor, with the rotor immobilised, with a

three-phase AC voltage which is 10% below the rated voltage,

for 12 hours (use an induction regulator or a step-down

transformer with adjustable points).

- or supply it with DC supply with the 3 phases in series, with a

voltage value of 1 to 2% of the rated voltage (use a separate

excitation DC generator or batteries for motors of less than 22 kW).

- NB: The AC current must be monitored using a clamp-on

ammeter, DC using a shunt ammeter. This current must not

exceed 60 % of the rated current.

It is recommended that a thermometer be fitted to the motor

frame: if the temperature exceeds 70 °C, reduce the indicated

voltage or current by 5 % of the original value for every 10 °C

difference.

While it is drying, all the motor orifices must be open (terminal

box, drain holes). Before starting replace all plugs so that the

motor exhibits the plated degree of protection. Clean the

orifices and plugs before refitting them.

Warning! Since the high voltage test was carried

out at the factory before dispatch. If it needs to be

repeated, this should be performed at half the standard

voltage, i.e.: 1/2 (2U+1000V). Check that the capacitive

effect resulting from the high voltage test is eliminated

before connecting the terminals to ground.

For all motors before commissioning:

- remove the dust from the entire machine

- rotate the motor at no load (no mechanical load) for 2 to

5 minutes, checking that there is no abnormal noise. If

there is any abnormal noise, see section 10.

4 - INSTALLATION

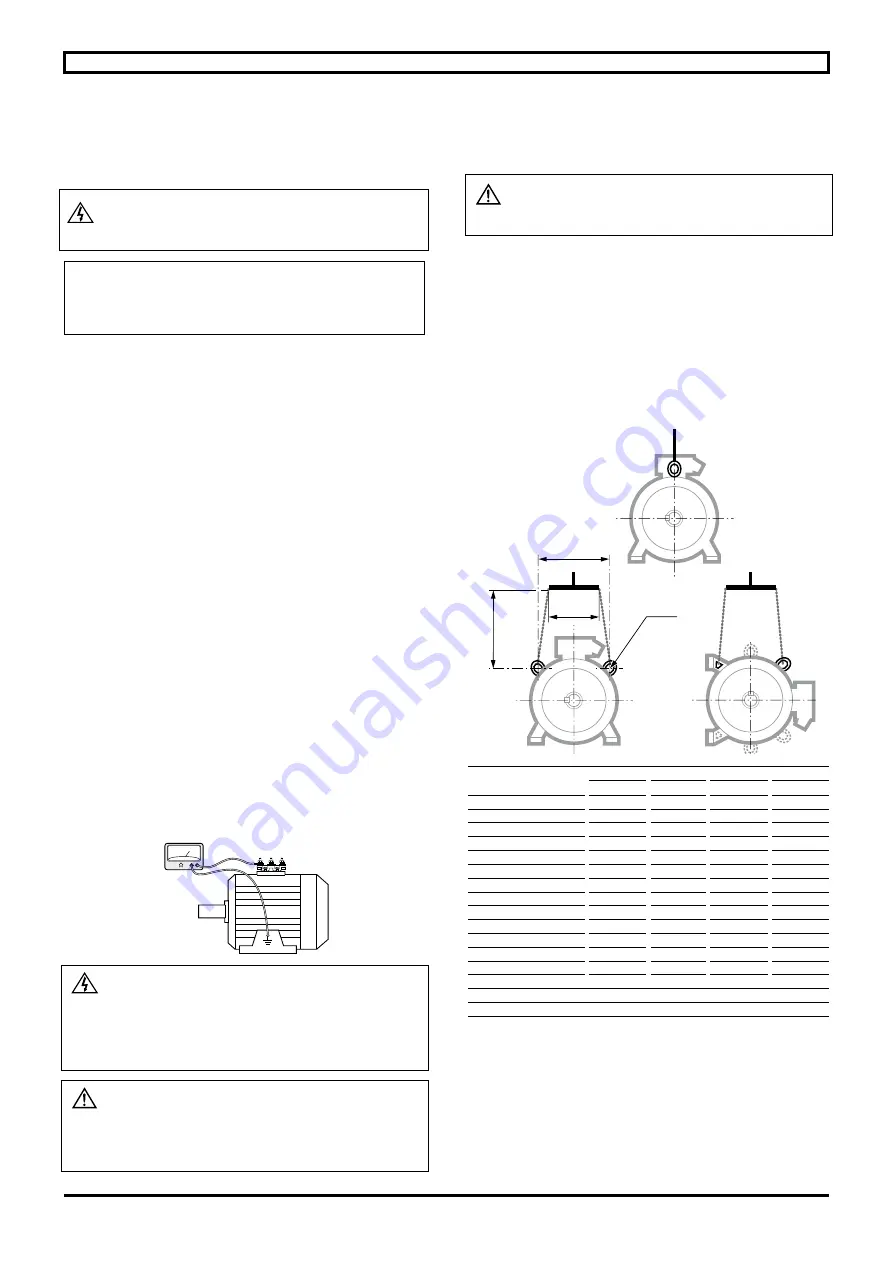

4.1 - Position of the lifting rings

The lifting rings are provided for lifting

only the motor. They must not be used to lift the

machine after the motor has been fitted to it.

Labour regulations stipulate that all loads over 25 kg must be

fitted with lifting devices to facilitate handling.

The overall mass of motors can vary according to their power,

their mounting position and whether the motors are fitted with

optional equipment. The actual weight of each Nidec Leroy-

Somer motor is indicated on its nameplate. The positions of the

lifting rings and the minimum dimensions of the loading bars

are given below in order to help with preparation for handling

the motors. If these precautions are not followed, there is a risk

of warping or crushing some equipment such as the terminal

box, protective cover or drip cover.

Type

Horizontal position

A

e min

h min

Øt

100

120

200

150

9

112

120

200

150

9

132

160

200

150

9

160

200

160

110

14

180 MR

200

160

110

14

180 L

200

260

150

14

200

270

260

165

14

225 ST/MT

270

260

150

14

225 M

360

265

200

30

250

360

380

200

30

280

360

380

500

30

315 S

310

380

500

17

315 M/L

360

380

500

23

355

310

380

500

23

355 LK - 400

735

710

500

30

400 LK - 450

730

710

500

30

M

e

A

h

2 x Øt

• Horizontal position

INSTALLATION AND MAINTENANCE – LSN-FLSN ZONE 2 – Ex ec