4

To maintain the guaranteed level of safety of the TCB sensitive edge,

regular maintenance must be performed at max. 6 month intervals.

1. To prevent inadvertent start-up of moving parts, disconnect the

automation from the electrical mains

2. Check all sensitive edge parts for wear with special attention to

erosion or rust on the aluminium profile and relative fixtures.

3. Check the rubber profile for wear; if cracked or perforated parts

are found, the entire edge must be replaced.

4. Reconnect the unit to the mains and perform all tests and checks

as envisaged in the section "Testing"

4) Maintenance and disposal

10. To prolong the lifetime of the sensitive edge, the unit should be

bled to remove any residual condensate.

In the case of vertical installations, bleed only from the lower cap;

in the case of horizontal installations, bleed from both outlets.

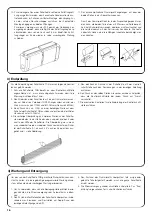

For this operation, the stem must be removed as shown in fig-

ure and the tip of the bleed cone must be cut to obtain a 2-3 mm

hole. On completion, push the bleed cone back into its original

position.

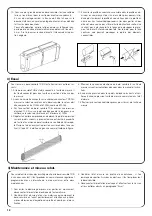

11. Insert the sensitive rubber edge into the aluminium profile start-

ing from one end.

To facilitate insertion of the rubber edge into the aluminium pro-

file, spray both parts lightly with soap and water; do not use

lubricant oil as this does not dry and could cause the edge to slip

after installation. Never pull the edge to slide it through the pro-

file as this can damage conductive elements.

To test the TCB sensitive edge, the following checks are required:

1. If the TCB sensitive edge is already connected to the detection

unit, disconnect it to ensure that the unit does not alter measure-

ments.

2. Connect an Ohmmeter to the wire of the TCS250 connector and

measure the resistance of the sensitive edge; the value should be

between 7700

Ω

and 8700

Ω

(nominal 8200

Ω

).

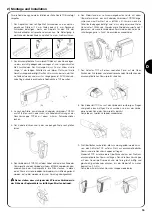

3. On the vertical axis of the TCB sensitive edge exert a pressure of

approx. 100N at any point of its length and check that the resis-

tance value is below 1000

Ω

.

4. Repeat the above check by applying pressure as above in the

three following points: near each end and mid-way along the sen-

sitive edge. Repeat the check several times, applying pressure

both on the vertical axis (0°) and 45° to the right or left as shown

in the figure.

5. Make the electrical connections of the sensitive edge to the

detection unit as specified in the relative instruction manual.

6. Apply pressure at the same points specified above and check

each time that the detection unit changes to alarm status.

7. Make all envisaged checks required for detection unit testing.

3) Testing