ENGLISH –

15

&

&

INSTRUCTIONS AND WARNINGS FOR THE USER

Before using the automation for the first time, ask the installer to

explain the origin of any residual risks and take a few minutes to

read this instruction manual and warnings for the user given to you

by the installer. Store the manual for future reference and hand it to

the new owner when transferring the automation.

a

WARNING!

Your automation is a machine that faithfully exe-

cutes commands imparted by the user. Negligence

and improper use may lead to dangerous situations:

–

do not manoeuvre the gate if there are people, animals or

objects within its range of operation

–

it is strictly forbidden to touch parts of the automation

while it is moving.

a

IT IS STRICTLY FORBIDDEN to transit while the au-

tomation is closing! Transit is allowed only if the au-

tomation is fully open and stationary.

a

CHILDREN

An automation system guarantees a high degree

of safety. With its detection systems, it can control

and guarantee the gate’s movement in the presence

of people or objects. It is nonetheless advisable to

forbid children from playing near the automation

and not to leave remote controls near them to pre-

vent any unwanted activation of the system. The

automation is not a toy!

The product is not intended for use by persons, in-

cluding children, with limited physical, sensory or

mental capacities, or who lack experience or knowl-

edge, unless supervised or trained in the use of the

product by a person responsible for their safety.

Anomalies:

if the automation shows any signs of anomalous be-

haviour, disconnect the power supply to the system and manually

unlock the motor (see instructions at the end of the chapter) to

manoeuvre the automation manually. Do not attempt any repairs

personally, but contact your trusted installer.

Failure or lack of power supply:

while waiting for the installer

to intervene or the electricity to be restored, if the system is not

equipped with back-up batteries, the automation can nonetheless

be used by manually unlocking the motor (see the instructions at

the end of the chapter) and moving the automation manually.

l

Do not modify the system: the responsibility lies on

your installer.

Testing, periodic maintenance and any repairs must be document-

ed by the person performing the operations and the relative docu-

ments must be kept by the owner of the installation.

m

Before carrying out any maintenance operations,

the user of the automation must manually unlock

the motor to prevent anyone from accidentally trig-

gering the automation’s movement (see the instruc-

tions at the end of the chapter).

Maintenance:

in order to ensure constant levels of safety and the

longest useful life for the automation, routine maintenance must be

carried out (at least every 6 months).

l

Only qualified personnel is authorised to carry out

checks, maintenance operations and repairs.

Disposal:

at the end of its useful life, the automation must be dis-

mantled by qualified personnel and the materials must be recycled

or disposed of in compliance with the local regulations in force.

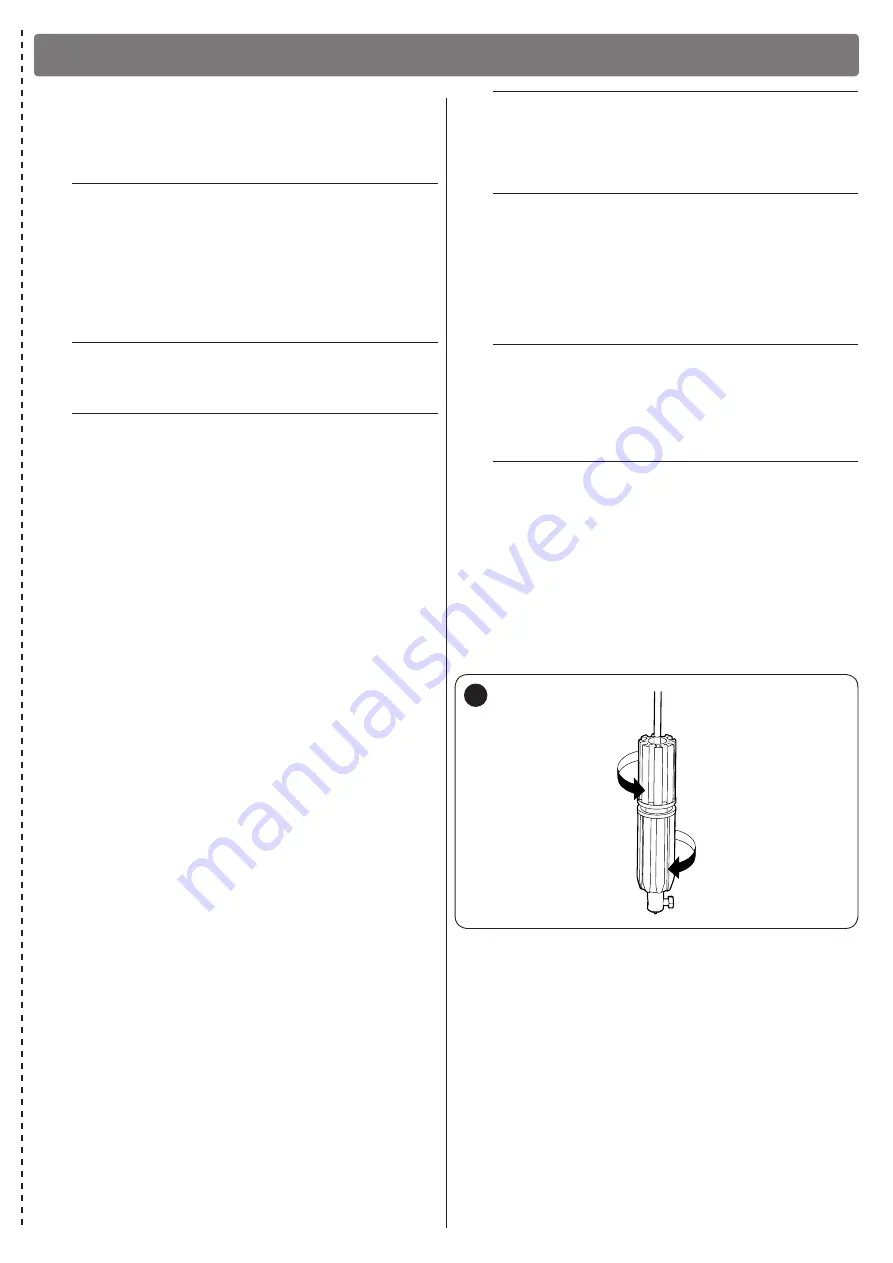

Unlocking and manual movement

a

The device can only be unlocked once the automa-

tion is stationary.

Gearmotors equipped with an electric brake have a mechanical

unlocking system that allows for opening and closing the shutter

manually.

These manual operations should only be performed in case of a

power outage, malfunctions or during the installation phases.

To unlock the device:

1.

loosen the lower part of the knob anti-clockwise until you

can

2.

at this point, the shutter can be moved manually to the de-

sired position.

21

To lock the device, turn the knob clockwise all the way.