EN

English –

15

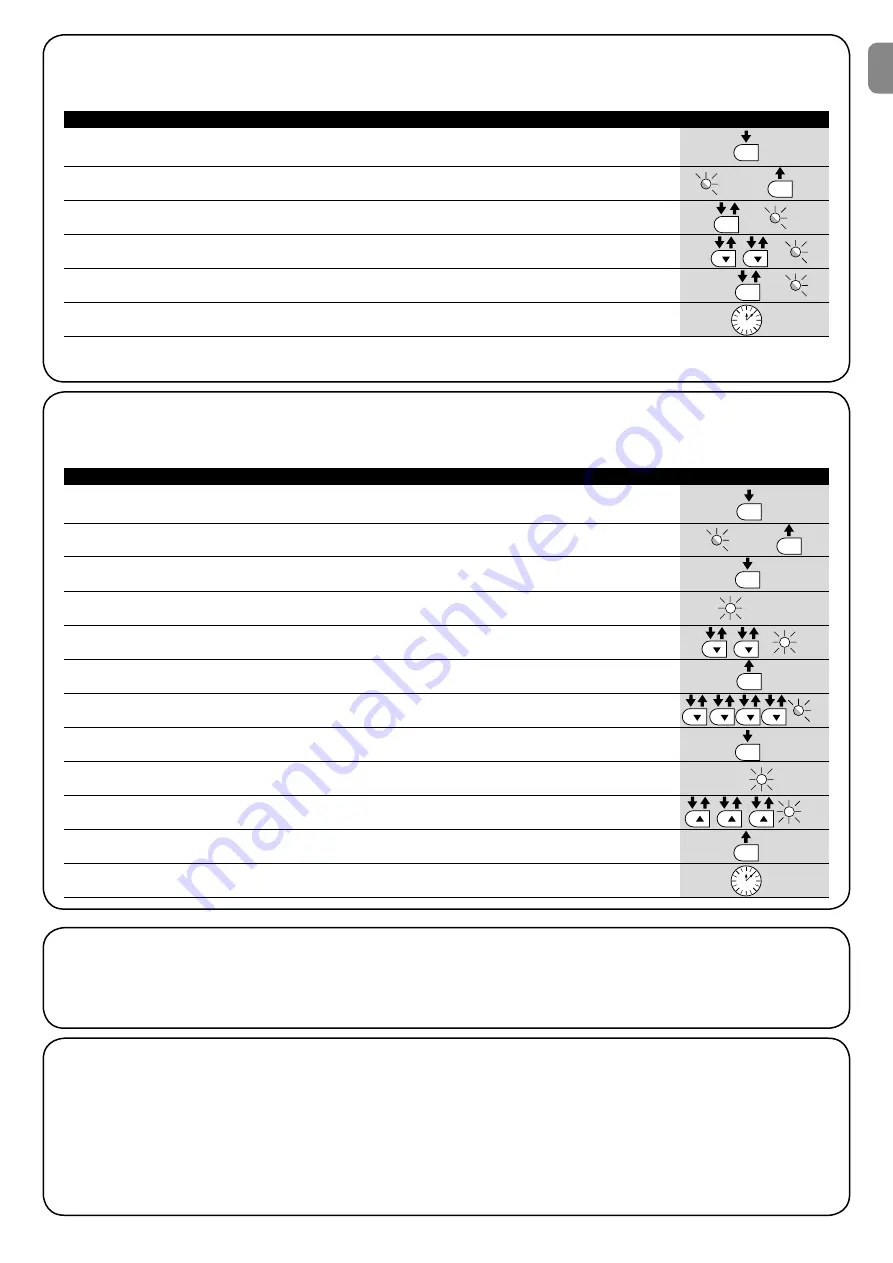

7.2.6) Level two programming example (adjustable parameters)

The sequence to follow in order to change the factory settings of the parameters increasing the “Pause Time” to 60 seconds (input on L1

and level on L5) and reducing the “Motor Force” for light gates (input on L5 and level on L2) have been included as examples

1.

Press the key

[Set]

and hold it down (approx. 3 s)

3s

2.

Release the

[Set]

key when L1 LED starts flashing

L1

3.

Press the key

[Set]

and hold it down during step 4 and 5

4.

Wait approx. 3 seconds until LED L3, representing the current level

of the “Pause Time” will light up

L3

3s

5.

Press the

[

t

]

key twice to move the LED which is lit to LED L5,

which represents the new “Pause Time” value

L5

6.

Release the key

[Set]

7.

Press the

[

t

]

key four times to move the flashing LED to LED L5

L5

8.

Press the key

[Set]

; and hold it down during step 9 and 10

9.

Wait approx. 3 seconds until LED L5, representing the current

level of the “Motor Force” will light up

3s

L5

10.

Press the

[

s

]

key three times to move the LED which is lit to LED L2,

which represents the new “Motor Force” value

L2

11.

Release the key

[Set]

12.

Wait 10 seconds before leaving the programme to allow the maximum time to lapse.

10s

Table 10: Level two programming example

Example

SET

SET

SET

SET

SET

SET

7.3) Adding or removing devices

Devices can be added to or removed from the ROBUS automation

system at any time. In particular, various devices types can be con-

nected to “BLUEBUS” and “STOP” input as explained in the follow-

ing paragraphs.

After you have added or removed any devices, the automa-

tion system must go through the recognition process again

according to the directions contained in paragraph 7.3.6

“Recognition of other devices”.

7.3.1) BLUEBUS

BLUEBUS technology allows you to connect compatible devices

using only two wires which carry both the power supply and the

communication signals. All the devices are connected in parallel on

the 2 wires of the BLUEBUS itself. It is not necessary to observe any

polarity; each device is individually recognized because a univocal

address is assigned to it during the installation. Photocells, safety

devices, control keys, signalling lights etc. can be connected to

BLUEBUS. The ROBUS control unit recognizes all the connected

devices individually through a suitable recognition process, and can

detect all the possible abnormalities with absolute precision. For this

reason, each time a device connected to BLUEBUS is added or

removed the control unit must go through the recognition process;

see paragraph 7.3.6 “Recognition of Other Devices”.

7.2.5) Level one programming example (ON-OFF functions)

The sequence to follow in order to change the factory settings of the functions for activating “Automatic Closing” (L1) and “Always close”

(L3) have been included as examples.

1.

Press the key

[Set]

and hold it down (approx. 3 s)

3s

2.

Release the

[Set]

key when L1 LED starts flashing

L1

3.

Press the

[Set]

key once to change the state of the function associated with L1

Automatic Closing). LED L1 will now flash with long flashes.

L1

4.

Press the

[

t

]

key twice to move the flashing LED to LED L3

L3

5.

Press the

[Set]

key once to change the state of the function associated with L3

(Always Close). LED L3 will now flash with long flashes.

L3

6.

Wait 10 seconds before leaving the programme to allow the maximum time to lapse.

10s

Once these operations have been completed, LEDs L1 and L3 must remain on to indicate that the “Automatic Closing” and the “Always

Close” functions are active.

Table 9: Level one programming example

Example

SET

SET

SET

SET

Summary of Contents for ROBUS RB1000

Page 28: ......