4

– ENGLISH

INSTALLATION

3

3

INSTALLATION

3.1 PRE-INSTALLATION CHECKS

Before proceeding with the product’s installation, it is necessary to:

–

check the integrity of the supply

–

check that all the materials are in good working order and suited

to the intended use

–

check that all operating conditions comply with that specified in

the “

–

check that the chosen installation location is compatible with the

product’s overall dimensions (see “

Figure

–

check that the surface chosen for installing the product is solid

and can ensure stable attachment

–

make sure that the installation area is not subject to flooding;

if necessary, the product must be installed appropriately raised

above ground level

–

check that the space around the product allows safe and easy

access

–

check that all electrical cables to be used belong to the type

”

–

check that the automation has mechanical stops in both the

opening and closing phases.

3.2 PRODUCT USAGE LIMITS

The product can be used exclusively for controlling TTN3724HSC

electromechanical actuators and in accordance with the

corresponding usage limits.

3.3 PRODUCT IDENTIFICATION AND OVERALL

DIMENSIONS

The overall dimensions and label (A) that allow for identifying the

product are shown in “

Figure

”.

232 mm

310 mm

122 mm

A

2

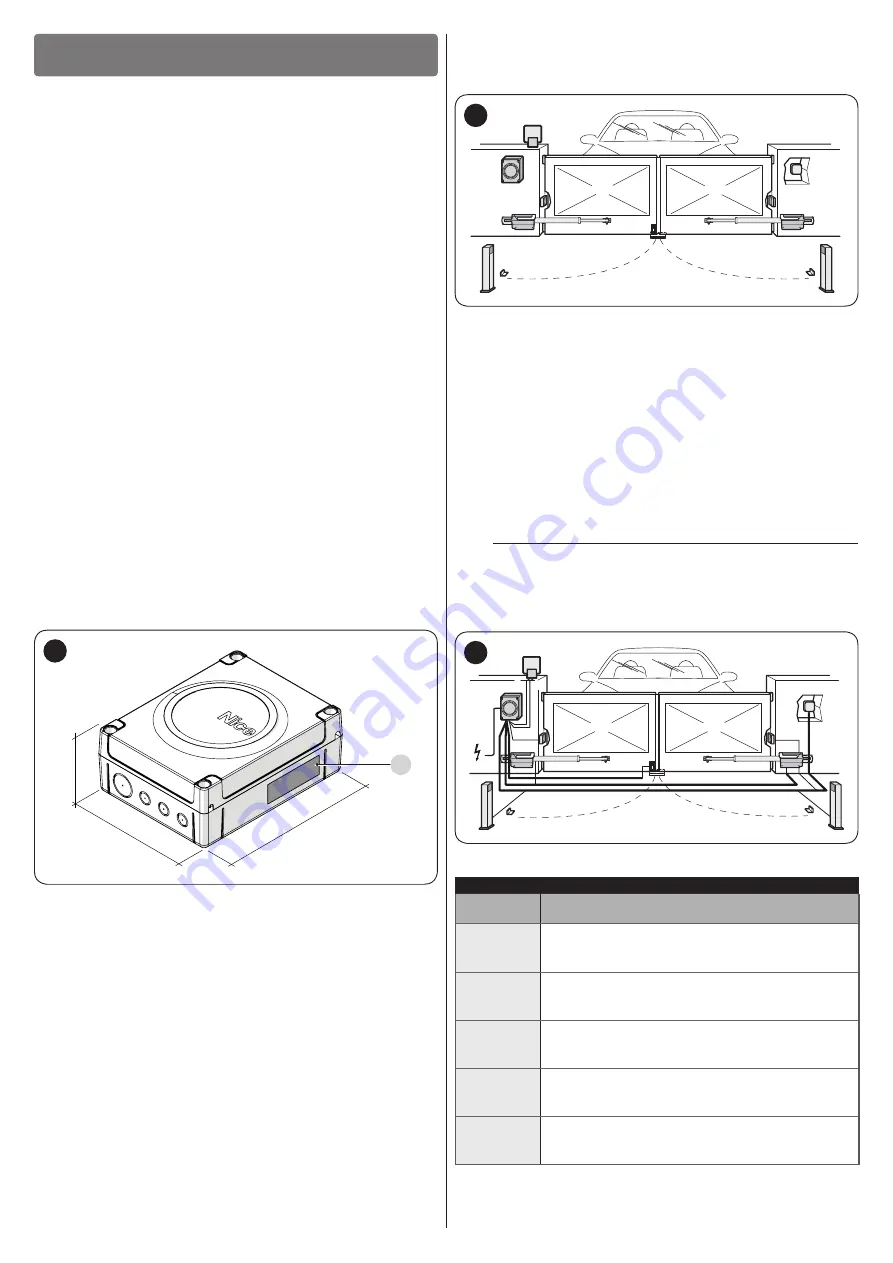

3.4 TYPICAL INSTALLATION

“

Figure

” shows an example of an automation system constructed

using

Nice

components.

D

D

G

G

B

H

B

E

A

F

F

C

I

3

A

Control unit

B

Gearmotor

C

Warning light

D

Photocell

E

Digital keypad - Transponder reader - Key selector

F

Photocell column

G

Mechanical stops for the open position

H

Mechanical stop at closed position

I

Electric lock

These above-mentioned components are positioned according

to a typical standard layout. Using the layout in “

Figure

” as

a reference, define the approximate position in which each

component of the system will be installed.

a

Before proceeding with the installation, prepare

the required electrical cables by referring to

“

Figure

” chapter.

b c

a

d

g

f-h

d

d

e

d

4

Table 1

TECHNICAL SPECIFICATIONS OF ELECTRICAL CABLES

Identification

no.

Cable characteristics

a

CONTROL UNIT POWER SUPPLY cable

1 cable 3 x 1.5 mm

2

Maximum length 30 m [

note 1

]

b

WARNING LIGHT cable

1 cable 2 x 0.5 mm

2

Maximum length 20 m

c

ANTENNA cable

1 x RG58-type shielded cable

Maximum length 20 m; recommended < 5 m

d

BLUEBUS DEVICES cable

1 cable 2 x 0.5 mm

2

Maximum length 20 m [

note 2

]

e

KEY SELECTOR cable

2 cables 2 x 0.5 mm

2

Maximum length 50 m [

note 3

]

Summary of Contents for MC824HHS

Page 1: ...Nice MC824HHS Control unit EN Instructions and warnings for installation and use...

Page 24: ...24 ENGLISH NOTES...

Page 26: ...26 ENGLISH NOTES...

Page 27: ...ENGLISH 27 NOTES...