10

– English

6

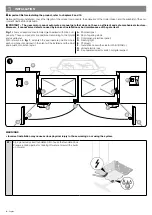

OPTIONAL ACCESSORIES

The following optional accessories are available:

ACCESSORI

PLA10 electric lock 12 V

vertical

PLA11 electric lock 12 V horizontal

BMA1 360° opening device

BMA3 Lever-operated release mechanism

Refer to the user manuals of the various individual products.

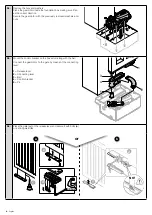

7

MAINTENANCE

To ensure that the level of safety of the installation is maintained and that the system remains reliable and operational, it must be serviced regularly

in observance of the safety regulations given in this manual and established legislation.

The gearmotor must be serviced no later than 6 months after commissioning.

01.

Disconnect all power supplies

02.

Check for any deterioration in automation system components, paying special attention to erosion or oxidation of its structural parts

Replace any parts which are below the required standard

03.

Check that all screw fasteners are fully tightened down

04.

Check the wear of all moving parts and replace any worn components

05.

Connect the power supplies up again, and run all the tests and checks described in Chapter 4

For the other equipment in the system, refer to its user manuals.

8

DISPOSAL OF THE PRODUCT

This product is an integral part of the automation and must be scrapped with it.

Similarly to the installation operations, also at the end of this product’s working life the dismantling and scrapping operations must be performed

by qualified personnel.

This product is made up of different types of material, some of which can be recycled while others must be disposed of. Seek information on the

recycling and disposal systems envisaged by the local regulations in your area for this product category.

CAUTION

! – some parts of the product may contain polluting or hazardous substances which, if disposed of into the environment,

constitute serious environmental and health risks.

As indicated by the symbol, the product may not be disposed of as domestic waste. Sort the materials for disposal, according

to the methods envisaged by current legislation in your area, or return the product to the retailer when purchasing an equivalent

product.

CAUTION

! – Local legislation may envisage serious fines in the event of abusive disposal of this product.

Summary of Contents for BFAB5024

Page 2: ...2 English...

Page 16: ......