6 - SETTING WORKING TIME OF MOTORS

Default: no time set

NOTE:

Before carrying out this procedure programme a remote control (see paragraph 5)

Also check that the motor stops when it gets to the limit and the letter “L” appears on the display (the limit is detected if

there is a mechanical stop or where there is a built-in limit switch).

If that does not occur, adjust the movement threshold with the VR1 trimmer “Sens.” (the trimmer adjusted full scale to “-”

disables the movement threshold).

To obtain non-manual operation via radio set the operation to automatic, Venetian or Open-Stop-Close (see paragraph

3.1).

PROCEDURE

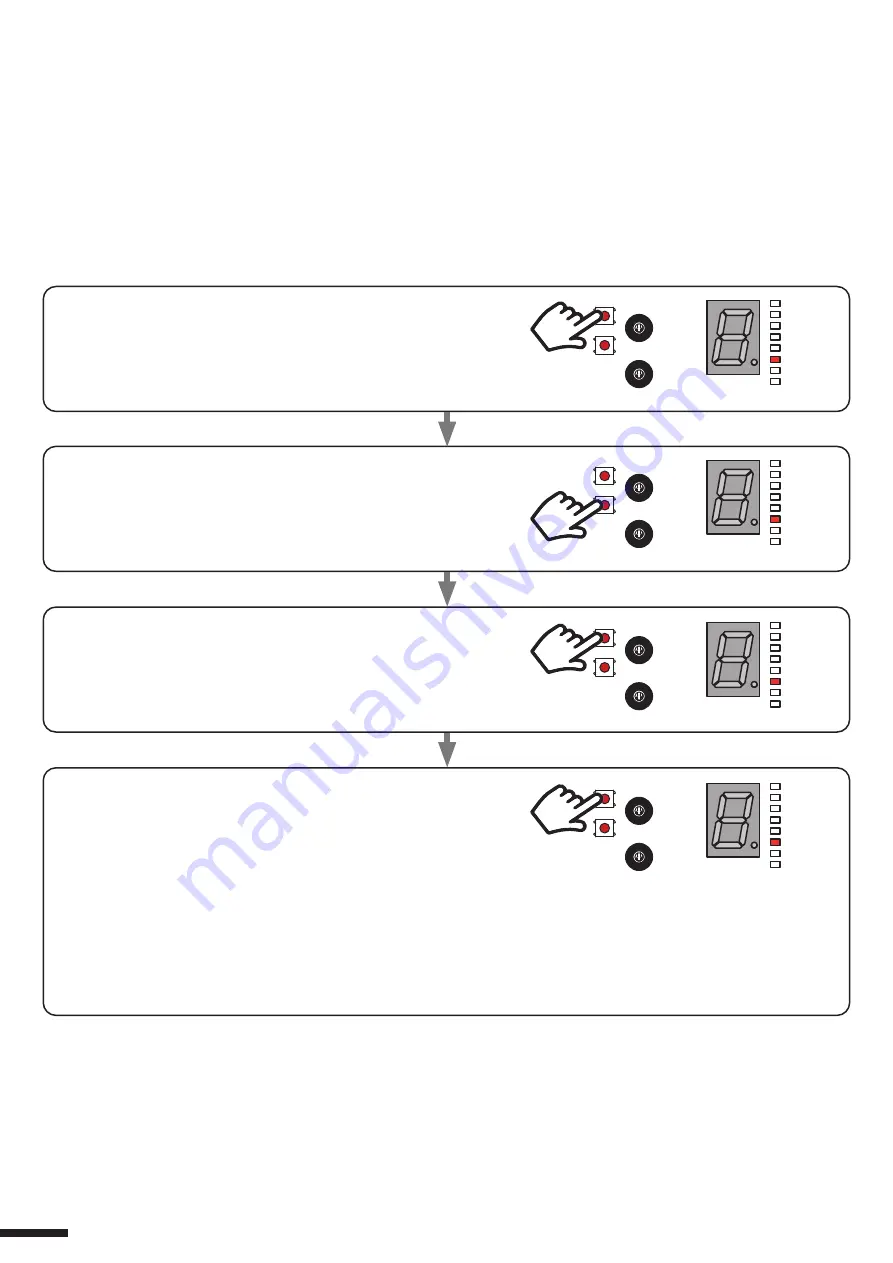

STEP 1

Keep pressing and releasing the SEL key until the

«T.MOT.» LED comes on.

STEP 2

Press and release the SET button to confirm. The LED on

the display flashes.

STEP 3

By pressing and releasing the SEL key you can select value

"0" on the display

STEP 4

Press and release the SET button to start automatic programming.

The control unit will make a closing movement followed by opening

and closing cycles at the end of which the maneuver times will be

programmed.

ATTENTION: if the first movement is opening instead of closing, press

the SET button to interrupt the programming of the run and invert the

phases of the motor. Then repeat the procedure.

8

SOLE

NEVE

TEMP.

PIOGGIA

VENTO

T.MOT.

CODE

MOT.TYPE

SEL

Sens.

Rit. Neve

SET

SOLE

NEVE

TEMP.

PIOGGIA

VENTO

T.MOT.

CODE

MOT.TYPE

SEL

Sens.

Rit. Neve

SET

SOLE

NEVE

TEMP.

PIOGGIA

VENTO

T.MOT.

CODE

MOT.TYPE

SEL

Sens.

Rit. Neve

SET

SOLE

NEVE

TEMP.

PIOGGIA

VENTO

T.MOT.

CODE

MOT.TYPE

SEL

Sens.

Rit. Neve

SET

Summary of Contents for PRG-M24

Page 15: ...15...