8

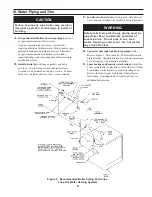

Figure 6: Pilot and Gas Piping, Continuous

Ignition (Standing Pilot)

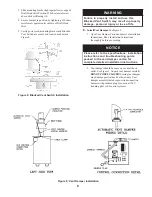

Figure 7: Pilot and Gas Piping, Intermittent

Ignition (EI)

V. Venting

A.

Install

vent system

in accordance with local building

codes; or local authority having jurisdiction; or

National Fuel Gas Code

, ANSI Z223.1/NFPA 54, Part 7,

Venting of Equipment. Install any of the following for

this Classic CG-A Series Category I, draft hood

equipped appliance:

1. Type B or Type L gas vent. Install in accordance

with listing and manufacturer's instructions.

2. Masonry or metal chimney. Build and install in

accordance with local building codes; or local

authority having jurisdiction; or

Standard for

Chimneys, Fireplaces, Vents, and Solid Fuel

Burning Appliances

, ANSI/NFPA 211.

Masonry chimney must be lined with approved clay

flue lining or listed chimney lining system except as

provided in ANSI Z223.1/NFPA 54, Paragraph

7.5.4(a):

Exception: Where permitted by the

authority having jurisdiction, existing chimneys

shall be permitted to have their use continued when

an appliance is replaced by an appliance of similar

type, input rating, and efficiency.

3. Single wall metal vent. Allowed by ANSI Z223.1/

NFPA 54 under very restrictive conditions.

B.

Inspect chimney

and remove any obstructions or

restrictions. Clean chimney if previously used for solid

or liquid fuel-burning appliances or fireplaces.

R

E

G

N

A

D

g

n

i

l

l

a

t

s

n

i

e

r

o

f

e

b

y

e

n

m

i

h

c

g

n

i

t

s

i

x

e

t

c

e

p

s

n

I

d

e

t

a

r

o

f

r

e

p

e

c

a

l

p

e

r

r

o

n

a

e

l

c

o

t

e

r

u

l

i

a

F

.

r

e

l

i

o

b

r

o

y

r

u

j

n

i

e

r

e

v

e

s

e

s

u

a

c

l

l

i

w

g

n

i

n

i

l

e

l

i

t

r

o

e

p

i

p

.

h

t

a

e

d

C.

Install Draft Hood

without modification on outlet of flue

collector. See Figure 1. Secure with sheet metal screws.

G

N

I

N

R

A

W

y

n

a

e

c

a

l

p

r

o

d

o

o

h

t

f

a

r

d

r

e

l

i

o

b

r

e

t

l

a

t

o

n

o

D

e

h

t

n

i

r

e

p

m

a

d

d

e

v

o

r

p

p

a

-

n

o

n

r

o

n

o

i

t

c

u

r

t

s

b

o

e

g

a

l

l

i

p

s

s

a

g

e

u

l

F

.

m

e

t

s

y

s

t

n

e

v

r

o

g

n

i

h

c

e

e

r

b

e

m

o

c

e

b

l

l

i

w

n

o

i

t

a

c

i

f

i

t

r

e

c

L

T

E

.

r

u

c

c

o

n

a

c

.

d

i

o

v

D.

Install Blocked Vent Switch.

The Blocked Vent Switch

Assembly shipped taped to top of boiler includes power

cord and switch attached to mounting bracket.

1. Untape Blocked Vent Switch Assembly from top of

boiler. Uncoil power cord.

2. Position mounting bracket onto lower edge of Draft

Hood skirt. Locate center tooth (with #10 sheet

metal screw) on outside and other two teeth inside

Draft Hood skirt. See Figure 8.

Summary of Contents for CG-A 30

Page 16: ...16 Figure 15 Operating Instructions ...

Page 17: ...17 Figure 16 Lighting Instructions ...

Page 20: ...20 ...

Page 21: ...21 ...