- 34 -

www.NewLeader.com

(800) 363-1771

316536-AA-A

XT3 TYPE III

Header

Hydraulic Hose

Hose assemblies in operation should be inspected frequently for leakage, kinking, abrasion, corrosion or

other signs of wear or damage� Worn or damaged hose assemblies should be replaced immediately�

WARNING

Testing should be conducted in approved test stands with adequate guards to protect the

operator�

Clean

Clean assembly by blowing out with clean compressed air� Assemblies may

be rinsed out with mineral spirits if the tube stock is compatible with oil,

otherwise hot water at 150°F (65�55° C) maximum may be used�

Inspect

Examine hose assembly internally for cut or bulged tube, obstructions, and

cleanliness. For segment style fittings, be sure that the hose butts up against

the nipple shoulder; band and retaining ring are properly set and tight, and

segments are properly spaced� Check for proper gap between nut and

socket or hex and socket� Nuts should swivel freely� Check the layline of the

hose to be sure the assembly is not twisted� Cap the ends of the hose with

plastic covers to keep clean�

Test

The hose assembly should be hydrostatically tested at twice the

recommended working pressure of the hose�

Test pressure should be held for not more than one minute and not less than

30 seconds� When test pressure is reached, visually inspect hose assembly

for: 1. Any leaks or signs of weakness. 2. Any movement of the hose fitting

in relation to the hose� Any of these defects are cause for rejection�

Storage and Handling

Hose should be stored in a dark, dry atmosphere away from electrical equipment, and the temperature

should not exceed 90° F (32° C)�

Lubrication & Maintenance

Conveyor Chain

WARNING

Stay out of the hopper body� If it’s necessary to enter the hopper, return to the shop, empty

body, turn off all power, set vehicle brakes, lock engine starting switch and remove keys

before entering� Tag all controls to prohibit operation� Tags should be placed, and later

removed, only by person working in the body�

Hose down unit and remove any material build-up on sprockets and under chain�

NOTICE!

The conveyor will move away from the bottom panel if material accumulates under the conveyor or

on the sprockets� The more material that accumulates, the closer the chain will come to the chain

shields� If the conveyor should catch a chain shield, it could permanently damage the conveyor, the

chain shields or the unit� Do not remove material while conveyor or spinner is running!

Summary of Contents for Hi-Way XT3 TYPE III

Page 6: ...Insert Current HI WAY Warranty Warranty...

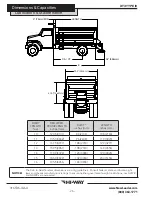

Page 44: ...44 www NewLeader com 800 363 1771 316536 AA A XT3 TYPE III Cradle Body...

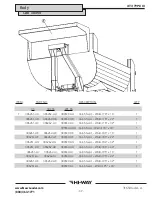

Page 50: ...50 www NewLeader com 800 363 1771 316536 AA A XT3 TYPE III Side Boards Bolt In Body...

Page 55: ...55 XT3 TYPE III www NewLeader com 800 363 1771 316536 AA A Body Lubrication Cont Lubrication...

Page 58: ...58 www NewLeader com 800 363 1771 316536 AA A XT3 TYPE III Tailgate w Feedgate Tailgate...

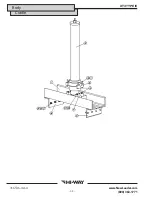

Page 64: ...64 www NewLeader com 800 363 1771 316536 AA A XT3 TYPE III Domed Screens...

Page 72: ...72 www NewLeader com 800 363 1771 316536 AA A XT3 TYPE III Chain Shield 4 BOC Conveyor...

Page 74: ...74 www NewLeader com 800 363 1771 316536 AA A XT3 TYPE III Chain Shield 3 Bar Chain Conveyor...

Page 92: ...92 www NewLeader com 800 363 1771 316536 AA A XT3 TYPE III Sand Bagger Accessories...