INTRODUCTION

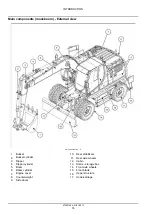

Upper structure main components - internal view

SMIL12WEX0175GB

3

1.

Slewing bearing

11.

Radiator assy

2.

Refueling pump box

12.

Con dryer (conditioning air system)

3.

Protection handrails

13.

Batteries

4.

Main valve

14.

Air filter

5.

Fuel tank

15.

Pilot control assy

6.

Hydraulic oil tank

16.

Diesel engine

7.

Hydraulic pumps

17.

Cabin installation with ROPS (Rolling Over Protection

System)

8.

Muffler

18.

Slewing gearbox

9.

Counterweight

19.

Operator’s seat

10.

Rear view camera

47500165A 31/01/2013

17

Summary of Contents for WE150B

Page 2: ...SERVICE MANUAL WE150B 47500165A 31 01 2013 EN Find manuals at https best manuals com ...

Page 7: ...47500165A 31 01 2013 Find manuals at https best manuals com ...

Page 8: ...INTRODUCTION 47500165A 31 01 2013 1 Find manuals at https best manuals com ...

Page 50: ...SERVICE MANUAL Engine WE_B 47500165A 31 01 2013 10 ...

Page 51: ...This as a preview PDF file from best manuals com Download full PDF manual at best manuals com ...