Summary of Contents for LB110

Page 1: ...Backhoe Loaders LB75 B LB90 LB110 LB115 B SERVICE MANUAL II I EWHOLLAI CONSTRUCTION ...

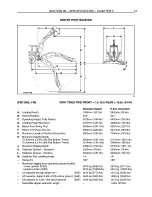

Page 36: ...10 SECTION 00 SPECIF CATIONS CHAPTER 2 NOTES ...

Page 44: ...18 SECTION 00 SPECIF CATIONS CHAPTER 2 NOTES ...

Page 51: ...This as a preview PDF file from best manuals com Download full PDF manual at best manuals com ...