SECTION 00 - SAFETY RULES

9

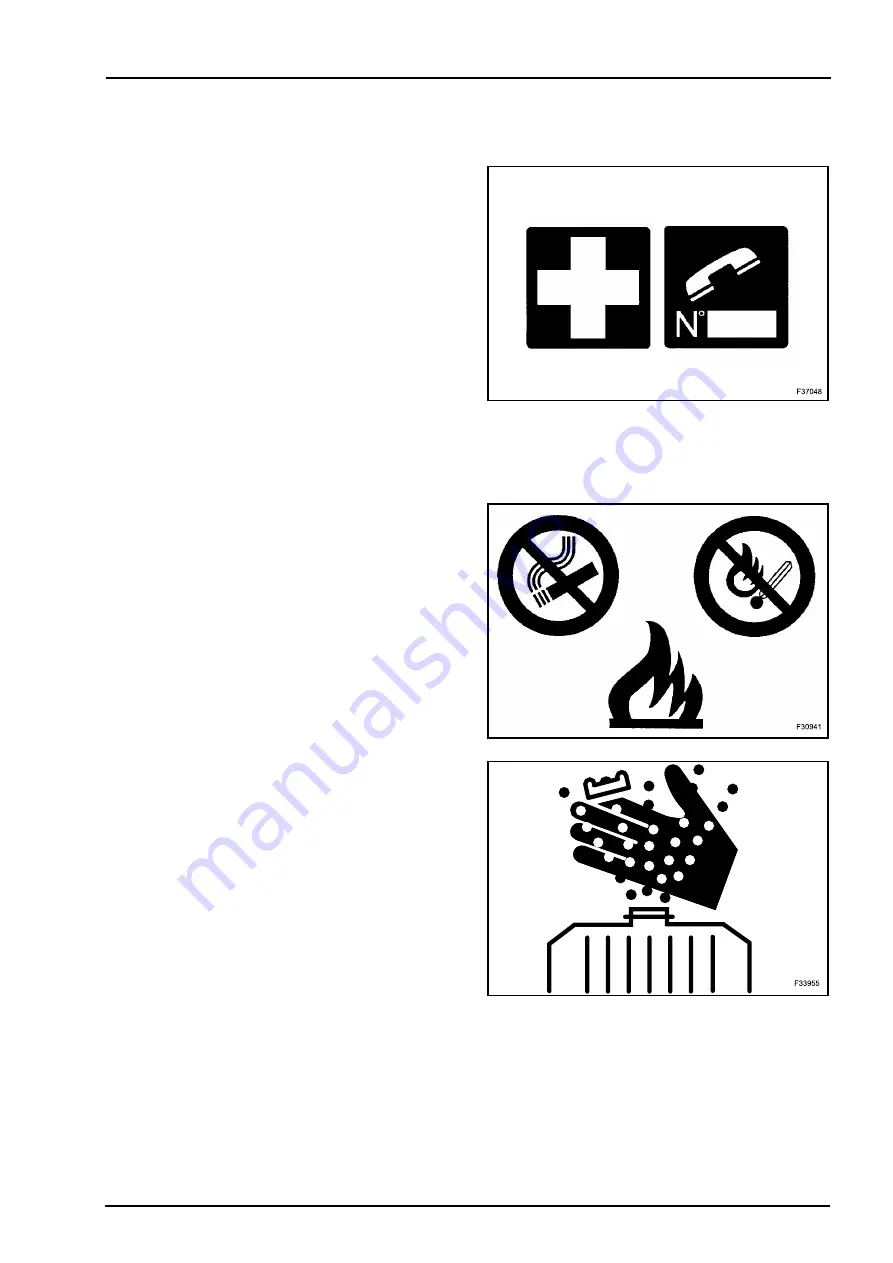

PREVENTION OF BURNS

The battery electrolyte generates severe burns.

The battery contains sulphuric acid.

Avoid any contact with the skin, eyes or clothing.

Antidote:

- EXTERNAL: rinse well with water, removing any

soiled clothing.

- INTERNAL: avoid vomiting. Drink water to rinse

your mouth. Consult a doctor.

- EYES: rinse thoroughly with water for 15 minutes

and get prompt medical attention.

When the electrolyte of a battery is frozen, it can

explode if you attempt to charge the battery or if you

try to start the engine using a booster battery.

Always keep the battery charged to prevent the elec-

trolyte freezing.

Batteries generate explosive gases.

Keep all flames, sparks and cigarettes away.

Provide good ventilation when changing a battery or

using a battery in an enclosed space.

Always protect your eyes when working near a bat-

tery.

Never touch the battery terminals with your hands.

This can induce a state of electrolysis and impair the

main organs of the body.

Hot coolant could spray out if the radiator cap is

removed while the system is still hot.

To remove the cap: allow the system to cool down,

turn the cap to the first notch and wait until there is

no more pressure.

Then remove the cap.

Summary of Contents for B100C

Page 1: ...B100C B100CLR B100CTC B110C B110CTC B115C Print No 84568042A Backhoe Loaders SERVICE MANUAL...

Page 5: ......

Page 13: ...INDEX...

Page 14: ...B100C B100CLR B100CTC B110C B110CTC B115C SECTION 00 SAFETY RULES...

Page 15: ...2 SECTION 00 SAFETY RULES...

Page 24: ...B100C B100CLR B100CTC B110C B110CTC B115C SECTION 01 MAINTENANCE...

Page 25: ...2 SECTION 01 MAINTENANCE...

Page 29: ...6 SECTION 01 MAINTENANCE NOTE...

Page 31: ......