10

•

Place the pre-compressed graphite rings (back seals)(195) onto

the seat.

•

Place seal ring (braided graphite) (129) into the groove of the ball

seat.

•

Place the ball seats into the body and the body cap using plastic

or wooden mallet or if necessary, using a hydraulic press.

All versions:

•

Place a trunnion bearing (99) into each trunnion plate (89) coun-

terbore.

•

Place a bearing spacer (91) over each ball trunnion.

•

Fit a trunnion plate over each ball trunnion until the plate rests

against the bearing spacer (91). This operation must be per-

formed with care and without excessive force or the bearing will

be damaged. It may be necessary to tap the plate on with a plas-

tic mallet.

•

Align the trunnion plates (89) relative to the ball port in the closed

position.

•

With the ball (3) in the "closed" position, lower the ball/trunnion

plate subassembly into the body (1).

NOTE:

This procedure is

critical and careful attention is a must. The outside diameter of

the trunnion plates must pilot in the body counterbore. Carefully

lower the subassembly until a trunnion plate enters the counter-

bore (Usually one trunnion plate will enter the counterbore and

the other will be out of position.) Use a plastic mallet or a block of

wood to rotate the second trunnion into position. Once trunnion

plates are aligned, lower the subassembly until the trunnion

plates are seated in the bottom of the counterbore.

•

Slide the thrust bearings (70=thinner, 71=thicker) over the shaft

(5). See the exploded view for proper orientation.

•

Insert shaft subassembly through the bonnet (8) and install pack-

ing (69). Refer to Fig. 11 for proper orientation of packing.

•

Install the gland (9) over shaft (5) and gland studs. Install the disc

springs sets (150) and the gland stud nuts (18) on studs and

tighten "finger tight."

•

Install the bonnet gasket (66) and the bonnet subassembly over

the bonnet studs (10). Note the correct shaft position! Lubricate

the threads of studs (13) and tighten the nuts (17) according to

values in Table 2.

•

Install the body gasket (65) in the body groove.

•

Place the body cap (2) carefully over the body studs (12) and the

body (1). See that the flange holes are aligned acc. to the mark

made during the dismatling. Take care not to damage the body

gasket and the seat (7) in the body cap.

•

Fasten the body nuts (16). Tighten the nuts gradually, always

switching to other side of the valve after every nut. The recom-

mended torques are given in Table 2. The flange faces must in

even contact with each other.

•

Mount the key (10).

•

Cycle the valve slowly a couple of times to insure correct position

of the ball between the two seats.

Tightening torques of the body joint bolting

•

Tighten the gland nuts (18) acc. to Section 4.2 . Pull on the shaft

(5) while tightening to assure that shaft and thrust bearings are

always in contact with the body. Check for leakage once the

valve is pressurized..

•

Install the valve in the pipeline as carefully and accurately as

when removing it. Follow the instructions given in Section 3.

5 TESTING THE VALVE

We recommend that the valve body be pressure tested after the

valve has been assembled.

The pressure test should be carried out in accordance with an

applicable standard using the pressure rating required by the

pressure class or flange drilling of the valve. The valve must be in an

half-open position during the test.

If you also want to test the tightness of the closure member, contact

the manufacturer.

NOTE

:

The shaft will fit into the ball in one position only. There’s a larger

cog in the splined shaft or added cog in square end shaft and a

matching groove in the ball shaft bore. It is essential to note the

groove’s position during the next assembly step.

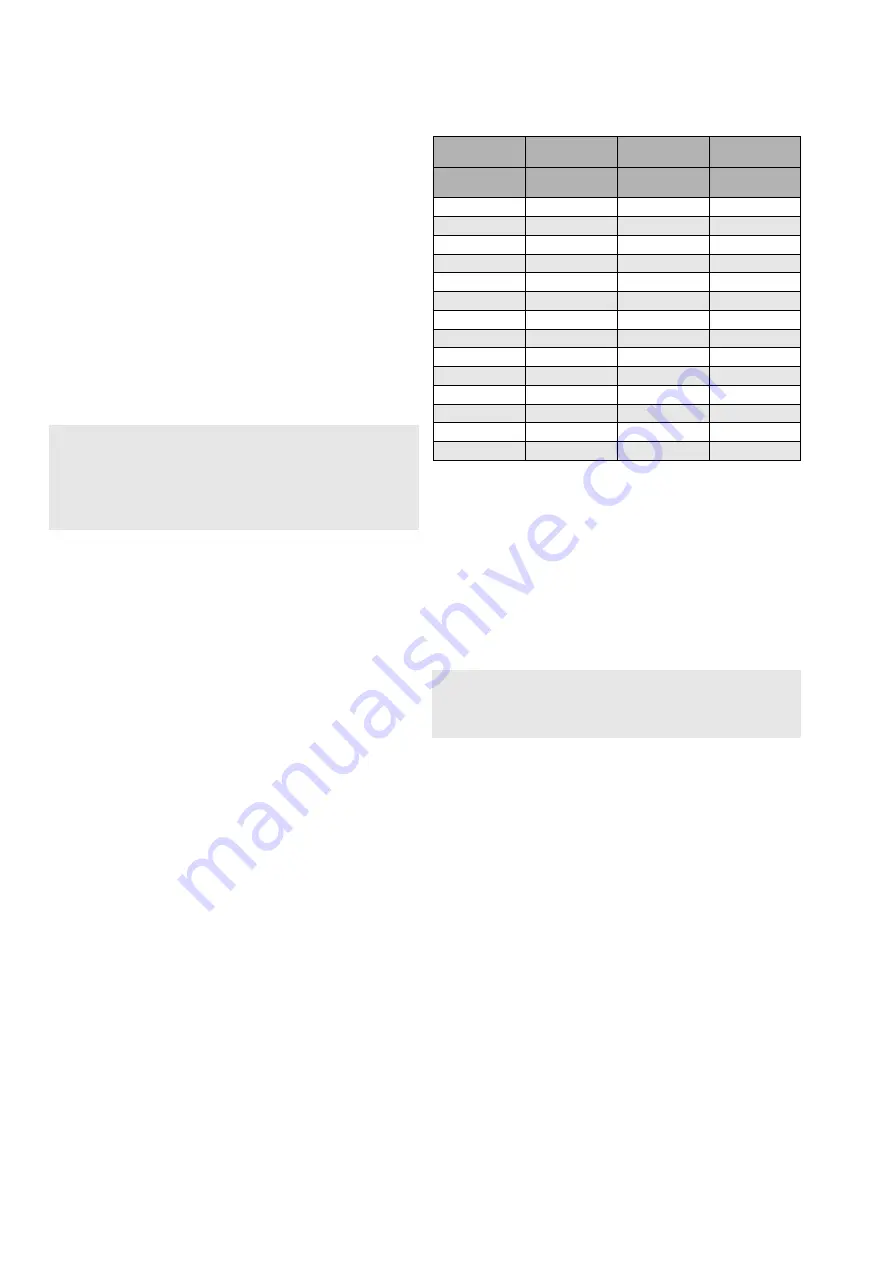

Material

ASTM A320 gr.

L7M

ASTM A193 gr.

B8M cl. 1

ASTM A193 gr.

B8M cl. 2

Bolt Size

Tightening

Torque (Nm)

Tightening

Torque (Nm)

Tightening

Torque (Nm)

M8

25

11

31

M10

50

22

60

M12

85

38

100

M14

140

61

170

M16

210

95

260

M18

290

130

350

M20

420

190

420

M22

560

250

560

M24

720

320

720

M27

1100

480

870

M30

1400

650

1200

M33

2000

880

1200

M36

2500

1100

1600

M39

3300

1500

2100

NOTE: Threads must be well lubricated

NOTE: ASTM A193 B8M cl.1 utilized in sizes 2"-16", ASTM A193 cl.2 utilized

in sizes 18"-24"

CAUTION

:

Pressure testing should be carried out using equipent conforming

to the correct pressure class!