10

3 R 71 EN - Issue 9/2020

•

Detach the retainer plates (42).

•

Detach the gland packings (20).

•

Remove the shafts (11 and 12), Fig. 24.

•

Lift the segment from the body.

•

Remove the bearings (15 and 16) and clean the bearing spaces.

•

Remove the seat by pushing it evenly inside the body.

4.7 Inspection of removed parts

•

Clean the removed parts.

•

See if the shafts (11, 12) and bearings (15, 16) are damaged.

•

Check if the sealing surfaces of the segment and the seat (4) are

damaged.

•

If necessary, replace the parts with new.

4.8 Assembly

•

Put the bearings (15, 16) in their places.

•

Mount the seat as explained in Section 4.5.2.

•

Mount the segment in the body in the closed position. Press the

segment to fit the shaft (12).

•

Install the drive shaft (11). Note the location of the pin hole and

the keyway. See Fig. 25.

•

Please note the depth of the hole (L) for the conical pin (Fig. 23).

Put the pins (14, 50) in their places and lock them (Fig. 26). Both

pins are locked with TIG welding in the high-consistency acid-

resistant version and in the standard and high-consistency tita-

nium versions. Moreover, the drive shaft is welded to the seg-

ment in the high-consistency versions. Contact the manufacturer

for more information.

•

Install the blind flange (10) with gaskets (19), tighten the bolts

(26), see Table 2.

•

Install the gland packing (20) and retainer plates according to

Section 4.2.

Table 2

Screw torques (for lubricated screws)

5 TESTING THE VALVE

We recommend that the valve body be pressure tested after the

valve has been assembled.

The pressure test should be carried out in accordance with an

applicable standard using the pressure rating required by the

pressure class or flange bore of the valve. The valve must be in the

open position during the test.

If you also want to test the tightness of the closure member, contact

the manufacturer.

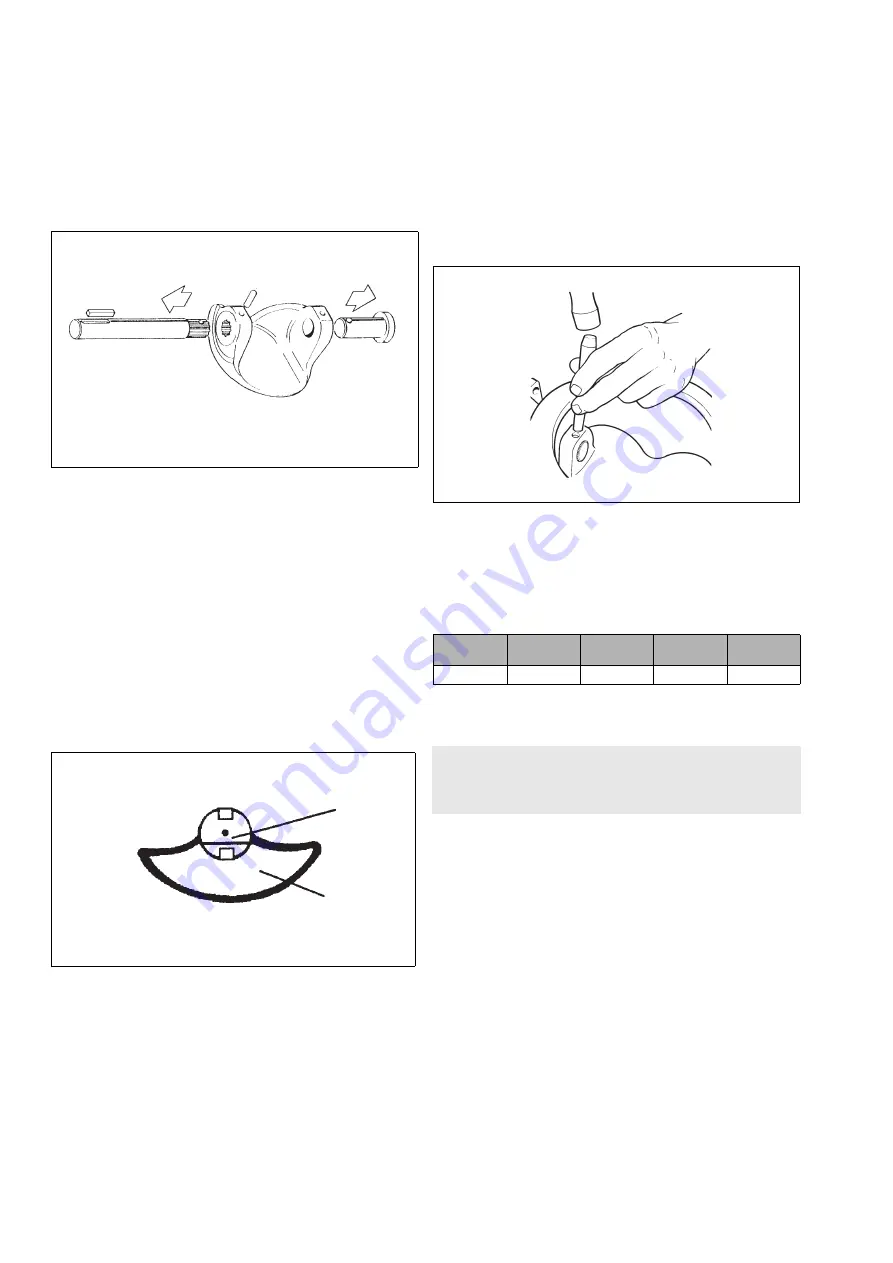

Fig. 24

Removing the shafts

Fig. 25

Segment and shaft position

SHAFT WITH KEYWAY

marker line

segment ball surface

Fig. 26

Locking a pin

Screw

M6

UNC 1/4

M8

UNC 5/16

M10

UNC 3/8

M12

UNC 1/2

Torque, Nm

8

18

35

65

CAUTION:

Pressure testing should be carried out using equipment

conforming to the correct pressure class!