FlexPAK

7 Troubleshooting

and the included electrical diagrams.

There is no overcurrent relay. The frequency converter parameter for maximum current is adjusted from the

factory and is not to be adjusted.

If a fault occurs which cannot be adjusted according to the following descriptions, a Nederman service techni-

cian is to be called.

7.1 Tools

To carry out troubleshooting, it is necessary to have a multimeter with V DC and ohm measuring capabilities.

7.2 Remove the lid of the start and control unit

Remove the lid as follows:

1 Unscrew the four plastics screws in the corner of the control cabinet.

2 Lift of the lid.

3 Identify the PLC and the terminals at the bottom of the cabinet.

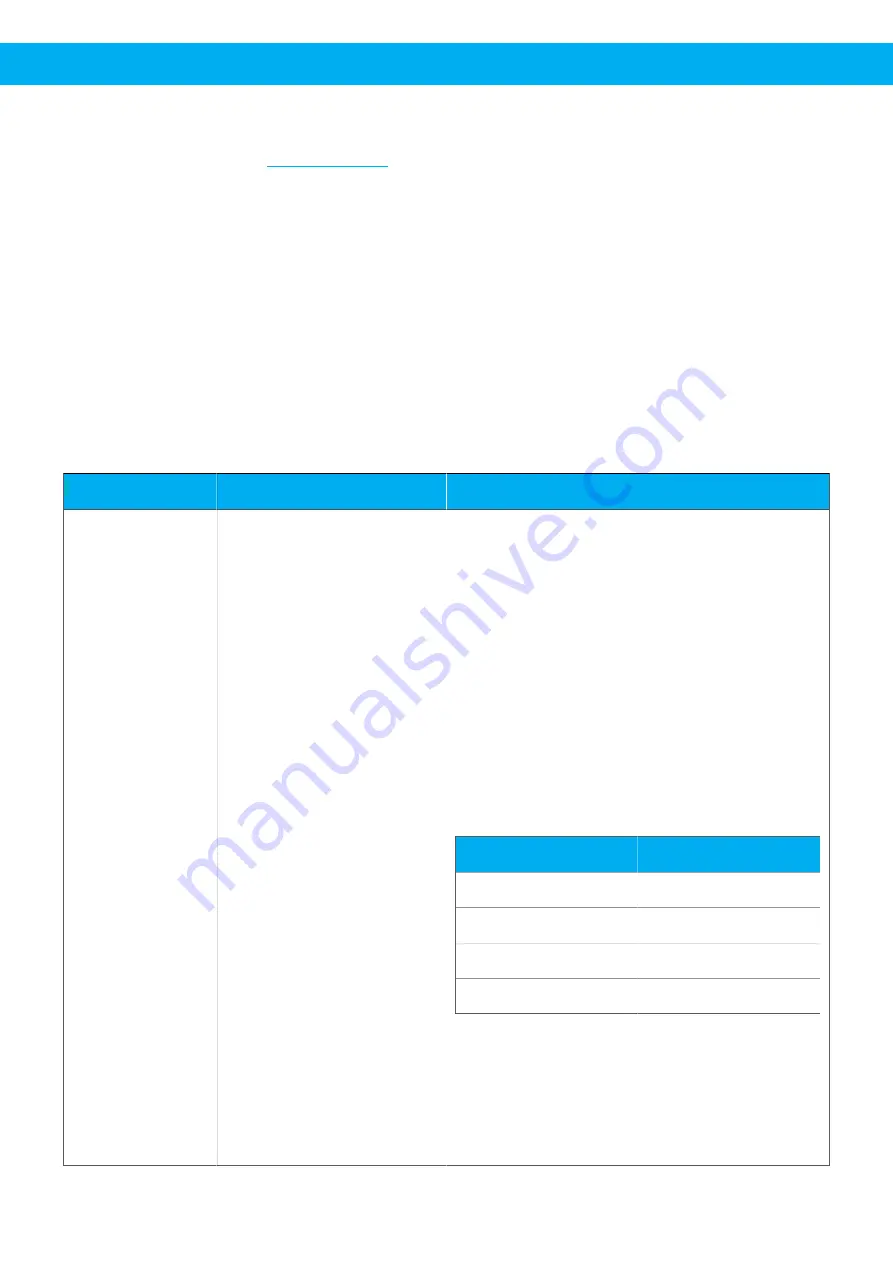

Table 7.1 Troubleshooting guide

Error

Possible cause

Solution

The unit unexpec-

tedly goes directly

into Running mode

when the Standby/

Running button is

pressed.

• A valve at a workstation is open

and its micro switch is activated

• The PS cable is damaged with

its wires short-circuited

If the PS cable is damaged, press the Standby/Running but-

ton to put the unit into Off mode and investigate the fault.

If necessary, loosen the PS cable from the control unit, see

the electrical diagrams, and use an ohmmeter across the

leads in turn to locate the fault.

Defect PT100 tem-

perature sensor.

Check whether the PT100 sensor is defective as follows:

1 Disconnect the PT100 sensor wire from terminal 77

and measure the resistance between terminal 78 and

the disconnected sensor wire.

2 Measure the resistance in the sensor using an ohm-

meter. The values in the table below are standard val-

ues, so a deviation from the measured value is normal.

If the averaged output (in ohm) deviates more than

±2% from these values, the sensor will need to be re-

placed.

Temperature (°C)

Averaged output (ohm)

0

100

20

110

80

131

135

150

If the sensor has a resistance >150 ohms, there will be a

high-temperature alarm. To check whether the sensor in-

put is working correctly, disconnect the PT100 wire at ter-

minal 77 and connect a jumper between terminals 77 and

78. Press the OK button on the PLC to reset the alert.

If the alert disappears, the PT100 sensor input is working,

and the PT100 sensor will need to be replaced.

21

Summary of Contents for FlexPAK Series

Page 6: ...FlexPAK 13 12 10 9 7 8 2 1 3 4 6 5 11 3 11 7 8 9 12 13 15 14 18 19 10 17 4 16 15 20 5 6...

Page 7: ...FlexPAK 6 1 2 3 6 7 8 9 16 15 14 13 11 10 12 4 5 7 7...

Page 9: ...FlexPAK 2 1 4 5 6 8 7 9 3 9 1643 1mm 65 662 1mm 26 2 1771 4 1mm 70 1 10 9...

Page 10: ...FlexPAK 11 12 13 14 10...

Page 11: ...FlexPAK A A A A C Min 2 1m 83 15 1 0 m 39 4 16 A B C 17 11...

Page 29: ...www nederman com...