www.nederman.com

• To avoid pressure losses and dust deposits in the system it is

important to use the correct duct diameter. The transport velocity

shall be at least 10–12 m/s (2000–2400 ft/min) for fume and 15–20

m/s (3000–4000 ft/min) for dust. Take velocity into account when

choosing the duct diameters. The velocity should never decrease en

route to FilterMax C25. The following duct diameters can be used

for the connection to FilterMax C25: Ø250 mm (10”) for the inlet and

Ø315 mm (12”) for the outlet.

• Use long radius bends and no t-pieces.

• Install plenty of cleaning access points in the ducting system before

FilterMax C25.

• If the dust is abrasive it may be necessary to use thick walled (or rub-

ber coted) material in bends and other exposed areas.

• To avoid pressure losses the ducting system should be as short as

possible and designed with two or more branches.

• Use larger diameters on the clean side to reduce pressure losses.

• Use fire dampers when the duct system is passing from one fire zone

to another. NB! Fire dampers do not stop explosions!

• Install a flow meter in the outlet duct, at least 3 m (10 ft.) from the filter

outlet.

• If there is a significant fire risk, it is better to install several small sys-

tems then one large system.

• Install a sparktrap to prevent sparks or burning/glowing material from

entering the FilterMax C 25.

• At welding work on oiled material the filter cartridges should be trea-

ted with fine lime powder (approx. 60 g) before the first start.

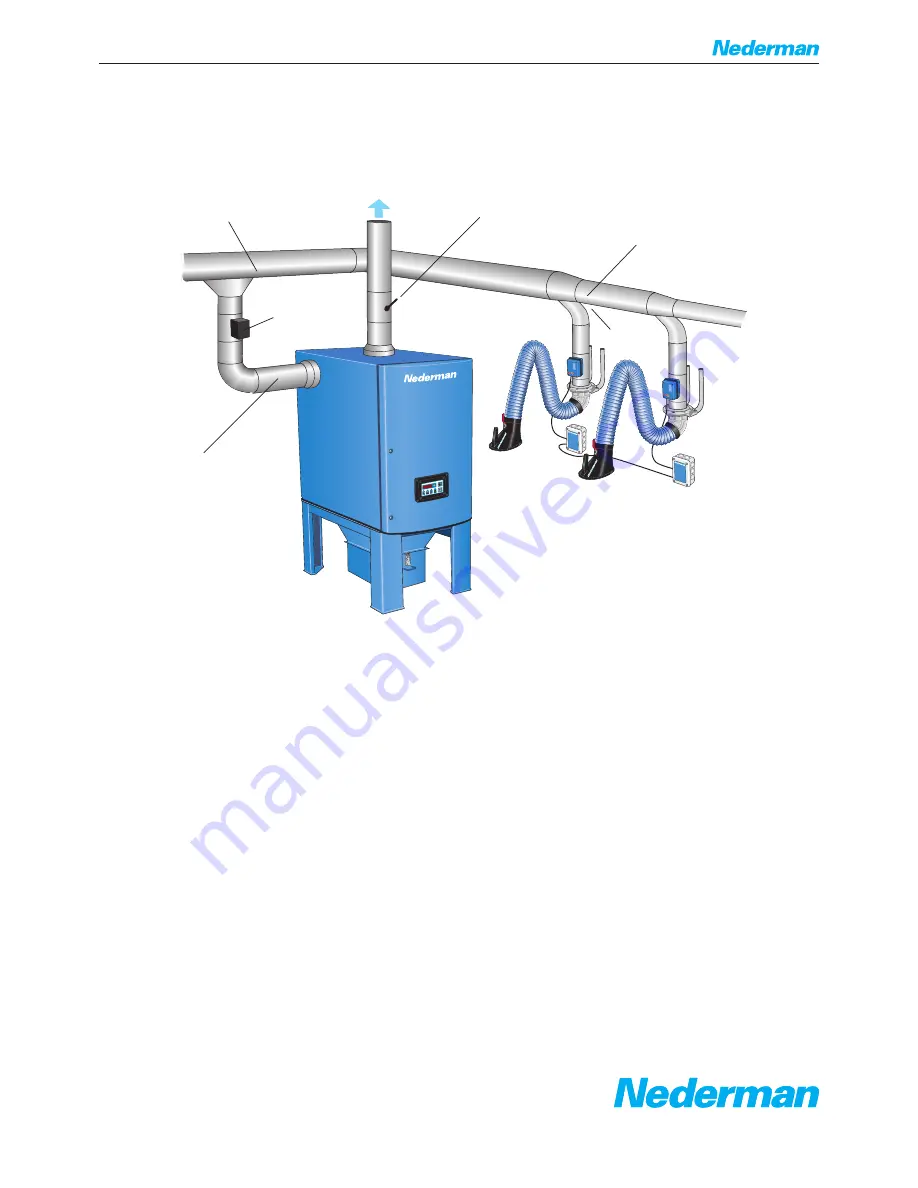

System installation

NB! To adsjust the air flow, a

regulatiing damper in the clean

air duct can be used

Cleaning access point

The inlet on the opposite side

is used as a cleaning and

inspaction acces point

Cleaning access point

After cleaning

damper

Cleaning

access point

Nederman Original

Fume Extractors with

automatic dampers

30–45°

www.nederman.com

FilterMax C25