Vacuum Hose Reel 881 EX

7 Maintenance

For service and technical support, please contact AB

Ph. Nederman & Co.

Make sure the inside of the hose reel and the connec-

tion pipes are free from deposits. A build-up of depos-

its inside the piping system may cause a discharge of

static electricity.

Make sure the outside of the hose reel is free from

dust layers.

Oily and sticky substances can sometimes stick to the

damper blade resulting in jamming so that the damper

does not close completely. The reel must then be dis-

mantled for cleaning.

WARNING! Risk of personal injury

Waste material collected in Vacuum Hose Reel

881 EX can constitute a health risk. Always

check the safety requirements related to the

specific waste when handled.

7.1 Service instruction

Check the following points at least once a year. Take

action when necessary.

• Check that the reel is secured in the ceiling or on the

wall.

• Check the duct connections for leakage.

• Check the hose for damage.

• Check the coiling function of the hose. Adjust the

spring tension when necessary.

• Check the operation of the damper. The damper

should open automatically when the hose is pulled

out.

• Check that there is enough suction in the exhaust

hose. If not, check the damper function and the hose

for holes and damage.

• Check that the operating device is not damaged.

7.2 Service and maintenance of ATEX

equipment

To ensure the required level of protection with re-

gards to the equipment category, check the following

points:

• Ensure that the Vacuum hose reel is regularly in-

spected for damage or malfunction. If the vacuum

hose reel is damaged it must be repaired immedi-

ately.

• Ensure that no explosive atmosphere and/or dust

layers are present when cleaning, servicing or in-

specting the hose reel.

• Ensure that only original (OEM) spare parts are used.

• Ensure that the reel is not covered with thick dust

layers (>5 mm). This is prevented by setting up

routines for regular cleaning and including these in

the explosion protection document.

NOTE!

The ATEX classification is only valid when Ne-

derman spare parts are used.

8 Spare Parts

CAUTION! Risk of equipment damage

Use only N

$

e

$

d

$

e

$

r

$

m

$

a

$

n

$

original spare parts and ac-

cessories.

Contact your nearest authorized distributor or

N

$

e

$

d

$

e

$

r

$

m

$

a

$

n

$

for advice on technical service or

if you require help with spare parts. See also

w

$

w

$

w

$

.

$

n

$

e

$

d

$

e

$

r

$

m

$

a

$

n

$

.

$

c

$

o

$

m

$

.

8.1 Ordering spare parts

When ordering spare parts always state the following:

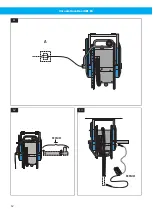

• The part number and control number (see the

product identification plate).

• Detail number and name of the spare part (see

w

$

w

$

w

$

.

$

n

$

e

$

d

$

e

$

r

$

m

$

a

$

n

$

.

$

c

$

o

$

m

$

/

$

e

$

n

$

/

$

s

$

e

$

r

$

v

$

i

$

c

$

e

$

/

$

s

$

p

$

a

$

r

$

e

$

-

$

p

$

a

$

r

$

t

$

-

$

s

$

e

$

a

$

r

$

c

$

h

$

).

• Quantity of the parts required.

9 Recycling

The product has been designed for component mater-

ials to be recycled. Different material types must be

handled according to relevant local regulations. Con-

tact the distributor or

$

N

$

e

$

d

$

e

$

r

$

m

$

a

$

n

$

if uncertainties arise

when scrapping the product at the end of its service

life.

EN

21

Summary of Contents for 30805881

Page 9: ...Vacuum Hose Reel 881 EX 3a Ø38 mm L 160 170 mm Ø50 mm L 220 230 mm 3b 1 7 Nm 3c 9 ...

Page 10: ...Vacuum Hose Reel 881 EX 4 A B C 5 6 A 7 10 ...

Page 11: ...Vacuum Hose Reel 881 EX A 8 9 A B 10 11 ...

Page 12: ...Vacuum Hose Reel 881 EX A 11 R 1MΩ 12 R 1MΩ 13 12 ...

Page 14: ...Vacuum Hose Reel 881 EX 38 mm m3 h kPa 16 50 mm kPa m3 h 17 14 ...

Page 120: ...www nederman com ...