NCF

EN

20

4.3

Installation types

WARNING!

Risk of personal injury.

•

Even with guards installed (regardless of the conditions of supply or installation),

the fan may be dangerous due to the effects of indrawn or moved air.

•

It is advisable to adopt precautions that prevent access to the room containing

the fan while it is operating, or to keep persons away with fixed guards that

maintain a safe distance from the intake opening.

•

Check the efficiency of all guards every month. In case of wear, damage or

breakage, replace them immediately.

•

The user is responsible for the selection of equipment, ropes, belts and chains

best suited for both load and functionality.

•

Unless otherwise specified by contract, the fan and guards are suitable for

installation as a single unit, and must not be subjected to effects of fluid dynamics

caused by other machines installed in the same fluid movement system.

•

On starting and in compliance with programmed maintenance intervals, check

that nuts and bolts are correctly tightened.

•

A safety procedure for access to the fan must be compiled, taking into

consideration the indications provided by the manufacturer, information deriving

from the analysis of risks at the installation point and safety requirements in

workplaces.

•

The client and/or the installer of the electric system is responsible for choosing

the equipment and cables used for connecting the fan electrically, based on the

dimensions of the motor installed and the characteristics of the main power

supply.

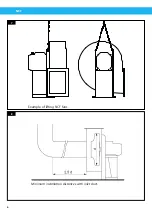

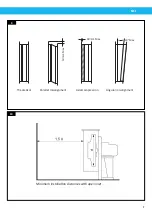

There are four possible installation types, in compliance with UNI 10615 specifications:

•

Type A: open intake and outlet.

•

Type B: open intake and outlet connected to a pipe.

•

Type C: intake connected to a pipe and open outlet.

•

Type D: intake and outlet connected to a pipe.

Clearly AB Ph. Nederman & Co cannot be aware of which of these four installation types

will be used by the user. Therefore, the installer or end client themselves must analyze the

risks involved for the chosen installation type used in the specific application.

Depending on the applications that the client intends to use the fan for and on the type of

installation chosen, the following safety shields must be fitted:

•

Type A installation: fixed shields at the intake and outlet.

•

Type B installation: shield fitted only at the intake.

•

Type C installation: shield fitted only at the outlet.

•

Type D installation: no shield at either the intake or outlet.

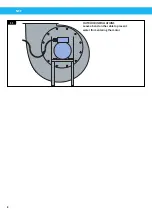

The shielding must be constructed to impede access to the parts of the fan that could

cause injury. It must be robustly built enough to stand the vibrations and stress caused

by the machine and by environmental conditions. It must be securely fixed in position by

devices that will not become loosened by vibrations and that cannot be removed without

the use of tools.

It is, in any case, the person installing the fan who is responsible for ensuring that adequate

measures have been taken to prevent accidental contact with the fan’s moving parts.

The installer and the user must also take into account other types of risks present, in

particular those caused by foreign matter entering the fan and the aspiration of explosive,

inflammable or toxic gases at high temperatures.