12

|

ni.com

|

NI ISM-7401/7402 User Manual

Using the Optional Encoder

There are three versions of the NI ISM-7401 and NI ISM-7402: the NI ISM-7401/7402 has a

single shaft, the ISM-7401D/7402D has a dual shaft, and the ISM-7401E/7402E has a dual shaft

with a 1000-line, incremental encoder assembled to the rear shaft of the unit. You can connect

the A, B, and Index (Z) channel signals of this encoder to the external controller for position

verification and enhanced performance, depending on the features of the controller. To facilitate

connecting the encoder signals to your external controller, you should purchase cable part

number 748995-01.

Note

If you are making your own cable to connect the encoder signals to your

controller, NI recommends using a shielded cable with four or five twisted pairs for

improved noise immunity.

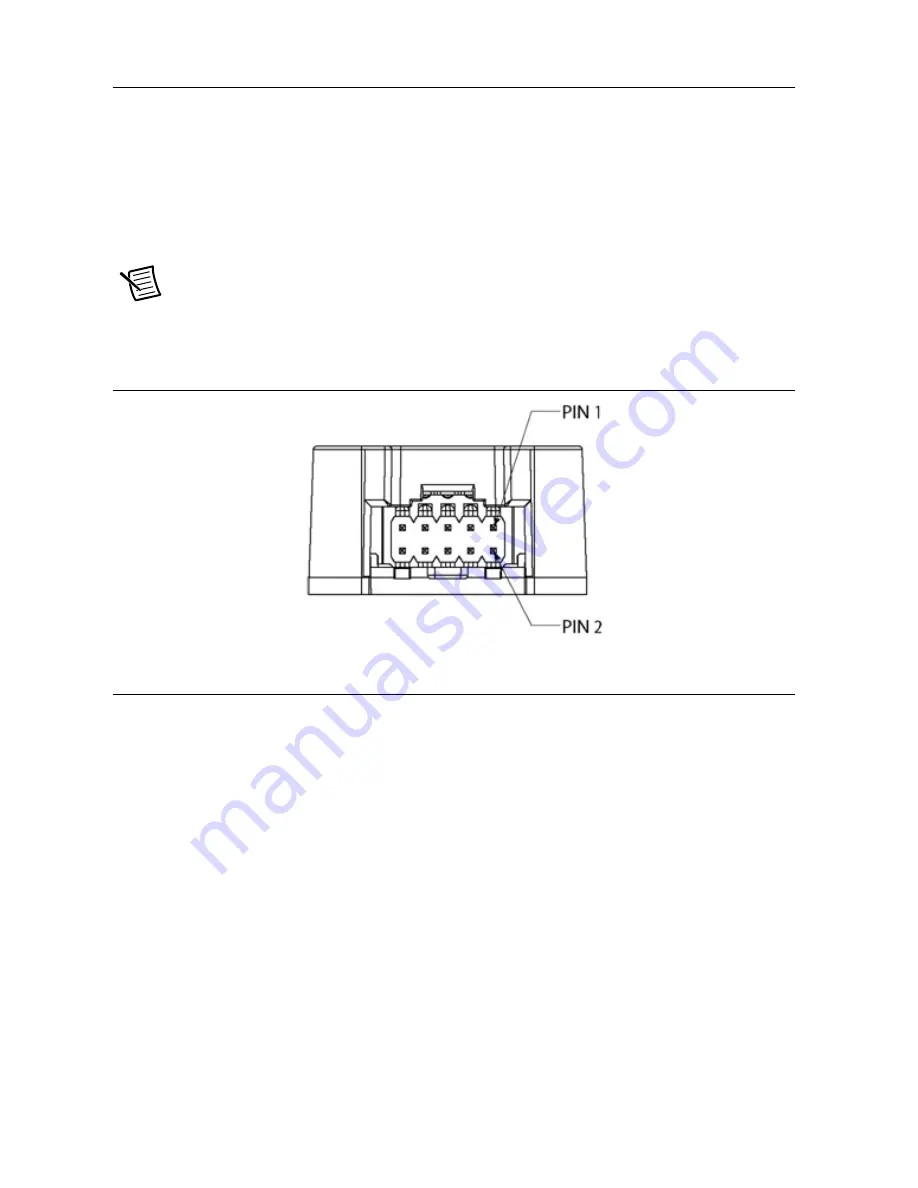

Figure 16.

NI ISM-7401/7402 Encoder Connector

Configuring the NI ISM-7401/7402

Setting the Current

Set the current to 100% to achieve maximum torque. However, under some conditions you

might want to reduce the current to save power or lower motor temperature. This is important if

the motor is not mounted to a surface that will help it conduct heat away or if you expect the

ambient temperature to be high.

Step motors produce torque in direct proportion to current, but the amount of heat generated is

roughly proportional to the square of the current. If you operate the motor at 90% of rated

current, the motor provides 90% of the rated torque and approximately 81% as much heat. At

70% current, the torque is reduced to 70% and the heating to about 50%.