with the same file name in the same folder location so the sequence file can load it

correctly.

Related Information

mmWave OTA Validation Positioner Control Panel

on page 35

on page 38

Programming

Soft Front Panels

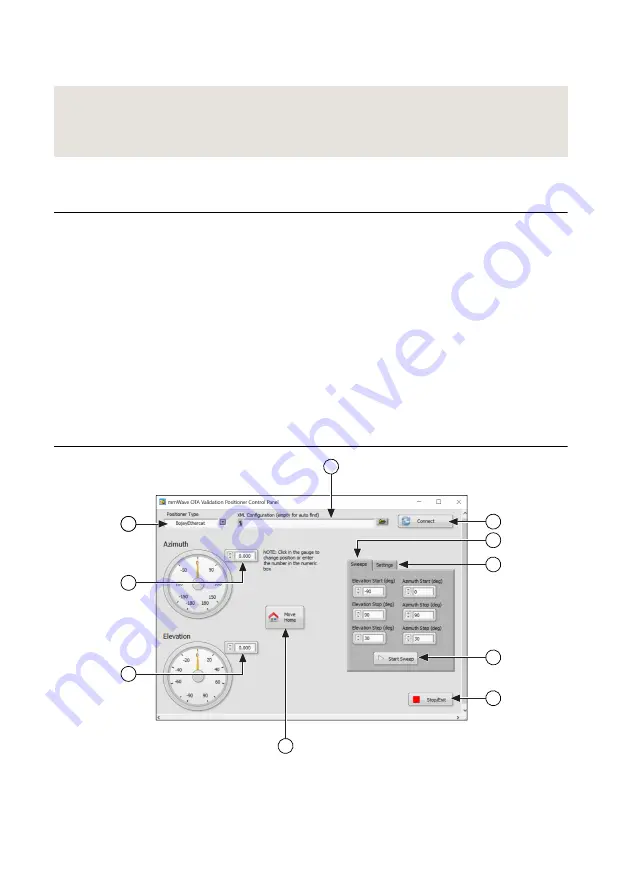

mmWave OTA Validation Positioner Control Panel

The mmWave OTA Validation Positioner Control Panel allows you to quickly manipulate the

positioner.

You can complete the following tasks with the mmWave OTA Validation Positioner Control

Panel:

•

Move the azimuth or elevation independently

•

Configure a sweep in both azimuth and elevation

•

Configure the Absolute Zero location of the positioner for antenna alignment

Figure 11. mmWave OTA Validation Positioner Control Panel Environment

1

10

8

2

3

4

1

9

5

6

7

1.

XML Configuration

—Browse to the file location of the XML configuration you want to

load. Leave the field blank to automatically detect the file location.

2.

Positioner Type

—Select the positioner used with your configuration.

mmWave OTA Validation Test Reference Architecture

|

© National Instruments Corporation

|

35