©

National Instruments Corporation

A-1

cFP-20xx and cFP-BP-x User Manual

A

Troubleshooting

This appendix gives troubleshooting instructions for the cFP-20

xx

and

FieldPoint software. For more troubleshooting information, refer to the

Measurement & Automation Explorer Help for FieldPoint

and the

Measurement & Automation Explorer Remote Systems Help

.

Runaway Startup Application

If a runaway startup application causes the cFP-20

xx

to become

unresponsive, you must power down the cFP-20

xx

, then reboot it with

either the DISABLE VI switch or the SAFE MODE switch in the ON

position. Rebooting the controller with the DISABLE VI switch ON

prevents any VIs from running at startup. Rebooting with the SAFE MODE

switch ON starts the cFP-20

xx

in safe mode, and the embedded LabVIEW

RT engine is not launched. Refer to the

section of Chapter 3,

, for more information about these DIP switches.

STATUS LED Error Indications

The cFP-20

xx

indicates specific error conditions by flashing the red

STATUS

LED a specific number of times. Table A-1 describes the

STATUS

LED flashing sequences and the corresponding error condition.

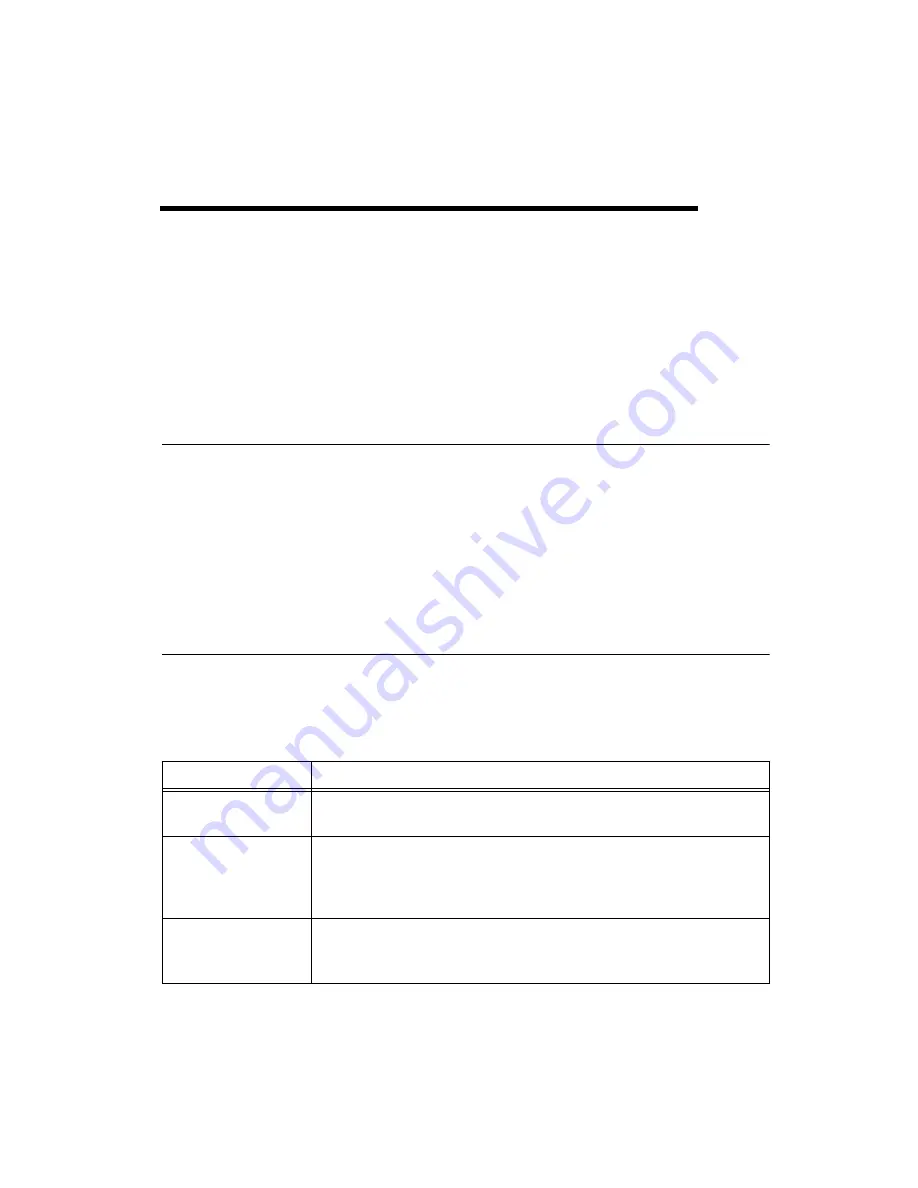

Table A-1.

STATUS LED Flashes and Corresponding Error Conditions

Number of Flashes

Error Condition

0 (stays lit)

The cFP-20

xx

did not power on correctly. Contact National Instruments

for assistance.

1

The cFP-20

xx

is in reset mode or is unconfigured. Make sure the RESET

IP switch is in the OFF position and restart the controller. Refer to the

Measurement & Automation Explorer Help for FieldPoint

for more

information about configuration.

2

The cFP-20

xx

has detected an error in its firmware. This usually occurs

when an attempt to upgrade the firmware is interrupted. Repeat the

firmware upgrade process.