Machine Operation

www.nationalequipment.com

Phone: 763-315-5300

13

CONCRETE

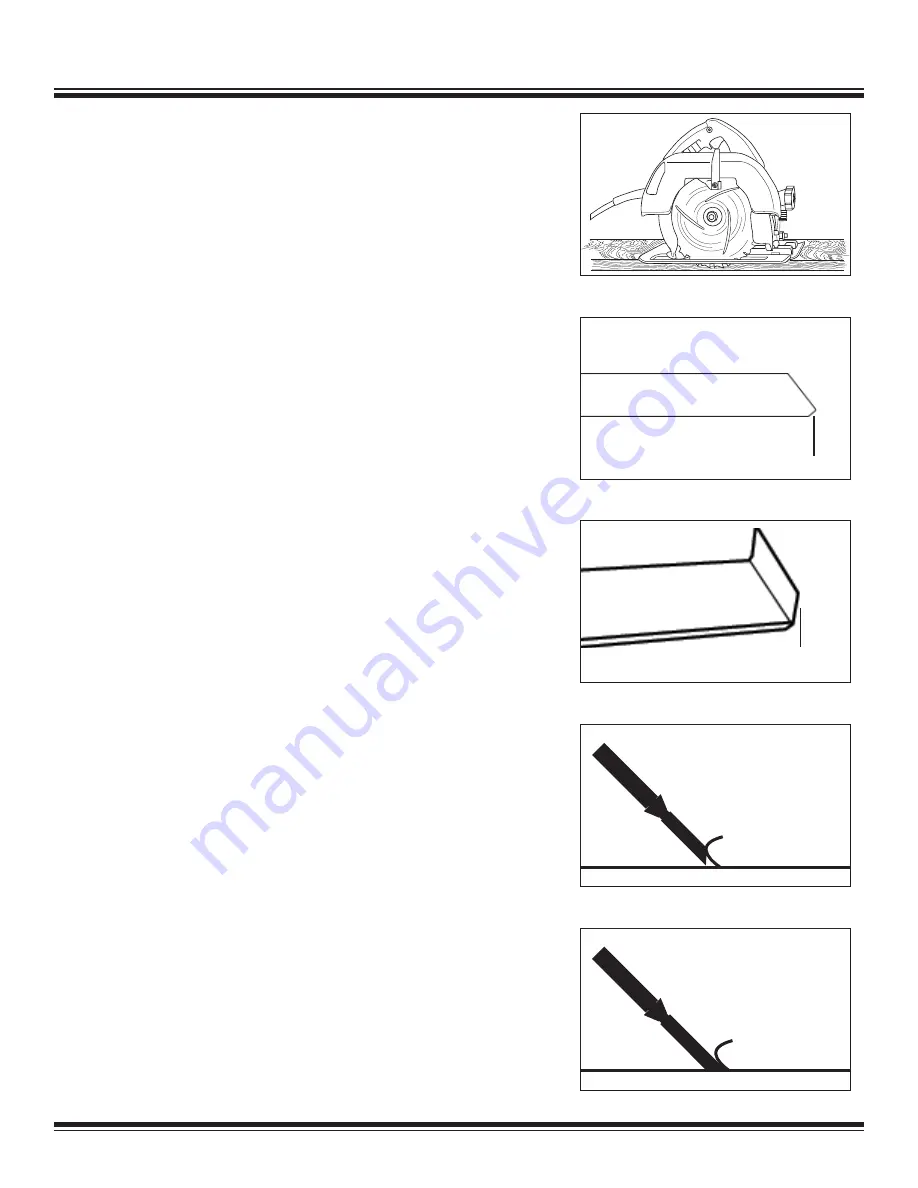

When working on concrete slab, normal blade position is bevel up for best performance,

especially when cleaning adhesive. On occasion, bevel down gives better blade life. Test

each job for best performance.

GIBCRETE AND SOFT POURED FLOORING

Requires blade bevel down to create a better wearing surface.

HARD TO REMOVE SURFACES

Ripper teeth can be used on hard surfaces to remove material (hardwood & VCT).

GLUED HARDWOOD FLOORING

A 6” blade is recommended for regular adhesive. For proper removal of hardwood fl oor-

ing (parkay laminated, plank laminated, plank solid) fl ooring must be scored. This is done

by using a circular saw set at a depth of 100% of the thickness of the board, just missing

the subfl oor surface when on concrete. (See Figure P) A chalk line for scoring lines can

be used across the fl oor the width of the blade. A ripping guide attached to the saw can

be used to eliminate chalk line marks. Open an area large enough to fi t machine or start

from a doorway. It is important to keep all debris cleaned up for maximum performance of

machine. Ture parkay scoring will come up in small pieces so scoring is not necessary.

BLADE SHARPENING

Always check for blade sharpness before using; dull blades greatly reduce cutting ef-

fectiveness. Over time, used blades will develop a back bevel (Figure Q); when sharpen-

ing, blades will not recover until the back bevel is completely leveled out. NOTE: Thinner

blades are easier to sharpen, but they also break easier.

•

Always wear gloves and safety glasses.

•

Grind blade using a 4” diameter disk with 120 or fi ner grit. Be careful not to catch

disk on edge or corner of blade.

•

Pass grinder along blade edge starting on one end and continuing in one direction

being careful to hold grinder at proper angle of blade. Grind until sharp.

•

Using a high quality fi ne tooth hand fi le, follow the same procedure as above.

•

Blades are sharp. Use extreme caution.

•

Have plenty of sharp blades on each job so on-the-job blade sharpening is elimi-

nated.

•

It is best to re-sharpen dull blades on proper bench or belt grinder in the shop, so

the blades are ready for the next job.

SELF-SCORING BLADE SHARPENING

It is important to keep the “wings” on these self-scoring blades sharp. Use a fi le on the

edge. Sharpen the fl at part of the blade, the same way as described above.

CARBIDE TIPPED BLADE SHARPENING

To sharpen carbide tipped blades, a carbide grinding wheel is necessary, ie: silicon

carbide or green wheel.

FIG. C

FIG. D

FIG. E

BEVEL UP

BEVEL DOWN

Front of Blade

Back Bevel

Self-Scoring Wing

Front of Blade

Summary of Contents for 550

Page 1: ...Read Manual Before Operating Machine ADJUSTABLE HANDLE SCRAPER INSTRUCTION MANUAL 101713...

Page 2: ......

Page 26: ......