Pull

Push

Loosen

Electric Connector

Cap

Air Cap

Ait Joint

Quick Release

Ring

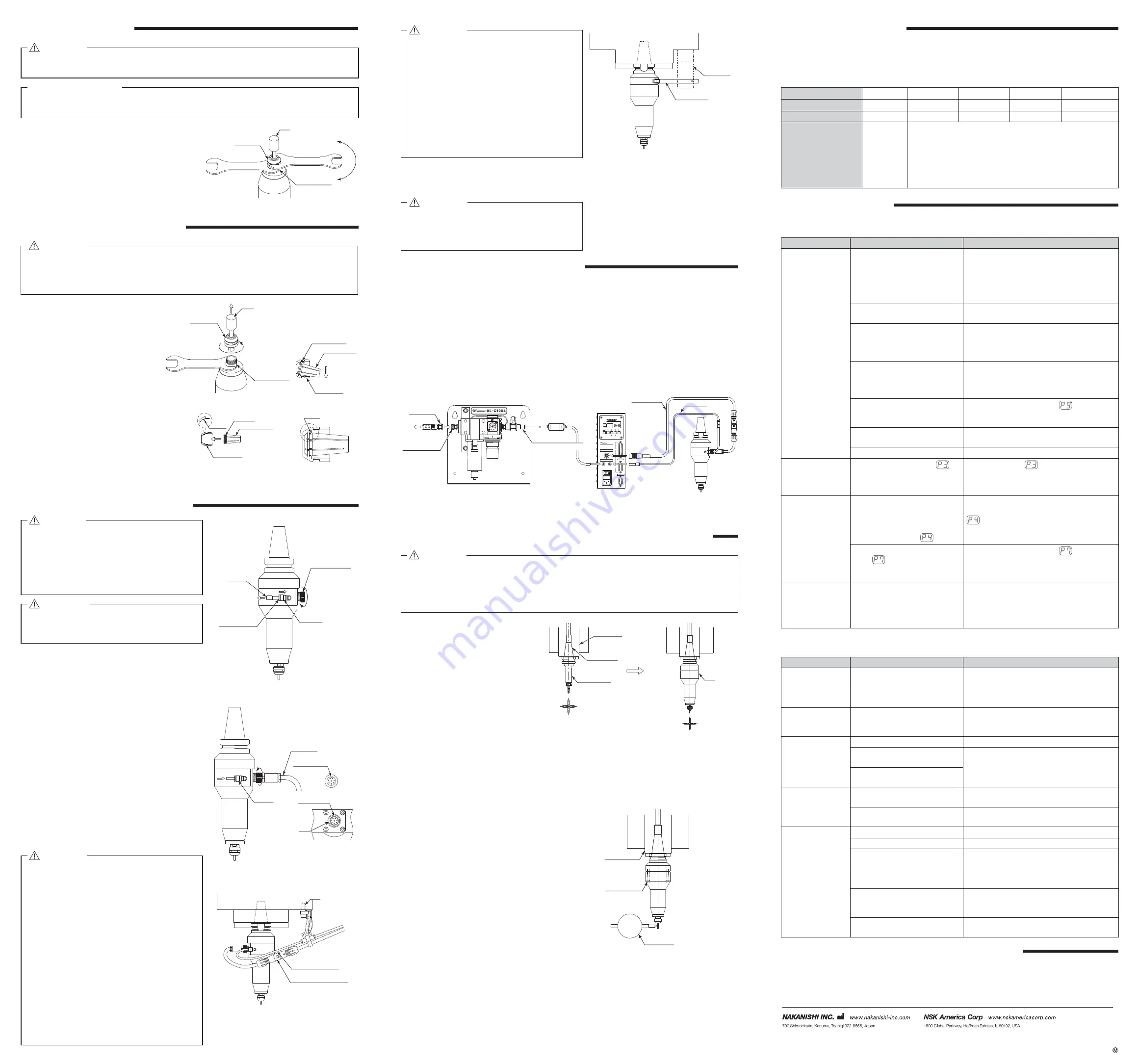

①

Insert and Clamp the HES Brushless Motor Spindle to the

main spindle of the machining center.

②

Remove the Electric Connector Cap from the HES

Brushless Motor Spindlee by turning counterclockwise

(Fig. 20).

③

Remove the Air Cap from the HES Brushless Motor

Spindle's Air Joint (Fig. 20).

④

Install the

ȭ

4mm air hose on the HES Brushless Motor

Spindle's Air Joint (Fig. 21).

⑤

Detach the plug cap for motor cord and install the motor

cord to the HES Brushless Motor Spindle's plug. Please

make sure to align the pin on the plug and the groove on

the motor cord connector. Turn the motor cord connector

clockwise to tighten (Fig. 21, 22).

⑥

Fixture the Emergency Connector in the machine. Route

the motor cord and air hose and hold them securely with

enough slack to allow for quill travel. The Emergency

Connector should be positioned horizontally and the air

hose should not have any severe bends. Make sure air

can pass freely through the air hose. If the motor cord and

air hose are not held properly, the emergency connectors

may not separate properly in an emergency (Fig. 23).

Fig. 20

Spindle Housing

Motor Cord Connector

Alignment Hole

Alignment Pin

Insert

Tighten

Motor Cord

Air Joint

Plug

Fig. 21

Fig. 22

Emergency Connector

Emergency Air Joint

Bolt

Fig. 23

Block

(Not Provided)

(Accessories)

Lock Bar

Fig. 24

①

Connect the Motor Cord and Air Hose as shown in Fig. 25.

②

An Air Line Kit such as NAKANISHl'S (AL- C1204) must be used. The CONTROLLER and the HES Brushless

Motor Spindle must be supplied with clean, dry air regulated to between 0.25MPa - 0.3MPa Connect the output

of the Air Line Kit to the CONTROLLER's Air In connector. If you are not using NAKANISHl'S Air Line Kit, you

must use a regulator and air

¿

lter or dryer to supply clean, dry, regulated air to the CONTROLLER and the HES

Brushless Motor Spindle.

Water contamination in the air will cause damage to the Brushless motor and spindle.

※

For details of the operation and connections of the CONTROLLER and Air Line Kit please refer to their

respective Operation Manuals.

③

Do not attempt to start the HES Brushless Motor Spindle until you have completed and double checked all the

procedures described in this Operation Manual. Absolutely DO NOT ROTATE the MACHINE'S MAIN SPINDLE

after installing the HES Brushless Motor Spindle.

Motor Cord

Air Hose

CONTROLLER

To Air Compressor

SERIAL I/F

LOAD

RUN

×

1000min

-1

WARNING

SPEED

UP

DOWN

ERROR

RESET

GEAR

CTRL

DIR

START

STOP

AUTO

FWD

MANUAL

REV

NE260

E3200 SERIES CONTROL UNIT

MOTOR

AIR

A

B

EXT I/O

IN

OUT

Primary Joint

Connector for

Air Hose

Connection

Hose

Secondary Joint

ȭ

6 One - Touch Joint

Fig. 25

①

To

¿

nd the main spindle's center, mount

a tool in a highprecision end mill holder

and machine the pattern described

below and measure the center. Or use

a 1/4" collet chuck (Option) and mount

an edge

¿

nder in the collet chuck to

determine the true centerline of the HES

Brushless Motor Spindle.

②

To adjust the HES centerline, mount

the HES Brushless Motor Spindle in the

machining center's quill and use a dial

gauge on a test pin. Loosen the six bolts

that hold the taper housing together,

slightly and tap out the X-Y eccentricity.

Rotate the machining center's spindle by

hand to Main Spindle verify concentricity.

(Fig. 28)

Main Spindle

Spindle Taper

Tooling Holder

Mill an X-Y cross pattern in

a scrap piece and measure

the X-Y intersection.

Mount the HES Brushless Motor

Spindle in the quill and mill the same

cross pattern with a smaller diameter

tool inside the previously milled

pattern. Measure the difference in the

X-Y intersections.

Fig. 26

Fig. 27

Main Spindle

Dial Gauge

(6pcs.)

Mounting Bolt

Fig. 28

During transportation, storage or installation, the grease inside the bearings will settle. If the spindle is suddenly

run at high-speed, the grease will be ejected from the bearings, causing excessive heat that will cause bearing

damage. After installation, repair, initial operation, or long periods of non operation, please follow the break-in

procedure detailed in Table 2.

Tool

12

14

Chuck Nut

Spindle Shaft

Loosen

①

Remove the tool according to the section

" 7. CHANGING THE TOOL" procedure

above and remove chuck nut assembly.

(Fig. 16)

②

The collet chuck and chuck nut are

secured by a groove in the collet chuck

and a

À

ange in the chuck nut. To remove

the collet chuck hold the chuck nut in one

hand and push diagonally down on the

collet chuck. The collet chuck should be

released (Fig. 17).

③

To install the collet chuck, hold the collet

chuck at a slight angle, and insert it into

the chuck nut (Fig. 18).

Press the collet chuck in the chuck nut by

positioning the collet chuck in the chuck

nut and pressing down on

À

at surface.

(Fig. 17)

Be sure to fully engage the latch inside

the chuck nut into the groove on the collet

chucks outer circumference area (Fig. 19).

Fig. 16

Groove

Latch

Collet Chuck

Chuck Nut

Latch

Collet Chuck

Wrench Seat

Chuck Nut

DOWN

Fig. 18

Fig. 19

8

. REPLACING THE COLLET CHUCK

CAUTION

When installing the collet chuck into the chuck nut, be sure to fully engage the latch inside the

chuck nut to the groove on the collet chucks outer diameter area. In addition, remember that if the

collet chuck is attached without being engaged with the latch of the chuck nut, the collet chuck

cannot be removed and this may cause damage to the collet chuck or the spindle.

Fig. 17

9

. INSTALLATION INTO THE MACHINE

DANGER

Do not rotate the machining center's main spindle

with the HES Brushless Motor Spindle installed.

Rotating the machining center's main spindle with

the HES Brushless Motor Spindle installed

can cause the motor cord to become tangled and

pull the control unit off it is mounting. This may

cause lead to a big accident.

WARNING

Whenever installing a Brushless Motor Spindle to a

¿

xed base, ensure that the

¿

xed base is grounded

in order to avoid risk of an electric shock.

CAUTION

・

When not using the HES Brushless Motor Spindle

please replace the Electric Connector Cap and air

cap to protect the connectors from contaminants

with HES Brushless Motor Spindle body. And reset

the plug cap for motor cord to motor cord.

・

Check that the Motor Cord Connector, Air Hose

and Emergency Connector have been tightened

properly before operation.

・

DO NOT separate the emergency connector

manually.

It is not a quick disconnect connector. Emergency

System: If the machine's main spindle is rotated

by mistake, the Emergency Connector on the

motor cord will separate. If the hanger for the

Emergency Connector is too loose the Emergency

Connector can slip out of position during high

speed rotation and cause the Emergency System

to malfunction.

Please check the integrity of the Emergency

Connector and suspension prior to use.

10

. CONNECTING TO THE CONTROLLER

11

. THE HES BRUSHLESS MOTOR SPINDLE CENTERING ALIGNMENT

CAUTION

It is important to align the HES centerline to the machining center's centerline prior to using the

HES Brushless Motor Spindle. The HES Brushless Motor Spindle and taper housing are precision

machined to the exacting tolerances of the applicable standard for each taper. However, since no

tolerance is +0, - 0 it could be dif

¿

cult to initially achieve perfect centerline alignment just by hand

loading the spindle. Please follow the steps below to ensure proper centerline alignment.

HES

12

. BREAK-IN PROCEDURE

Steps

1

2

3

4

5

Rotation Speed (min

-1

) (rpm)

12,000

24,000

32,000

40,000

50,000

Rotation Time (min)

15

10

10

10

10

Items to Check

No Abnormal

Noises.

The spindle housing temperature during the break-in process should

not exceed 20 degrees C (36 degrees F) above ambient temperature.

Should the spindle exceed this limit, rest the spindle for at least 20

minutes and re-start the break in procedure from the beginning. If

the housing temperature rises again and exceeds 20 degrees C (36

degrees F) above ambient temperature, check the spindle and motor

for proper installation.

Table 2.

Trouble

Cause

Inspection / Corrective Action

Motor does not run.

Power is not supplied.

・

Make sure to turn ON the Main Power Switch on

the front (rear) of the CONTROLLER.

・

Insert the power cord plug correctly into the Main

Power Inlet with Power Supply Fuses of the

CONTROLLER.

・

Check if a fuse is blown.

Motor Cord Plug is not connected to

the Motor, CONTROLLER.

Connect the Motor Cord plug correctly to the Motor

and CONTROLLER.

Control Button (CTRL) is set to

Manual mode but trying to start

with an External Command Signal

through Input / Output Connector A.

Start with the Start / Stop Button (START/STOP),

or set the Control Button (CTLR) on the Control

Panel to Auto mode.

Control Button (CTRL) is set to Auto

mode but trying to manually start

with the Start Button (START/STOP)

on the Control Panel.

Start with an External Command Signal or set the

Control Button on the Control Panel to Manual

mode.

Emergency Stop Signal on External

Input / Output Connector B is OFF

(Open).

Check the setting of parameter

.

An Error has occurred.

(Error LED is lit.)

Check and correct the source of the Error Code.

Low air pressure.

Adjust to the air pressure 0.25 ~ 0.3MPa.

Can not set the

increase or decrease

of the Motor Rotation

Speed.

Motor Fixed Speed is set in

parameter. Turn this Parameter OFF

to allow rotational speed changes.

Release parameter

.

Can not set the

motor speed to its

maximum allowable

speed.

Either the required speed value is

higher than the maximum rotation

speed of the motor, or the upper

limit of the rotational speed has

been set in parameter

.

Set the Maximum Rotation Speed to a value less

than the Motor Rotation Speed set in Parameter

.

Air Input Monitoring Override is set

in the

parameterto ON and the

motor's maximum speed has been

limited to 30,000 min

-1

(rpm).

Check the setting of parameter

.

A blinking dot appears

on Digital Speed

Indicator. Cannot set

the desired rotation

speed.

Gear Ratio is set to a value other

than "1.0 ".

Check the setting of Gear Ratio.

< CONTROLLER or Motor >

13

. TROUBLESHOOTING

If a problem or concern occur, please check the following items prior to consulting your dealer.

Refer to the E3000 CONTROLLER Operation Manual.

Trouble

Cause

Inspection / Corrective Action

Spindle does not

rotate or rotate

smoothly.

The spindles ball bearings have

been damaged.

Replace the ball bearings.

(Return to NAKANISHI dealer service.)

The motor has been damaged.

Replace the motor.

(Return to NAKANISHI dealer service.)

Overheating during

rotation.

Cutting debris has contaminated the

ball bearings, and the ball bearings

are damaged.

Replace the ball bearings.

(Return to NAKANISHI dealer service.)

Abnormal vibration or

noise during rotation.

The tool shank is bent.

Replace the tool.

Cutting debris has contaminated the

ball bearing.

Replace the ball bearings.

(Return to NAKANISHI dealer service.)

The spindles ball bearings have

been damaged.

Tool slippage.

Collet chuck or chuck nut are not

correctly installed.

Check and clean the collet chuck and chuck nut.

Reinstall the collet chuck and chuck nut.

The collet chuck and the chuck nut

are worn.

Replace the collet chuck and chuck nut.

High run-out.

The tool is bent.

Change the tool.

Chuck nut is not correctly installed.

Secure the collet chuck and the chuck nut correctly.

The collet chuck and the chuck nut

are worn.

Replace the collet chuck and the chuck nut.

Inside of the spindle is worn.

Replace the spindle shaft.

(Return to NAKANISHI dealer service.)

Contaminants inside the collet

chuck and the chuck nut or the

spindle.

Clean the collet chuck, chuck nut and the inside

of the taper and spindle.

The spindle ball bearings has been

damaged.

Replace the ball bearings.

(Return to NAKANISHI dealer service.)

< Spindle >

14

. DISPOSAL OF THE BRUSHLESS MOTOR SPINDLE

When disposal of a Brushless Motor Spindle is necessary, follow the instructions from your local government

agency for proper disposal of industrial components.

Contents are subject to change without notice.

7

. CHANGING THE TOOL

①

Set the provided 12mm wrench on the spindle.

②

Place the provided 14mm wrench on the chuck

nut and turn it counterclockwise to loosen the

collet chuck and remove the tool. (The

¿

rst turn will

loosen the chuck nut, but the tool will not release

and turning will become stiff. Keep turning through

the stiffness and the collet chuck will open.)

③

Clean the collet chuck and chuck nut, then insert

the new tool and tighten the collet chuck by turning

clockwise. Do not overtighten.

CAUTION

Do not tighten the collet chuck without inserting a tool or dummy bur, as this will damage the

collet chuck, spindle or chuck nut, causing dif

¿

culty removing the collet chuck.

RECOMMENDATION

Please set the cutting tools to minimize the overhang amount. 13mm is the maximum amount of

overhang to maintain high accuracy and safety.

14

12

Loosen

14

12

Tighten

Tool

Chuck Nut

Spindle Shaft

Fig. 15

⑦

Installation of the provided lock bar

Screw the lock bar into the tapped hole on the spindle

housing as shown in Fig. 24

CAUTION

The lock bar is not intended to stop the main

spindle from rotating ; it is only intended to be

used as a precautionary measure. If it is not

needed, it does not need to be installed.

CAUTION

・

If the Emergency Connector is separated, check

the motor cord and air hose for damage, Ieaks,

rips, torn insulation or any other damage before

reconnecting the Emergency Connector. If the

Air Emergency Connector is separated, you

may reconnect using a small dab of Super Glue

to reattach it. Check air system for leaks and if

everything checks ok you can proceed with use.

If problems exist in either the Air Emergency

Connector or the Motor Cord Emergency

Connector please send the unit to NAKANISHI

for service. Do not disconnect the Air Emergency

connector expect in an emergency.

2014.09.20 002