22

Trouble Shooting

Sleeping/rest mode: Battery indicator flashes every 5 seconds indicates machine has been idle for more than 20 minutes. V

ario functions disabled cycle key switch!

Number of bars flashing on display

Fault

Possible Cause

Ef

fect on Product

Investigate the Following

Action Required

If Fault

Persists.

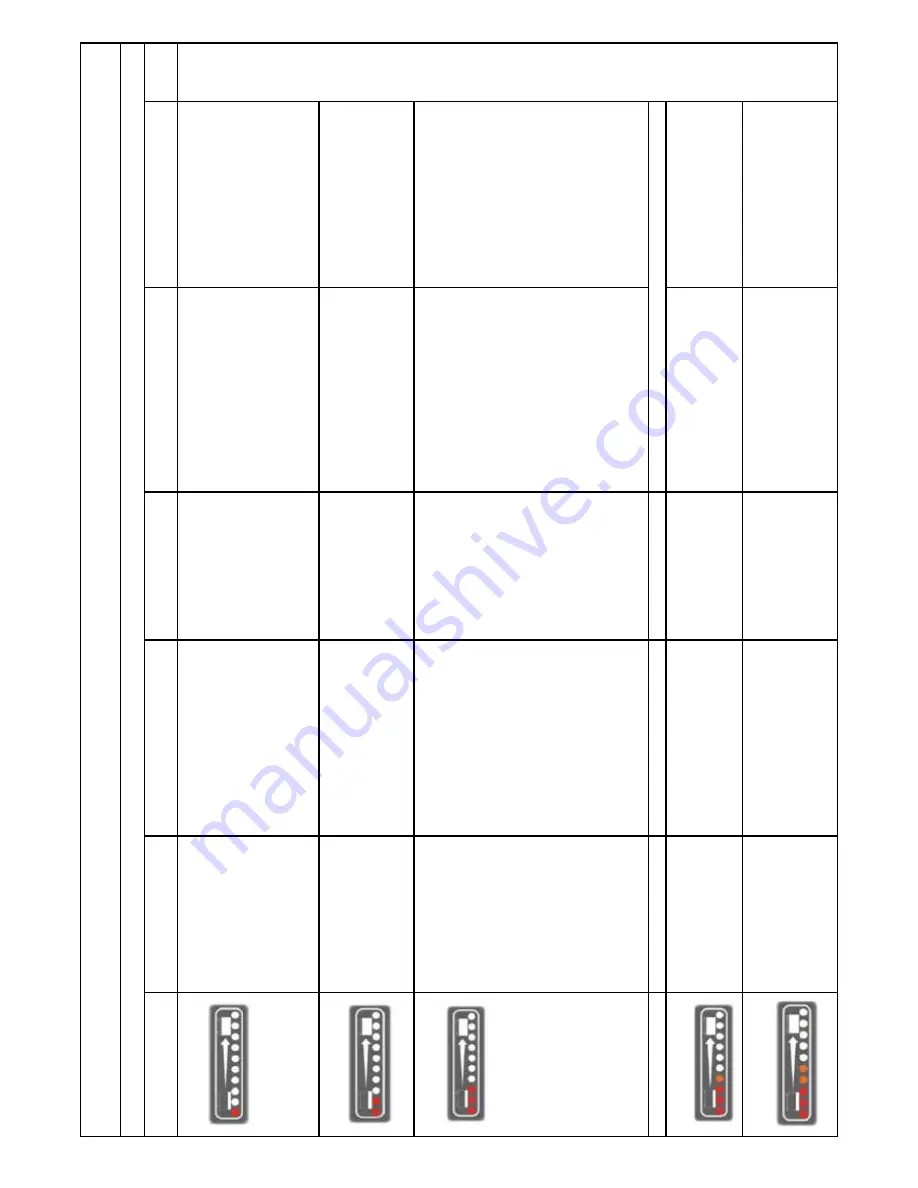

* 1 Bar flashes continuously

* Batteries voltage low

.

* Batteries not been charged.

* Possible bad connection between batteries,

controller

, charger or fuses caused by loose

connections ,

damaged wiring , water ingress.

* Not accepting charge due to faulty battery/cell.

* Charger not functioning.

* Operating time severely reduced

or machine will not operate.

* Check when machine last charged.

* Switch OFF the machine.

* Remove Fuses.

* Check connections to batteries, charger and

fuses for loose wires or screws.

* Check each battery V

oltage individually to detect

defect unit 10.5V min.

* Check battery voltage and charge current.

ensuring charger red fault light is extinguished.

* Charge batteries immediately

.

* T

ighten loose connections and replace dam

-

aged components.

* Replace batteries as required.

* Replace charger

.

* 2 Bars Flash continuously

.

* T

raction drive overload.

* T

raction drive over current trip due to too high

a load.

* T

raction drive is disconnected or has bad con

-

nection due to wiring or

connectors becoming damaged, loose or cor

-

roded due to water ingress.

* Brake engaged no movement.

* Did machine fail on incline. Check traction wheel

free from debris.

* Cycle Key switch to resume normal operation.

If the above fails then: Switch machine of

f.

Check connections and harness between drive

motor and controller

.

* Cycle key switch to resume normal opera

-

tion.

* T

ighten loose connections and replace dam

-

aged components.

3 Bars Flash continuously

.

Brush motor over current trip has

occurred.

Rough floor surface.

Brush motor has failed or is

damaged..

Brush motor bad connection.

* Intermittent brush trip.

* Brush Motor doesn’t run or runs

intermittently

.

* Brush type suitable for floor surface.

“ Cycle Key switch to resume normal operation.

* If the above fails then: Switch of

f machine.

* Check brush motor for damage.

* Check brush motors turn freely

.

* Cycle key switch to resume normal operation.

* If the above fails then.

* Switch machine of

f.

* Check connections and harness between Brush

Motor and controller

.

* Check BRUSH Motor connections block under

-

neath chassis , behind mud guard for loose wires

and loose screws.

* Cycle key switch to resume normal operation.

* Change brush , adjust brush speed and

reduce

pressure by turining adjustment knob anti

-

clockwise.

* Replace ef

fected motor or wiring.

* 4 Bars Flash once with pause.

* System trip.

* System failure.

* Machine will not operate.

* Replace controller

.

* 4 Bars Flash twice with pause.

* Spare Solenoid connection trip.

* System has been incorrectly rewired.

* Machine will not operate.

* Refer to wiring diagram and check the solenoid/

water/detergent pump wiring configuration.

* Rectify wiring fault found.

* 5 Bars flash continuously

.

* V

ac Motor is disconnected, has failed

open circuit, has a bad

connection or water ingress -

temperature trip activated.

* Wiring between V

ac motor and

Controller is damaged, wiring is loose or wiring

connections are loose, possibly wire has come

out of a

connection block - blocked exhaust.

* V

ac motor will not operate.

“ Cycle Key switch to resume normal operation.

* If the above fails then:

* Switch of

f machine.

* Check for loose or damaged wiring and

connections between V

ac motor and controller

.

* Cycle key switch to resume normal operation.

* T

ighten loose connections and replace

damaged components - check exhaust clean

if necessary

.

Contact Service Agent.

Summary of Contents for TTV 678-300T

Page 26: ...26 WD 0359 A18 01 04 2014 ...

Page 27: ...27 ...

Page 29: ...29 Notes ...

Page 30: ...30 Notes ...

Page 31: ...31 Notes ...