32 of 35

Opus Control Wiring and Programming Installation Manual

www.NabcoEntrances.com

P/N C-00139

Rev 3-9-18

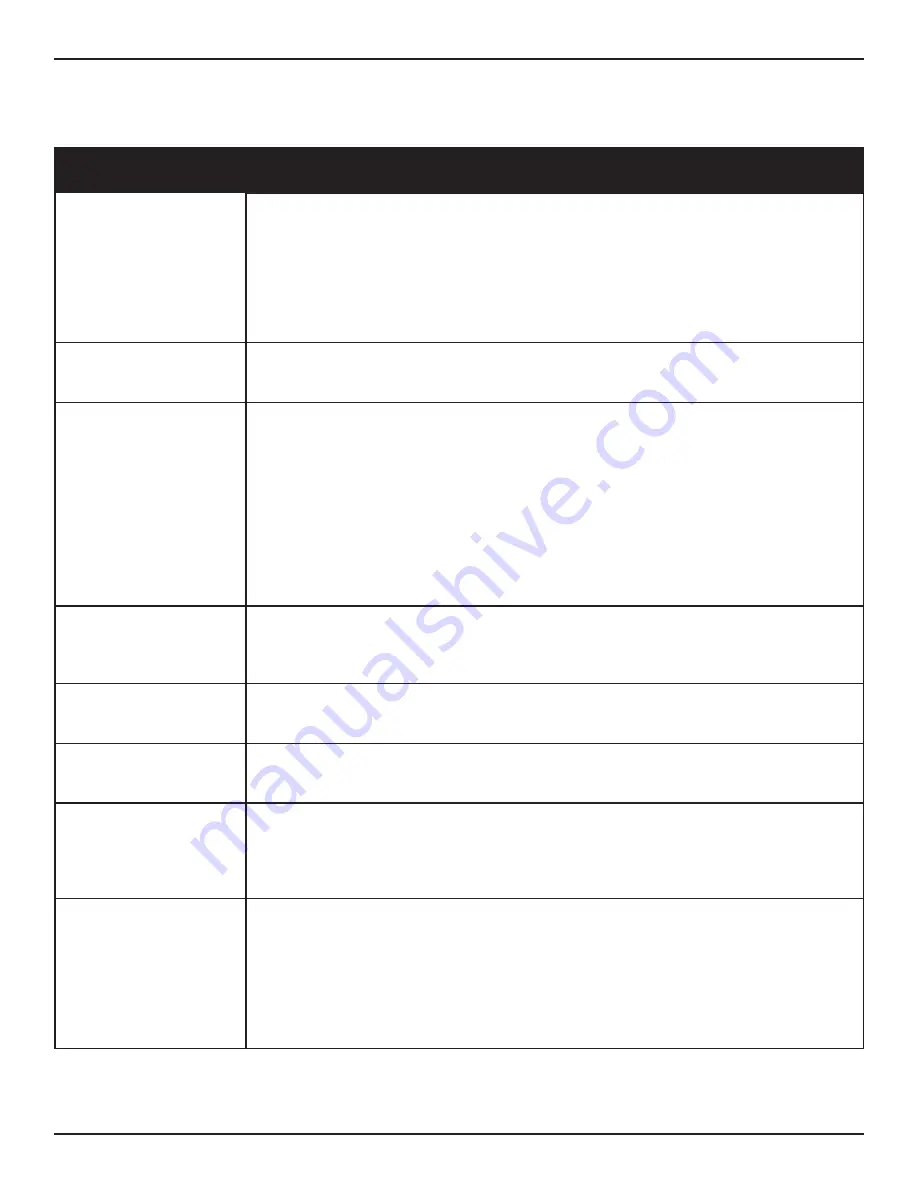

CHAPTER 13: TROUBLESHOOTING

Programming Issues

Problem

Possible Solution

Hard to manually open door

►

►

On outswing only: Check if shoe position and rod length are in accordance with the

dimensions in the manual.

►

►

Except GT710: Reduce the preload on the operator. The Opus is not dependent on preload

since there is no cam and doorposition switches. Maximum preload on GT8500’s should be

one notch on the operator spline to maintain ANSI 156.19

►

►

Software Revision (up to, and including 18)

• Re-enter “0” for “hold closed force” under “optional settings”. The software on early Opus

controls may suggest it’s alreadyset to “0”, but does not act like it. Entering “0” again will fix it.

After manually opening door,

the door stays open

►

►

Software Revision (up to, and including 18)

“Manual Open Function” is set to “No Action” and “Manual Open Sensitivity” is set to “0”. If “No

Action” is desired, change “Manual Open Sensitivity” to anything other than “0”.

Control does not react to

Activation signal

►

►

At the main screen, confirm that “IN” or “EXT” highlights when an activation signal

isapplied. If not, check the wiring or the activation device.

►

►

At the main screen, determine if “BA” is highlighted. If a 4-wire on/off/hold-openswitch is

being used, with a blue wire connected to terminal 8, then “Input BACircuit” (found under

“Input Settings”) must be set to “Normally Closed”. If a 3-wire switch is being used, or no

switch is being used (nothing connected to terminal 8), then “Input BA Circuit” should be

set to “Normally Open”.

►

►

At the main screen, if Status shows “Stopped” while the door is closed, and BA isnot

highlighted, turn off power for at least 4 seconds then turn on again. With the doorstill

closed, status should now show “Fully Closed”.

►

►

Must navigate back to the main screen (as shown at right) for an activation signal to work.

Sim Pair behaves oddly

(Controls may not be

communicating correctly)

►

►

All Revisions

• Do a “copy data” from one control to the other. One control should then indicate “Type 1” on

the main screen, the other should indicate “Type 2”. There is no rule as to which needs to be

which, but they must be different than each other.

Closing functions do not

work when opened manually

►

►

Software Revision (up to 17)

• Closing functions such as (speed, latch-check, power close), change “manual open function”

to something other than “no action”. “stop and close” is usually ideal.

Sim Pair using “Stop & Close”

but results in a “Push & Go”

►

►

Software Revision (up to, and including 20)

• Remove sim-pair harness, set both controls to “single door”, parallel the common terminal

and any input being used between both controls.

Door does not always close

during Latch Check

►

►

Software Revision (up to, and including 19)

►

►

Symptom: When the door is used manually it closes every time. However, when the door is

activated, once in a while it will stop at latch check and not continue to close.

• Increase latch check speed or try increasing operator arm preload (if GT710 - increase spring

tension on hydraulic closer)

Double Egress pairs are not

Synchronizing

►

►

Software Revision (up to, and including 20)

• Remove CANbus cable. Set both Controls as single doors. The activation signal should

be paralleled between both Controls. Safety signals should only be attached to their

corresponding door’s Control.

►

►

Software version is 21

• Be sure both controls are set to “Double Egress”. Safety signals should only be attached to

their corresponding door’s control.

• See also “Sim Pair behaves oddly” located at top of this Table.