3

1.

General information

Thank you for purchasing one of our machines, and we hope that you will be fully satisfied.

This guide provides instructions for the installation, adjustment, operation and

maintenance of the machine B10 ELECTRA in compliance with valid safety standards.

The information and data contained in this document subject to changes due to

further improvement of machinery. To eliminate any doubts, when differences are

detected, please contact N.KO Machines.

Never perform any operation on the machine before you read the instructions in the

manual and understand them. Major part of accidents that happen in the workplace are

due to the fact that the guidelines and recommendations contained in the manual are not

complied with.

The graphic symbols used in the manual are intended to emphasize the important

information regarding the safety and operation of the machine.

Attention :

Information important for the personal safety of the operating staff.

Important:

Instruction that needs to be observed to ensure the proper function of the machine.

2.

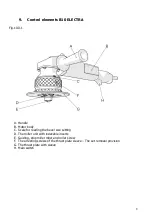

Machine description B10 ELECTRA

Machine B10 ELECTRA is designed solely for the activities below:

B10 ELECTRA is designed solely for bevelling and fetch fettling of metal materials in the

workshop or in the production hall.

This includes manual and manually managed machine. The main feature of the machine

is the ability to machine flat and shaped workpieces, openings, and tubes. The

machining angle can be changed by replacing the milling head. B10 ELECTRA can

perform also the workpiece edge rounding. This application also requires a special tool,

see the text below.

Use the machine in the environment protected from rain, snow, and other adverse

weather conditions.