VJ-1608 Hybrid INSTALLATION MANUAL

VJ1608HYE-I-00

4

1

3

2

1

2

2

1

2

2

1

2

1

2

2

1

2

3

1

2

3

1

1

3

2

1

2

1

4 Installation

Procedures and environment for installing this product

are explained.

4.1 Installation environment

Install this product to the appropriate place with refer-

ence to the following.

Do not install the printer in the follow-

ing places where there is a possibility

that the printer may be damaged or

might fall or be fallen by chance.

On a shaky stand

Slanting location

Places where vibration of other machines

etc. is transmitted.

Do not stamp on the printer or do not

place heavy things on top of it. The

printer may be damaged or might fall

or be fallen by chance.

Cover the printer with blanket and cloth

like tablecloth and do not close the vent.

If the vent is closed, the printer could

accumulate heat inside and may cause

fire.

Do not install the printer in a location

that has high humidity or is dusty.

It could lead to electric shock and fire.

4.1.1 Installation environmental condition

Select an installation location in accordance with the

table below.

For temperature and humidity, avoid locations

such as the following. There is a possibility that

the print quality will be affected.

Places where temperature or humidity may

rapidly change, even though within the required

conditions.

Places that receive direct sunlight, increased illu-

mination or direct air, for example from an air

conditioner.

To keep the temperature and humidity constant, in-

stall this product in a location where the air condi-

tion is adjustable.

(Cont'd)

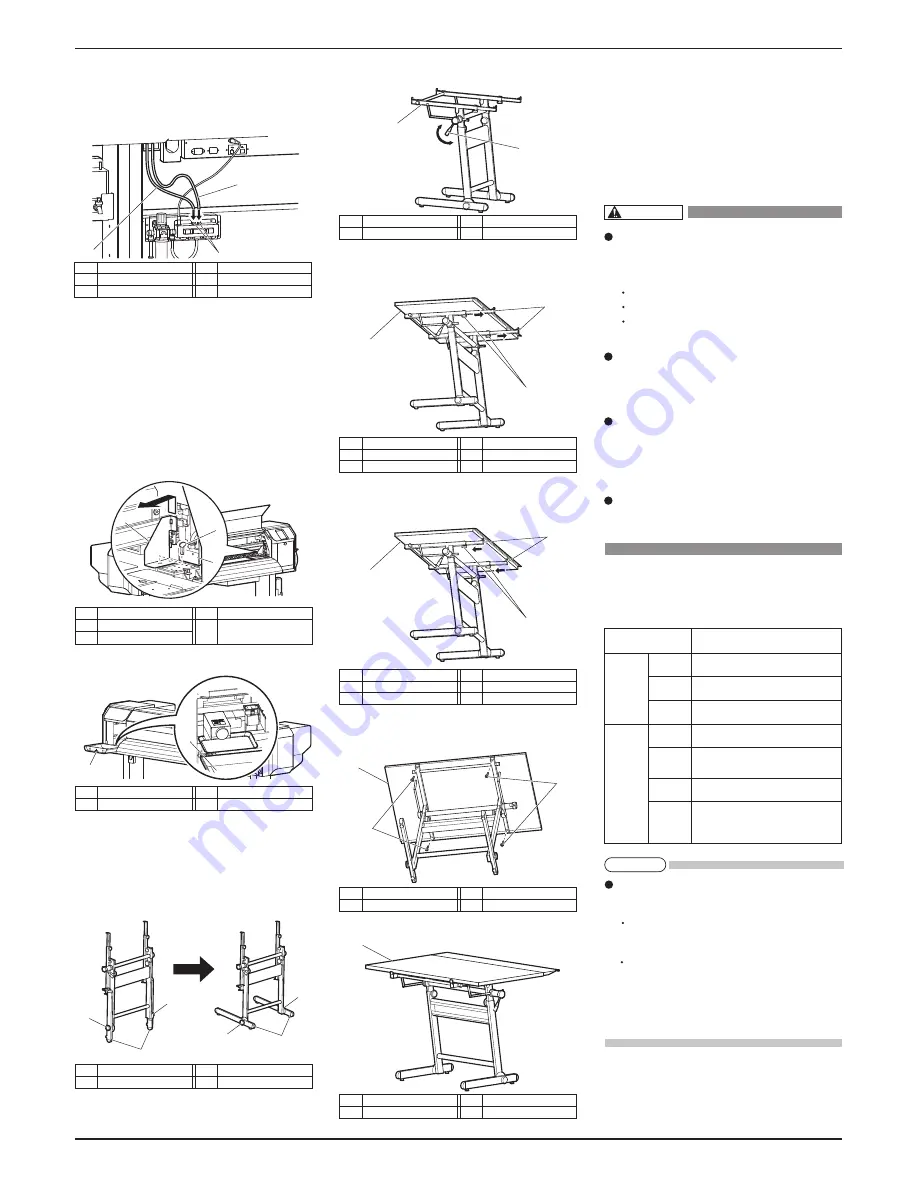

3. Looking at the rear of the printer, attach the short

air tube to the left side of the solenoid valve unit

and the long air tube to the right side of the sole-

noid valve unit.

3.4 Detaching fastening materials

This printer has fastening materials in the place shown

below.

Detach all protective materials in accordance with the

following steps.

1. Remove all tapes from each cover.

2. Open the front cover, then remove a screw from

the head unit fastening material (metal plate) and

remove the material.

3. Open the left maintenance cover, then place the tray.

3.5 Assembling the media-feed table

Follow the procedure below to assemble the Media-

feed table.

1. Loosen the knobs fastening the legs and set the

legs as shown in the illustration.

2. Loosen the angle lever and set the Media-feed table

base so that it is horizontal.

3. Loosen the knobs on the base and extend the draft-

ing board supports to be longer than drafting board

R, and place drafting board R on the base.

4. Shorten the drafting board supports against the

drafting board R and tighten the knobs.

5. Fasten drafting board R by using the drafting board

fastening screws.

6. Assemble Media-feed table F in the same manner.

More than 2940 Pa (300 kg/m2)

Power

Specifica-

tion

Environm-

ental

conditions

Floor strength of

installation place

Power

Supply

Frequency

Range

AC 90 V to 132 V / 198 V to 264 V

50/60Hz ± 1Hz

Power

capacity

Change

rate

Operative

condition

Archiving

condition

(Ink filled)

Printing

accuracy

coverage

Main: 8.5 A

Heater: 10.0

A

Temperature: 20 °C to 32 °C

Humidity: 40 % to 60 %, No Condensation

Temperature: 22 °C to 30°C

Humidity: 40 % to 60 %

Temperature: within 2 °C per hour

Humidity: within 5 % per hour

When Sleep Mode is ON:

Temperature: 10 ° C to 40 °C

Humidity: 20 % to 80 % ,

Storage life: four days (32 °C or higher)

No.

Name

1

Head unit

2

Screw

No.

Name

3

Head unit fastening

material (metal plate)

No.

Name

1

Maintenance cover (Left)

No.

Name

2

Tray

No.

Name

1

Legs

No.

Name

2

Knobs

No.

Name

1

Angle lever

No.

Name

2

Media-feed table base

No.

Name

1

Drafting board R

No.

Name

2

Drafting board fastening screws

No.

Name

1

Media-feed table F

No.

Name

1

Solenoid valve unit

2

Short air tube

No.

Name

3

Long air tube

No.

Name

1

Drafting board R

2

Drafting board supports

No.

Name

3

Knobs

No.

Name

1

Drafting board R

2

Drafting board supports

No.

Name

3

Knobs

WARNING

NOTE

All manuals and user guides at all-guides.com