CAUTION

Do not allow water to enter electrical instruments.

3. Lubricate all lubrication points in accordance with section 7.2. Lubrication.

Damaged paint can be touched up after washing. The painted surface can be protected

with a light application of oil, using protective oil intended for the purpose. Entry of

protective oil on rubber and plastic parts should be avoided.

7.3.4. Cleaning the coulter discs

Wear protective goggles and protective gloves when cleaning the discs of the coulters.

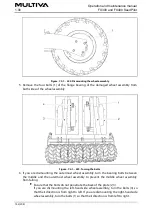

Figure. 7.3.4. - 216. Discs of the coulters

1. Clean the discs (1) of the coulters with a power washer.

Clean the clearance between the scraper and covering wheel as well.

2. Apply protective oil on wear parts to protect them from corrosion.

3. Once the discs are dry, turn each pair of coulter discs a few turns so that the scrapers

remove the dry dirt from the inside of the discs.

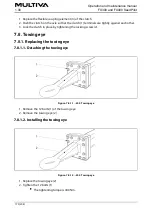

7.3.5. Cleaning the feeder units

Wear protective goggles and protective gloves when cleaning the feeder .

Clean the feeder units at the end of the seeding season.

Operation and maintenance manual

FX300 and FX400 SeedPilot

1.00

164 (208)

Summary of Contents for FX300 SeedPilot

Page 200: ...Hydraulic schematics FX300 and FX400 1 Hydraulic schematics FX300...

Page 201: ...Hydraulic schematics FX300 and FX400 2...

Page 202: ...Hydraulic schematics FX300 and FX400 3 Hydraulic schematics FX400...

Page 203: ...Hydraulic schematics FX300 and FX400 4...

Page 204: ...Electrical schematics FX300 and FX400 1 Electrical schematics...