MAYCO LS300G CONCRETE PUMP • OPERATION MANUAL — REV. #2 (09/09/19) — PAGE 53

TRAILER MAINTENANCE

Periodically check the actuator mounting fasteners for

damage or loosening. Inspect the actuator for worn or

damaged parts. As you are towing your trailer, be aware

of any changes in braking quality. This could be an early

warning of brake or actuator malfunction and requires

immediate attention. Consult a certified brake specialist to

make necessary adjustment or repairs

ADJUSTABLE CHANNEL

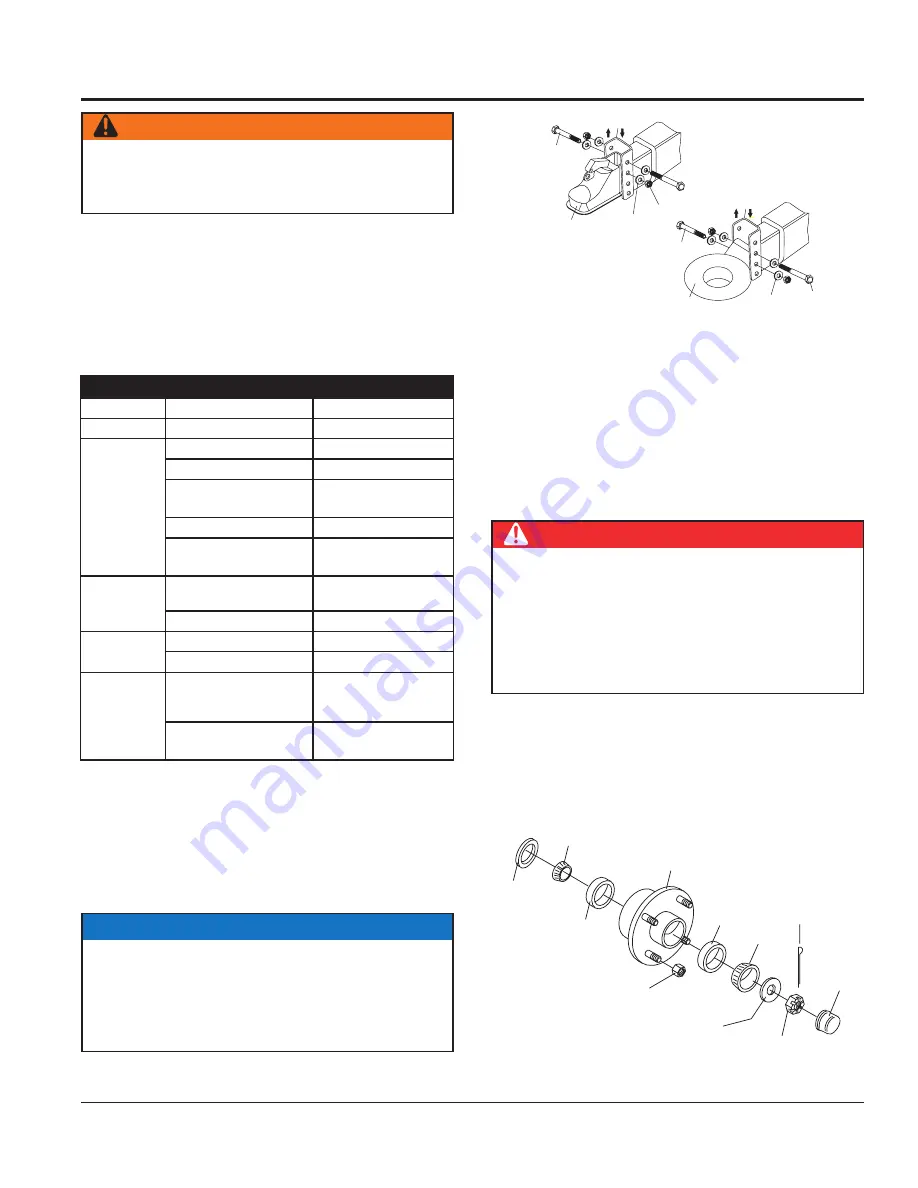

Your trailer may be equipped with an adjustable channel

(Figure 58) that allows the coupler to be raised or lowered

to a desired height. Periodically check the channel bolts

for damage or loosening.

WARNING

Failure to maintain proper fluid level in the actuator

may result in loss of braking action which could cause

severe property damage, injury or death.

Table 8. Hydraulic Brake Troubleshooting

Symptom

Possible Cause

Solution

No Brakes

Brake line broken or kinked?

Repair or replace.

Weak Brakes or

Brakes Pull to

One Side

Brake lining glazed?

Reburnish or replace.

Trailer overloaded?

Correct weight.

Brake drums scored or

grooved?

Machine or replace.

Tire pressure correct?

Inflate all tires equally.

Tires unmatched on the

same axle?

Match tires.

Locking Brakes

Brake components loose,

bent or broken?

Replace components.

Brake drums out-of-round?

Replace.

Noisy Brakes

System lubricated?

Lubricate.

Brake components correct?

Replace and correct.

Dragging

Brakes

Brake lining thickness

incorrect or not adjusted

correctly?

Install new shoes and

linings.

Enough brake fluid or correct

fluid?

Replace rubber parts

fill with DOT 4 fluid.

NOTICE

When replacing channel mounting hardware (nuts,

bolts and washers),

NEVER

substitute substandard

hardware. Pay close attention to

bolt length

and

grade

.

ALWAYS

use manufacturer’s recommended parts

when replacing channel mounting hardware.

Figure 58. Adjustable Channel

Wheel Bearings

Wheel bearings (Figure 58) must be inspected and

lubricated once a year or every 12,000 miles to ensure

safe operation of your trailer.

If trailer wheel bearings are immersed in water, they must

be replaced.

If the trailer has not been used for an extended amount

of time, have the bearings inspected and packed more

frequently, at least every six months and prior to use.

Follow the steps below to disassemble the wheel hub and

service the wheel bearings. See Figure 59.

Figure 59. Wheel Hub Components

2" or 2-5/16" BALL

COUPLER

ADJUSTABLE

CHANNEL

5/8" FLAT

WASHER

5/8" X 11" X 5"

BOLT

5/8"

NYLOC

NUT

ADJUSTABLE

CHANNEL

5/8" FLAT

WASHER

5/8"

NYLOC

NUT

5/8" X 11" X 5"

BOLT

3" PINTLE EYE

RING

DANGER

If trailer wheels are underwater for a long period of

time, wheel bearings may fail. If this is the case, service

wheel bearings immediately.

The possibility exists of the wheels falling off causing

equipment damage and severe bodily harm or even

death!

WHEEL

HUB

BEARING

CUP

BEARING

CUP

BEARING

BEARING

OIL

SEAL

SPINDLE

NUT

SPINDLE

WASHER

COTTER

PIN

DUST

CAP

LUG

NUT

Summary of Contents for MAYCO LS300G

Page 2: ...PAGE 2 MAYCO LS300G CONCRETE PUMP OPERATION MANUAL REV 2 09 09 19 PROPOSITION 65 WARNING...

Page 5: ...MAYCO LS300G CONCRETE PUMP OPERATION MANUAL REV 2 09 09 19 PAGE 5 NOTES...

Page 73: ...MAYCO LS300G CONCRETE PUMP OPERATION MANUAL REV 2 09 09 19 PAGE 73 NOTES...

Page 85: ...MAYCO LS300G CONCRETE PUMP OPERATION MANUAL REV 2 09 09 19 PAGE 85 HYDRAULIC SYSTEM DIAGRAM...