4

MUELLER

®

C1-36 Drilling Machines

Operating Instructions

5

18. Unbolt adapter from valve and

remove adapter and drilling machine

from valve as a unit.

19. Advance boring bar by rotating

feed crank counter-clockwise and

remove hub retaining bolt, (retaining

screw from cutter arbor or retaining

screws from shank of solid drill.)

Remove cut-out section of pipe, shell

cutter, cutter hub or cutter arbor and

pilot drill as a unit.

20. If cutting operation becomes

difficult, follow one of these methods:

a) If cutter has difficulty in cutting,

becomes dull or should stall

after the cut is started, withdraw

the cutter, close valve, remove

machine and sharpen or replace

cutter. Reassemble and proceed

in the regular manner.

b) If cut is well along, release

automatic feed and feed machine

by hand by holding back on

the feed crank at the rear of

the machine a little each half

revolution.

NOTE: Automatic feed should

be used whenever possible.

Automatic feed also provides

the correct tool feed.

14. Continue the cutting operation

until the cutter stops cutting or until

feed indicator reads the amount

shown in the travel chart. (See

pages 7–10 for travel chart).

15. Check completion of cut by

releasing automatic feed and

attempting to advance cutter by

rotating feed crank. If it does not

advance easily, the cut is not

completed and automatic feed

knob must be pushed in to engage

automatic feed for further cutting.

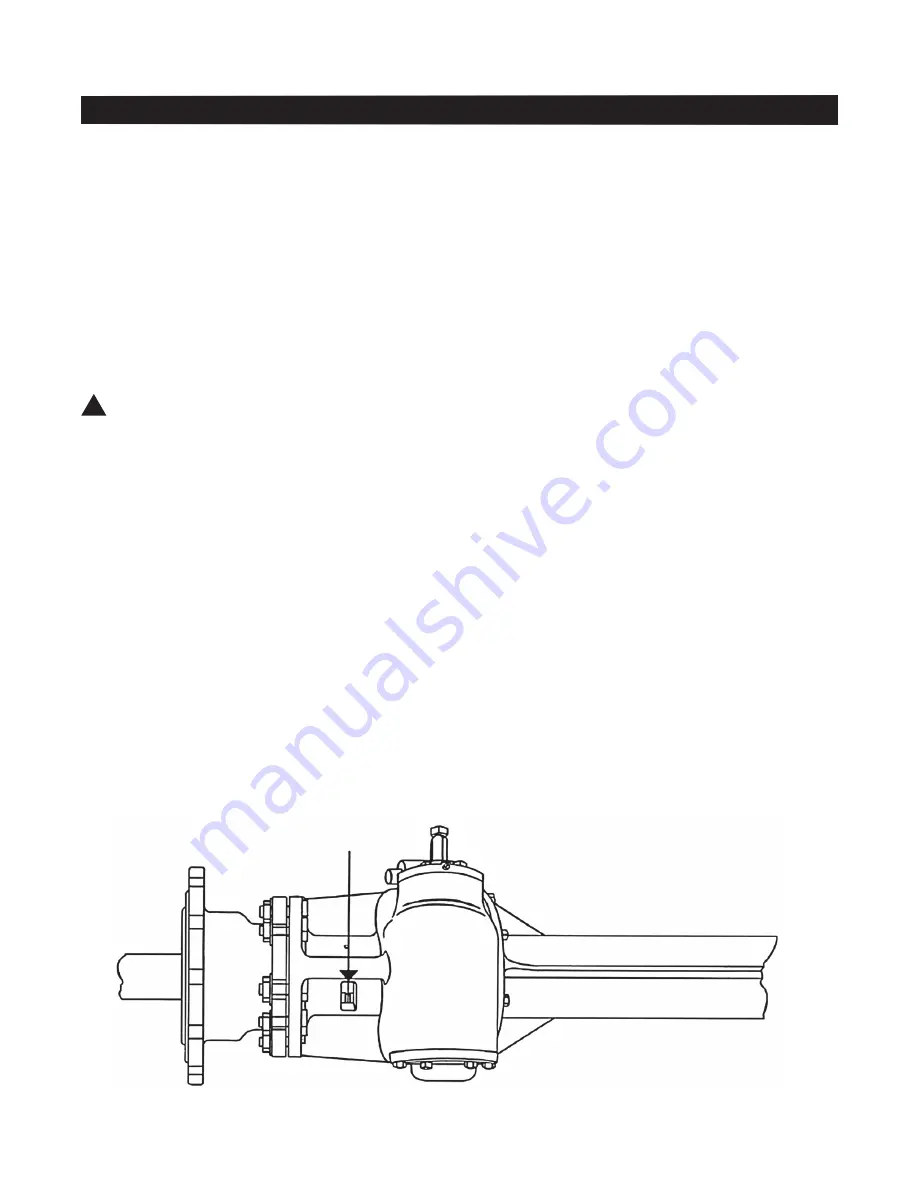

CAUtIoN: stop advancing

the boring bar when the limit line

becomes visible through the drive

box drain hole. see illustration at

bottom of page 5.

Watch the travel carefully when

making a 1

1

/

2

”/DN40 or 2”/DN50

cut. Make sure that the front end

of the boring bar, which is larger in

diameter than the drill, does not hit

the valve seat.

16. When cut is completed, release

automatic feed and withdraw cutter

to its rearmost position by rotating

feed crank clockwise.

17. Close valve securely.

IMpoRtANt: stop advancing

the boring bar if the limit line

becomes visible through drive

box drain hole. It will result in

extensive damage to the machine.

this applies to C1-36 machines

manufactured prior to september

1, 1995. C1-36 machines manu-

factured after september 1,

1995, or rebuilt after this date

and that have “ot” or Model 6

stamped on the name plate have

an overtravel protection feature

which is designed to prevent

damage should the boring bar

be inadvertently advanced too

far. Machines should never be

allowed to overtravel. Feature

does not prevent damage to the

feed screw that could occur as

a result of using dull drills or

cutters.

!

Limit Line