Page 506

Connect the vacuum line to the dis-

charge side of the pump, either in the

discharge opening or the drain tap. A

foot valve is not necessary when this

kind of device is used.

When a vacuum pump is not practical,

a foot valve in the suction inlet can be

used to prevent liquid from running out.

The pump and suction line can then be

filled completely from an outside source.

A vent opening will be necessary during

filling to let air escape. A tight foot valve

will keep the pump constantly primed so

that automatic operation is possible. The

valve should be inspected regularly to

see that it does not develop leaks which

would allow the pump to run dry.

Optional self-priming casings are avail-

able for MTH pumps allowing priming

when a vacuum pump or foot valve is

not practical. Refer to specific literature

for details.

There are four components to the self

primer:

1. A check valve - necessary to main-

tain a vacuum in the suction line as

surging occurs in the pump.

2. An air eliminator - used on the dis-

charge side of the pump to separate

air from liquid so the liquid can be

used again as air is carried through

the pump.

3. A recirculating line - carries liquid

from the air eliminator to the suction.

4. A fluid chamber - used on the inlet

side to provide a supply of fluid to

speed up priming.

Small suction lines are desirable to

minimize priming time.

Using the self priming casing, it is only

necessary to:

1. Open the plugs in both the inlet and

discharge chambers.

2. Pour fluid in one until both are full.

3. Tighten both plugs.

4. Turn on the pump.

Priming time depends on lift, volume of

air in the suction line, and the size of

the regenerative turbine pump used. If

priming time is long and the pump be-

comes warm, refill the priming chambers

with fresh liquid. Most turbine pumps will

pump twenty-six to twenty-eight inches

of mercury vacuum with cold water in

the pump, but have very little capacity

and therefore are not practical at lifts

over twenty-two feet.

The best way to prime a pump and keep

it primed is to use a flooded suction.

While this is not always practical, it does

provide a number of advantages. The

likelihood of pump damage from dry run-

ning is eliminated. Suction lines may be

large, reducing line losses and minimiz-

ing the potential of cavitation damage.

There are no check valves or priming

devices to fail or require maintenance.

Whenever possible, design pumping

systems with flooded suction.

3H Starting

Before starting a pump for the first time,

be sure that all the preceding operations

have been carried out. Proper rotation,

priming, and a free turning pump are

most important.

1. Start the pump with the minimum

possible line restriction.

2. Open discharge valves before press-

ing the starter.

3. Start the pump and let the system

clear of air.

4. Listen for foreign material being car-

ried through the pump.

5. Slowly close necessary valves or oth-

erwise place the pump into service.

6. Listen for indications of undue load or

other sounds indicating problems.

7. Use a clip-on ammeter to check for

a steady load after approximately

fifteen minutes of operation.

3I Stopping

It is best to stop the pump with the

least discharge head possible both for

minimizing strain on components and to

be in low power mode in anticipation of

T31 SERIES

4.

Maintenance

CLOSE COUPLED PUMPS

A.

Seals

B.

Cooling Water

C.

Lubrication

4A Seals

Mechanical seals are used in MTH

Pumps to eliminate the maintenance

that is normally associated with packing

boxes. This does not, however, mean

they can totally be ignored. Check a new

installation for seal leakage.

Maintenance of seals consists primarily

of periodic observation, looking for the

first signs of failure. An occasional drip

that continues to worsen is an indica-

tion that the seal has failed and must be

replaced. Follow the appropriate disas-

sembly/assembly instructions. Always

shut down a pump with failed seals

as soon as possible. Leaky seals are

usually followed by bearing failures and

then possible pump damage as rotating

parts become mis-aligned.

4B Cooling Water

If a heat exchanger is used to supply

cooling water for the seals, check the

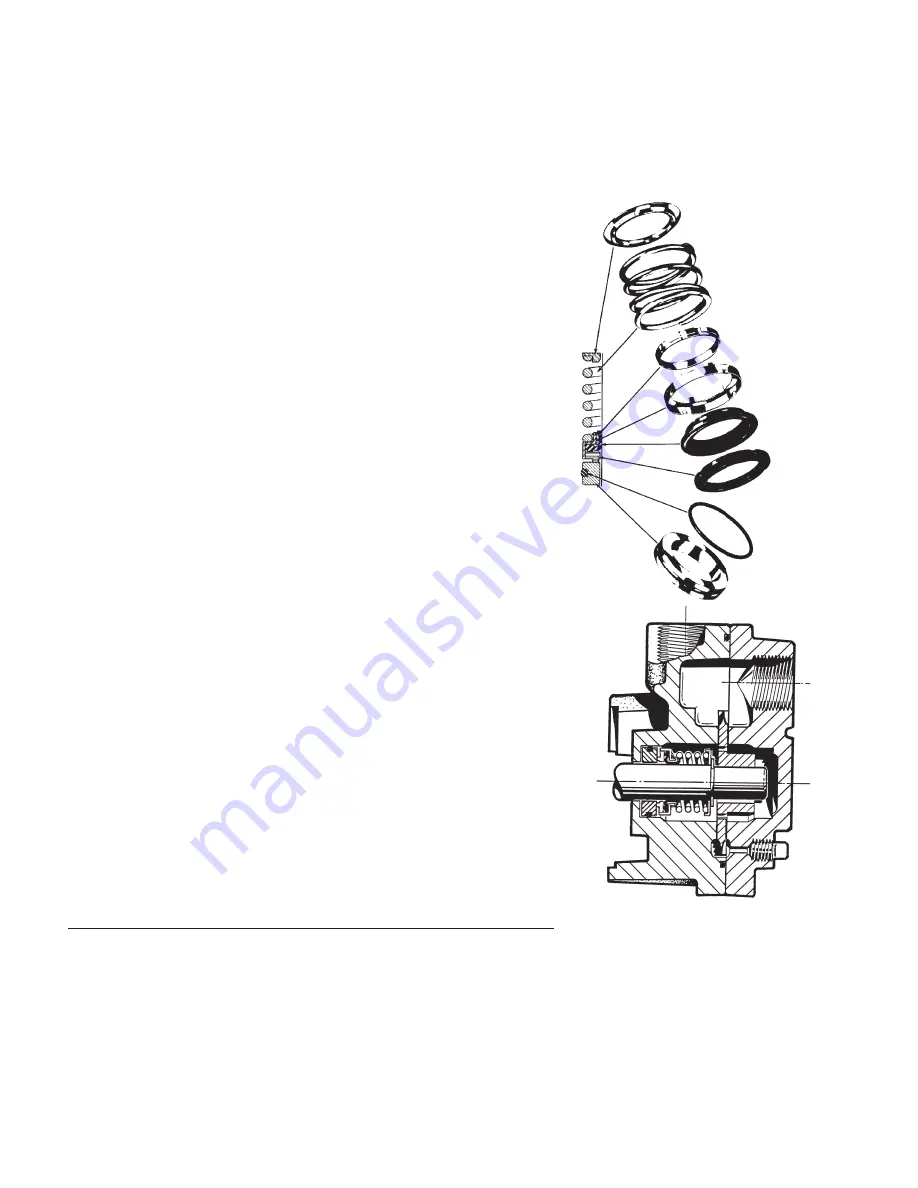

Figure 4-2 Standard Seal Consrtuction

Figure 4-1

Seat

"O" Ring

Washer

Fexible

Diaphragm

Retainer

Drive Ring

Spring

Spring

Holder

restarting. If the pump will be down for

more than a few weeks it is advisable to

drain it. Follow the instructions for long

term storage, Section 1, 1B Storage.

After any prolonged stoppage, turn the

pump over by hand before restarting, to

be sure it is free.