Page 513

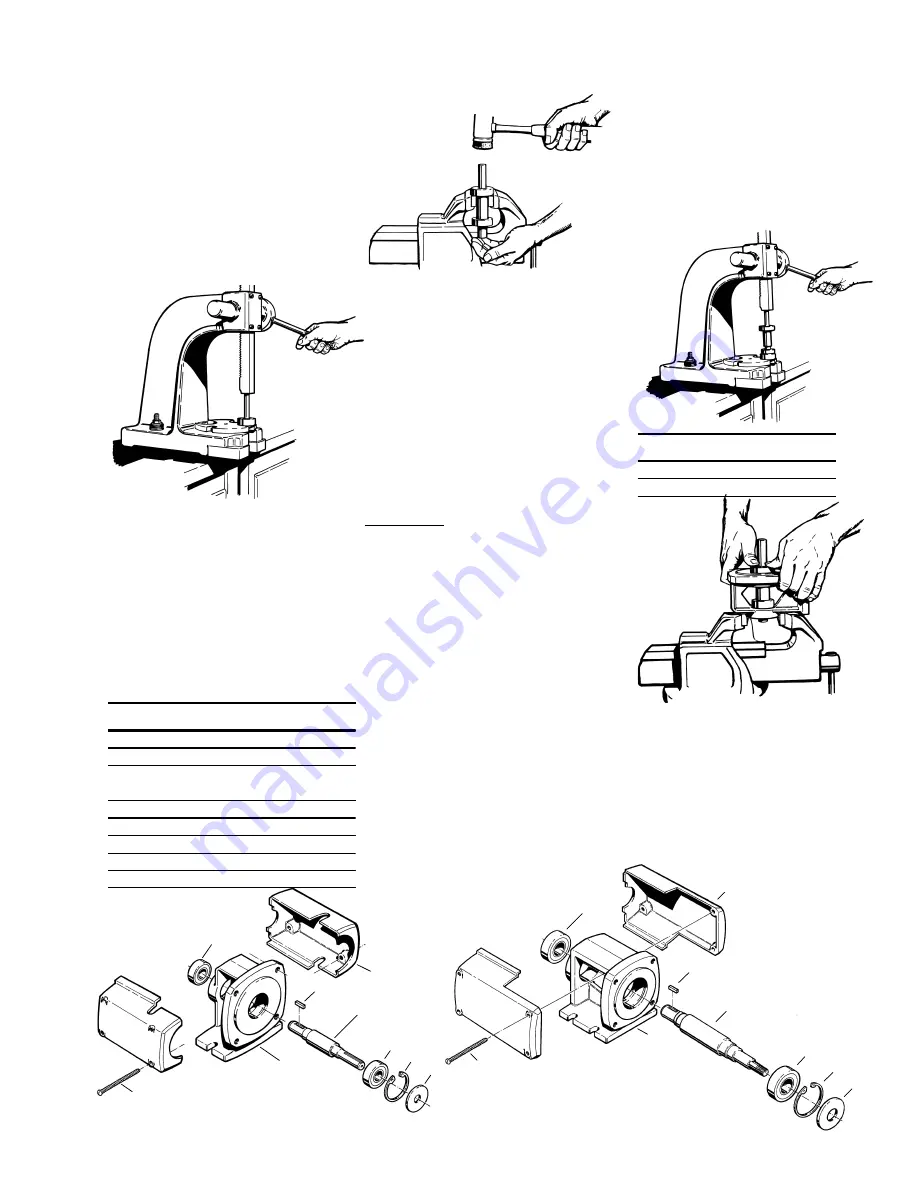

5. Using a plastic or wooden mallet,

gently tap on the end of the shaft

until it slides out of the frame. Both

bearings should come out with the

shaft. Do not use a metal hammer,

severe damage to the shaft will

occur.

6. Using the arbor press, remove the

two (2) bearings from the shaft.

Refer to Figure 4-21. If the inner

race is well supported during this

operation, no damage will be done

to the bearings.

bearing is removed. Refer to Figure 4-

22.

and outside diameter, refer to Chart

1, should be used between the arbor

face plate and the lower bearing to

insure proper installation, and to

prevent bearing damage. The

bearings must seat against the

shoulder for proper alignment. Refer

to Figure 4-23.

*Also refer to Alternate bearing

installation procedures.

30

23

17

24

4

21

3

33

24A

Figure 4-19 P3 Bearing Pedestal

4

P3 & P15 BEARING PEDESTAL

NAME/DESCRIPTION

PART NO. QTY.

Bearing Pedestal

3

1

Snap Ring/Bearing Retainer

4

1

Shaft

17

1

Flinger

21

1

Key Coupling

23

1

Ball Bearing/Inboard

24

1

Ball Bearing/Outboard

24A

1

Coupling Guard/Halves

30

2

Capscrew

33

4

Figure 4-21

If an arbor press is not available, a

bench vise may be substituted using

the following procedure.

1. Remove the pedestal and close the

jaws to approximately 1-1/8" for

model P3 and 1-3/8" for model P15.

2. Place the shaft with either bearing

resting on top of the jaws and gently

tap on the end of the shaft until the

Figure 4-22

3. Repeat step 2 to remove the other

bearing. Good support used on the

inner races will prevent bearing

damage.

4C Inspection of Components

Thoroughly clean all parts. All compo-

nents should be examined for wear and

corrosion. Replace any parts showing

visible wear.

Check to be certain that a press fit still

exists between the shaft and the bearings.

New bearings, or at least cleaned and

regreased bearings, are recommended.

Check the shaft for galling, pitting, and

corrosion. Surface corrosion on the pump

portion of the shaft must be removed so

the seals will slide freely during assembly.

The shaft diameter should be no smaller

than .002" below the nominal fractional

seal sizes. Remove any nicks or burrs

which may have occurred during disas-

sembly. Reclean parts as necessary.

4D Reassembly

All parts should be visually inspected and

cleaned or replaced as outlined in 4C

above. It is recommended that the

bearings be replaced any time the bearing

pedestal is disassembled for service.

1. Using an arbor press, install the

bearings on the shaft prior to installing

the shaft into the pedestal. A steel

“donut” with the proper inside diameter

P3

P30

Inside Diameter

1"

Outside Diameter

2"

Figure 4-23

CHART 1

Figure 4-24

30

23

17

24

33

24A

3

Figure 4-20 P15 Bearing Pedestal

2. Place the pedestal, pump mounting

surface up, in a vise or suitable

fixture and insert the bearing

assembly. It should be possible to

install the shaft assembly with firm

thumb pressure. Refer to Figure 4-

24. If more force is required, the

butt end of a hammer handle or

plastic mallet may be helpful. The

shaft assembly should never be

forced or driven in.