2SHUDWLQJ LQVWUXFWLRQV 0RWRU +RHV

English

7

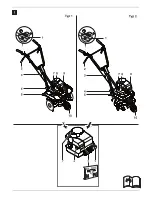

8VERWTSVXEXMSR

1SZMRKXLIQEGLMRI

For manoeuvring or traversing short

stretches.

■

Move the depth gauge/

transportation wheel into the

transport position (Fig.

).

■

Raise the steering handle until the

tiller blades no longer touch the

ground.

■

Move the machine carefully.

8VERWTSVXEXMSR[MXL

E WYMXEFPIZILMGPI

(ERKIVSJMRNYV]

&IJSVIXVERWTSVXEXMSR

r 7[MXGLSJJXLIIRKMRI

r 6IQSZIXLIWTEVOTPYKXIVQMREP

r ;EMXYRXMPXLIIRKMRILEWGSSPIH

HS[R

■

Transport the machine in a

horizontal position in or on a vehicle.

■

Ensure that the machine cannot

roll or slip.

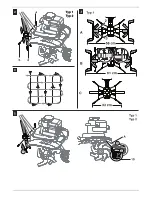

7IVZMGMRKGPIERMRK

(ERKIV

8STVSXIGXEKEMRWXMRNYV]FIJSVIEPP

[SVOSRXLIETTPMERGI

r W[MXGL3**XLIIRKMRI

r [EMXYRXMPEPPQSZMRKTEVXWLEZI

GSQIXSEGSQTPIXIWXSTERH

XLI IRKMRILEWGSSPIHHS[R

r VIQSZIXLIWTEVOTPYKGSRRIGXSV

SRXLIIRKMRIMRSVHIVXSTVIZIRX

XLIIRKMRIJVSQEGGMHIRXEPP]FIMRK

WXEVXIH

r TPIEWISFWIVZIXLIEHHMXMSREP

WEJIX]MRJSVQEXMSRMRXLIIRKMRI

QERYEP

'EYXMSR

8MPXXLIETTPMERGIMRWYGLE[E]XLEX

XLIWTEVOTPYKMWEXXLIXSTWSXLEX

XLIIRKMRIMWRSXHEQEKIHHYIXS

TIXVSPSVSMP

7IVZMGMRK

'EYXMSR

4PIEWISFWIVZIXLIQEMRXIRERGI

MRWXVYGXMSRWMRXLIIRKMRIQERYEP

%X XLIIRHSJXLIKVEWWGYXXMRK

WIEWSRLEZIXLIETTPMERGI

GLIGOIH ERHWIVZMGIHMREWTIGMEPMWX

[SVOWLST

'EYXMSR

)RZMVSRQIRXEPLE^EVHGEYWIH

F] IRKMRISMP

%JXIVGLERKMRKSMPKMZIXLI[EWXI

SMP ]SYLEZIHVEMRIHXSEGIRXVI

EYXLSVMWIHXSHMWTSWISJ[EWXISMP

SV XSERSXLIVHMWTSWEPGSQTER]

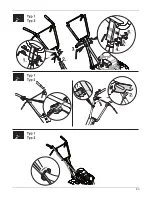

1EMRXIRERGITPER

&IJSVIIEGLYWI

■

Check the oil level, fill up if

necessary.

■

Check screw connections for firm

seating, tighten if necessary.

■

Check the safety devices.

0YFVMGEXMRK

■

Lubricate all moving and rotating

parts with a light oil.

1EMRXIRERGI[SVOSRXLIIRKMRI

■

See Engine instructions.

3RGITIVWIEWSR

■

Have the machine tested and

serviced in a specialist workshop.

!

!

1EMRXIRERGI[SVO

After use

10 h

25 h

50 h

100 h

Each

season

As

required

Clean side shields and hoeing assembly

●

Clean air filter

●

Exchange air filter

●

Change oil

)

●

Grease moving and rotating parts

●

Clean spark plugs

)

●

Have the spark plugs changed

)

●

Clean air-cooling system and exhaust

)

●

●

Check clutch setting, if required have

it re-adjusted

)

●

Have the carburettor setting checked

)

●

Sharpen the hoeing assembly or

exchange it

)

●

Summary of Contents for Tiller

Page 1: ...18 4VSHYGXW OXMIRKIWIPPWGLEJX 7EEVFVµGOIR IVQER 361 23 ...

Page 2: ......

Page 3: ......

Page 4: ......

Page 5: ......

Page 6: ... RKPMWL VER EMW IYXWGL 2IHIVPERHW XEPMERS WTE SP 7ZIRWOE ERWO 2SVWO 7YSQM 4SVXYKYÂW r w ...

Page 7: ... ...

Page 8: ... ...