4

5.

Never run an engine indoors or in a poorly ventilated

area. Engine exhaust contains carbon monoxide, an

odorless and deadly gas.

6.

Do not operate machine while under the influence of

alcohol or drugs.

7.

Muffler and engine become hot and can cause a burn. Do

not touch.

8.

Exercise extreme caution when operating on or crossing

gravel surfaces. Stay alert for hidden hazards or traffic.

9.

Exercise caution when changing direction and while

operating on slopes.

10. Plan your snow-throwing pattern to avoid discharge

towards windows, walls, cars etc. Thus, avoiding

possible property damage or personal injury caused by a

ricochet.

11. Never direct discharge at children, bystanders and pets

or allow anyone in front of the machine.

12. Do not overload machine capacity by attempting to clear

snow at too fast of a rate.

13. Never operate this machine without good visibility or

light. Always be sure of your footing and keep a firm hold

on the handles. Walk, never run.

14. Disengage power to the auger/impeller when

transporting or not in use.

15. Never operate machine at high transport speeds on

slippery surfaces. Look down and behind and use care

when backing up.

16. If the machine should start to vibrate abnormally, stop the

engine, disconnect the spark plug wire and ground it

against the engine. Inspect thoroughly for damage.

Repair any damage before starting and operating.

17. Disengage all clutch levers and stop engine before you

leave the operating position (behind the handles). Wait

until the auger/impeller comes to a complete stop before

unclogging the discharge chute, making any

adjustments, or inspections.

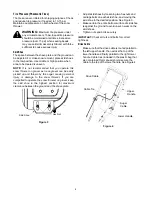

18. Never put your hand in the discharge or collector

openings. Always use the chute clean-out tool provided

to unclog the discharge opening. Do not unclog

discharge chute while engine is running. Shut off engine

and remain behind handles until all moving parts have

stopped before unclogging.

19. Use only attachments and accessories approved by the

manufacturer (e.g. wheel weights, tire chains, cabs etc.).

20. If situations occur which are not covered in this manual,

use care and good judgment. Contact your dealer or call

1-800-800-7310 for assistance and the name of your

nearest servicing dealer.

Maintenance & Storage

1.

Never tamper with safety devices. Check their proper

operation regularly. Refer to the maintenance and

adjustment sections of this manual.

2.

Before cleaning, repairing, or inspecting machine

disengage all levers and stop the engine. Wait until the

auger/impeller come to a complete stop. Disconnect the

spark plug wire and ground against the engine to prevent

unintended starting.

3.

Check bolts and screws for proper tightness at frequent

intervals to keep the machine in safe working condition.

Also, visually inspect machine for any damage.

4.

Do not change the engine governor setting or over-speed

the engine. The governor controls the maximum safe

operating speed of the engine.

5.

Snow thrower shave plates and skid shoes are subject to

wear and damage. For your safety protection, frequently

check all components and replace with original

equipment manufacturer’s (OEM) parts only. “Use of

parts which do not meet the original equipment

specifications may lead to improper performance and

compromise safety!”

6.

Check controls periodically to verify they engage and

disengage properly and adjust, if necessary. Refer to the

adjustment section in this operator’s manual for

instructions.

7.

Maintain or replace safety and instruction labels, as

necessary.

8.

Observe proper disposal laws and regulations for gas,

oil, etc. to protect the environment.

9.

Prior to storing, run machine a few minutes to clear snow

from machine and prevent freeze up of auger/impeller.

10. Never store the machine or fuel container inside where

there is an open flame, spark or pilot light such as a water

heater, furnace, clothes dryer etc.

11. Always refer to the operator’s manual for proper

instructions on off-season storage.

Your Responsibility

Restrict the use of this power machine to persons who

read, understand and follow the warnings and

instructions in this manual and on the machine. The

safety labels are shown below for your reference.

Do not modify engine

To avoid serious injury or death, do not modify engine in any

way. Tampering with the governor setting can lead to a

runaway engine and cause it to operate at unsafe speeds.

Never tamper with factory setting of engine governor.

Notice regarding Emissions

Engines which are certified to comply with California and

federal EPA emission regulations for SORE (Small Off Road

Equipment) are certified to operate on regular unleaded

gasoline, and may include the following emission control

systems: Engine Modification (EM) and Three Way Catalyst

(TWC) if so equipped.