1.

Page 30

mrcool.com

Refrigerant Piping Connection

IMPORTANT:

2

.

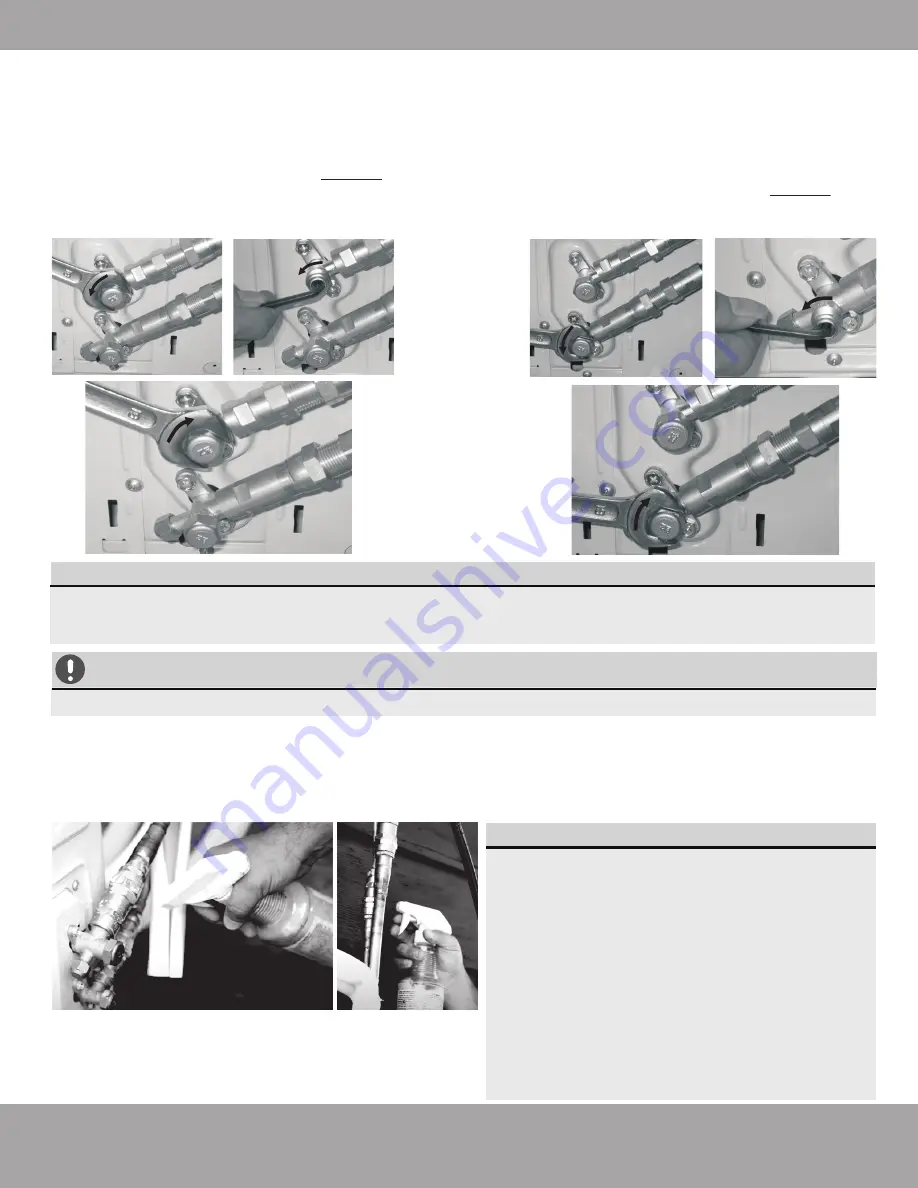

Using the images below as a guide, remove the cover

on the top valve, using a 19 mm open-ended wrench

or a crescent (adjustable-type) wrench. Then, insert a

5 mm Allen key and open the valve by turning it

counter-clockwise as far as it will go.

DO NOT

force it.

The valve is now open. Screw the cover back onto the

top valve and tighten it well to ensure that it is

properly sealed.

Using the images below as a guide, repeat the same

process for the bottom valve. Remove the cover on

the bottom valve, using a 19 mm open-ended wrench

or a crescent (adjustable-type) wrench. Then, insert a

5 mm Allen key and open the valve by turning it

counter-clockwise as far as it will go.

DO NOT

force it.

Screw the cover back onto the bottom valve and

tighten it well to ensure that it is properly sealed.

You will be asked to check for leaks at the

piping connections multiple times

throughout the following steps of the

installation, because the pressures within

the lines will change once the unit is turned

on and this could reveal leaks not present

during the initial check. These are imperative

to make sure your connections are not

allowing refrigerant to escape the system.

When checking for leaks, if any bubbles form,

it indicates the system has a leak and the

screw connector needs to be retightened. For

more information about checking for leaks,

please refer to the Electrical and Gas Leak

Checks section of the manual.

If the valves are not fully opened, it could cause the system to malfunction and suffer damage.

CAUTION

The conical ring on the valve and the seat within the caps have an important function of sealing

the valve. Ensure that you do not damage the cone and you keep the cap free of dust and dirt

while performing these steps.

IMPORTANT:

Step 5: Opening the refrigerant valves of the outdoor unit

After completing steps 1 and 2, you will now need to check all of the piping connections (at indoor unit and

outdoor unit) for leaks. You can do this by using leak detection spray or applying a soapy water solution (liquid

detergent/water mixture) to the connection via a spray bottle or brush. If any bubbles begin to form, that

indicates there is a leak, and the connection needs to be retightened. Tighten the connection and recheck it

for leaks. Refer to

Electrical and Gas Leaks Checks

section of this manual for more information.

3.