time, in this way, you could reduce or stop the overshoot temperature.

4. Different articles with different humidity required different drying time. If longer drying time

required and the vacuum degree reduced, exhaust air and make vacuum circumstances again and

vacuum pump and then open the vacuum valve.

5. After finish drying, close the power firstly, open the return-air valve, make the air in the oven not

in vacuum condition, open the oven door and take the articles out. (In vacuum conditions, the rubber

ring and glass door absorbed tightly, not easy to open the oven door, after some time, open it easily).

6. In vacuum condition, the control temperature could not lower than 50

℃

. If it is lower than

50

℃

,the value measured by standard thermometer is different with the display value of meter, that

is normal. It could not affect the temperature control and precision when the temperature is higher

than 50

℃

.

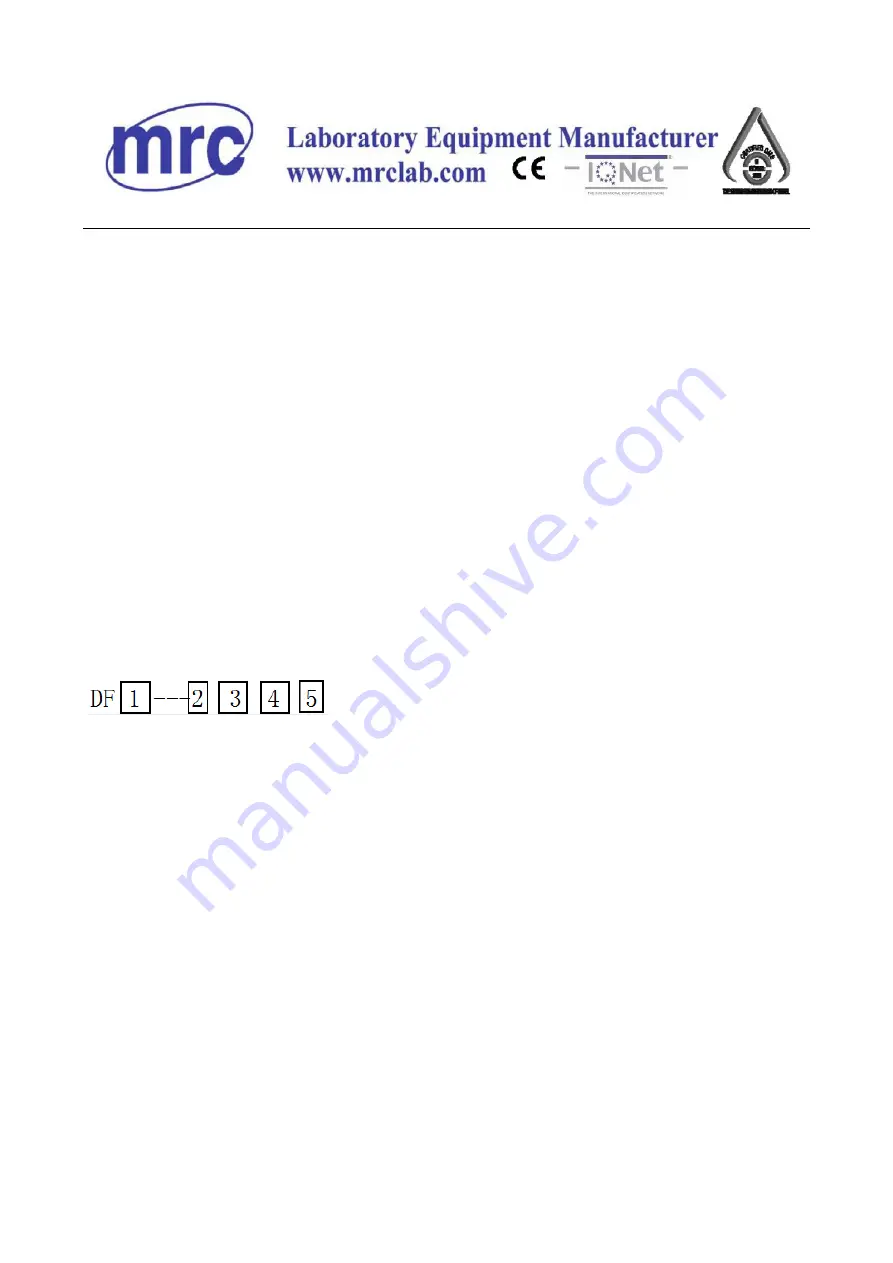

7.Display instructions

1.Product code

(1) Panel size(mm)

D:72*72 G:48*48 E:48*96 A:96*96 W:80*160

(2) 7 Degree of intelligence

(3) Output mode selection

4: Relay output

5: Solid state relay output

6: Phase shift trigger pulse output

7: Zero-crossing trigger SCR output

8: Zero-crossing trigger pulse signal output

9: 0-10mA 4-20mA continuous current output

10: Phase shift continuous output

11: 0-5V 0-12V On-off output

(4) Alarm selection

0: no alarm

1: relay alarm

2: buzzer alarm

(5) Model input type selection

1: K.E.S.B and other thermocouple input

2: CU50.PT100

3:

0-10mA 0-5V linear voltage output