DCA-180SSJU — OPERATION AND PARTS MANUAL — REV. #3 (02/01/10) — PAGE 61

1

MAINTENANCE (TRAILER)

Hydraulic Surge Brakes

Hydraulic surge brakes (Figure 61) should not require any

special attention with the exception of routine maintenance

such as shoe and lining replacement. Brake lines should be

periodically checked for cracks, kinks, or blockage.

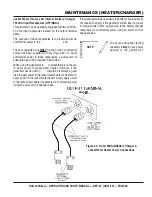

Figure 61. Hydraulic Brake Components

Brakes

Trailer brakes should be inspected the

of

operation. This will allow the brake shoes and drums to seat

properly. After the first 200 mile interval, inspect the brakes

. If driving over rough terrain, inspect the

brakes more frequently.

Figure 61 displays the major hydraulic surge brake

components that will require inspection and maintenance.

Please inspect these components as required using steps 1

through 8 and Table 15 as listed below:

Brake Adjustment

1. Place the trailer on jack stands. Make sure the jack stands

are placed on secure level ground.

2. Check the wheel and drum for free rotation.

3. Remove the adjusting hole cover from the adjusting slot

at the bottom brake backing plate.

4. With a screwdriver or standard adjusting tool, rotate the

star wheel of the adjuster assembly to expand the brake

shoes.

5. Adjust the brake shoes outward until the pressure of the

lining against the wheel drum makes the wheel difficult

to turn.

6. Adjust, rotate the star wheel in the opposite direction

until the wheel rotates freely with slight lining drag.

7. Replace the adjusting hole cover and lower the trailer to

the ground.

8. Repeat steps 1 through 7 on the remaining brakes.

Actuator

Hydraulic surge braking requires the installation of an

actuator at the tongue of the trailer. Remember the

or

of the trailer toward the tow vehicle automatically

synchronizes the trailer brakes with the tow vehicle brakes.

As the trailer pushes against the tow vehicle the actuator

telescopes together and applies force to the master cylinder,

supplying hydraulic pressure to the trailer brakes.

Periodically check and test the surge “

” to make

sure that it is functioning correctly. Never use an undersize

actuator.

Table 13. Hydraulic Brake Troubleshooting

Symptom

Possible Cause

Solution

No Brakes

Brake line broken or kinked?

Repair or replace.

Weak Brakes or Brakes Pull to

One Side

Brake lining glazed?

Reburnish or replace.

Trailer overloaded?

Correct weight.

Brake drums scored or grooved?

Machine or replace.

Tire pressure correct?

Inflate all tires equally.

Tires unmatched on the same axle?

Match tires.

Locking Brakes

Brake components loose, bent or broken?

Replace components.

Brake drums out-of-round?

Replace.

Noisy Brakes

System lubricated?

Lubricate.

Brake components correct?

Replace and correct.

Dragging Brakes

Brake lining thickness incorrect or not

adjusted correctly?

Install new shoes and

linings.

Enough brake fluid or correct fluid?

Replace rubber parts

fill with dot 4 fluid.

Summary of Contents for DCA180SSJU WHISPERWATT SERIES

Page 2: ...PAGE 2 DCA 180SSJU OPERATION AND PARTS MANUAL REV 3 02 01 10 PROPOSITION 65 WARNING ...

Page 69: ...DCA 180SSJU OPERATION AND PARTS MANUAL REV 3 02 01 10 PAGE 69 1 NOTES ...

Page 72: ...PAGE 72 DCA 180SSJU OPERATION AND PARTS MANUAL REV 3 02 01 10 GENERATOR ASSY GENERATOR ASSY ...

Page 88: ...PAGE 88 DCA 180SSJU OPERATION AND PARTS MANUAL REV 3 02 01 10 BATTERY ASSY BATTERY ASSY ...

Page 90: ...PAGE 90 DCA 180SSJU OPERATION AND PARTS MANUAL REV 3 02 01 10 MUFFLER ASSY MUFFLER ASSY ...

Page 92: ...PAGE 92 DCA 180SSJU OPERATION AND PARTS MANUAL REV 3 02 01 10 FUEL TANK ASSY FUEL TANK ASSY ...

Page 105: ...DCA 180SSJU OPERATION AND PARTS MANUAL REV 3 02 01 10 PAGE 105 1 NOTES ...